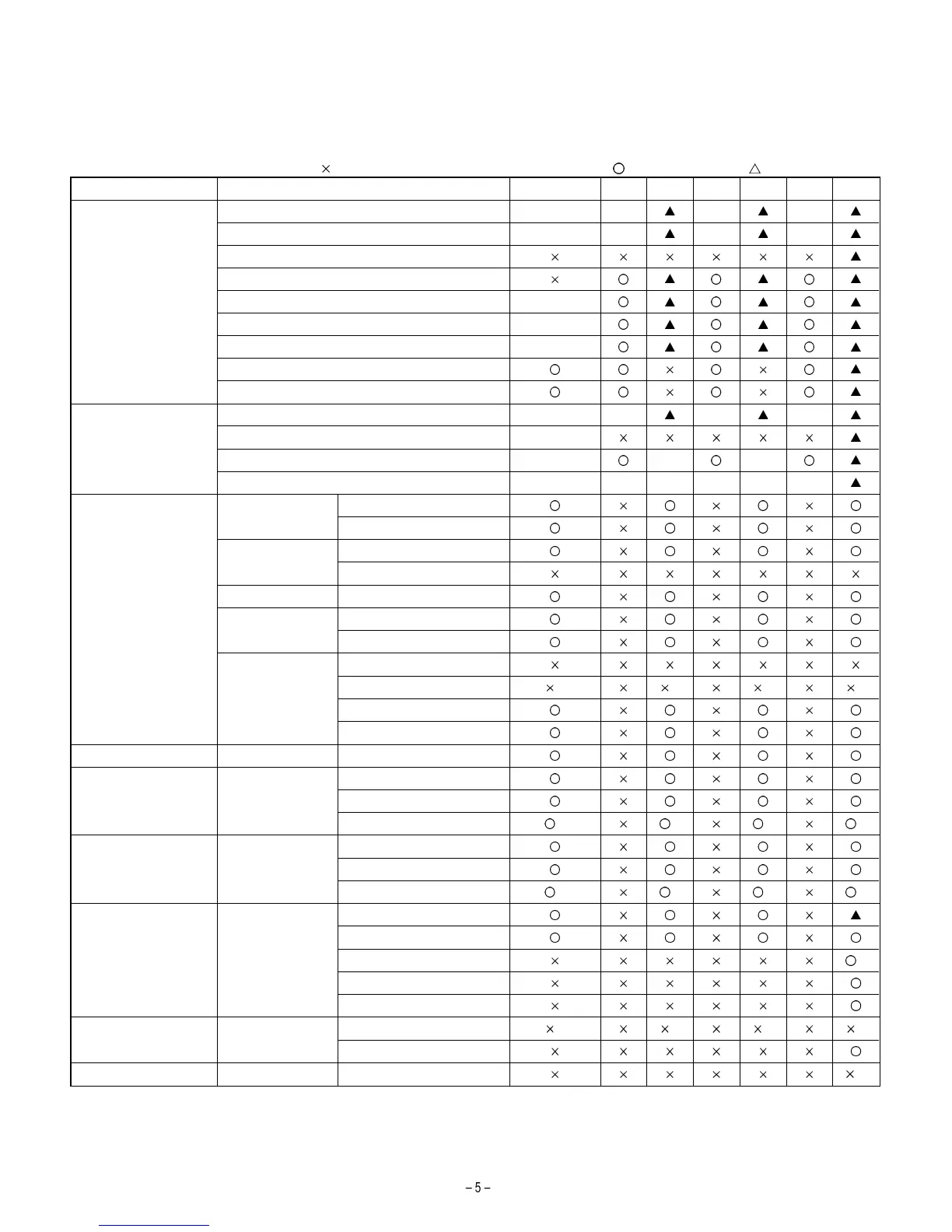

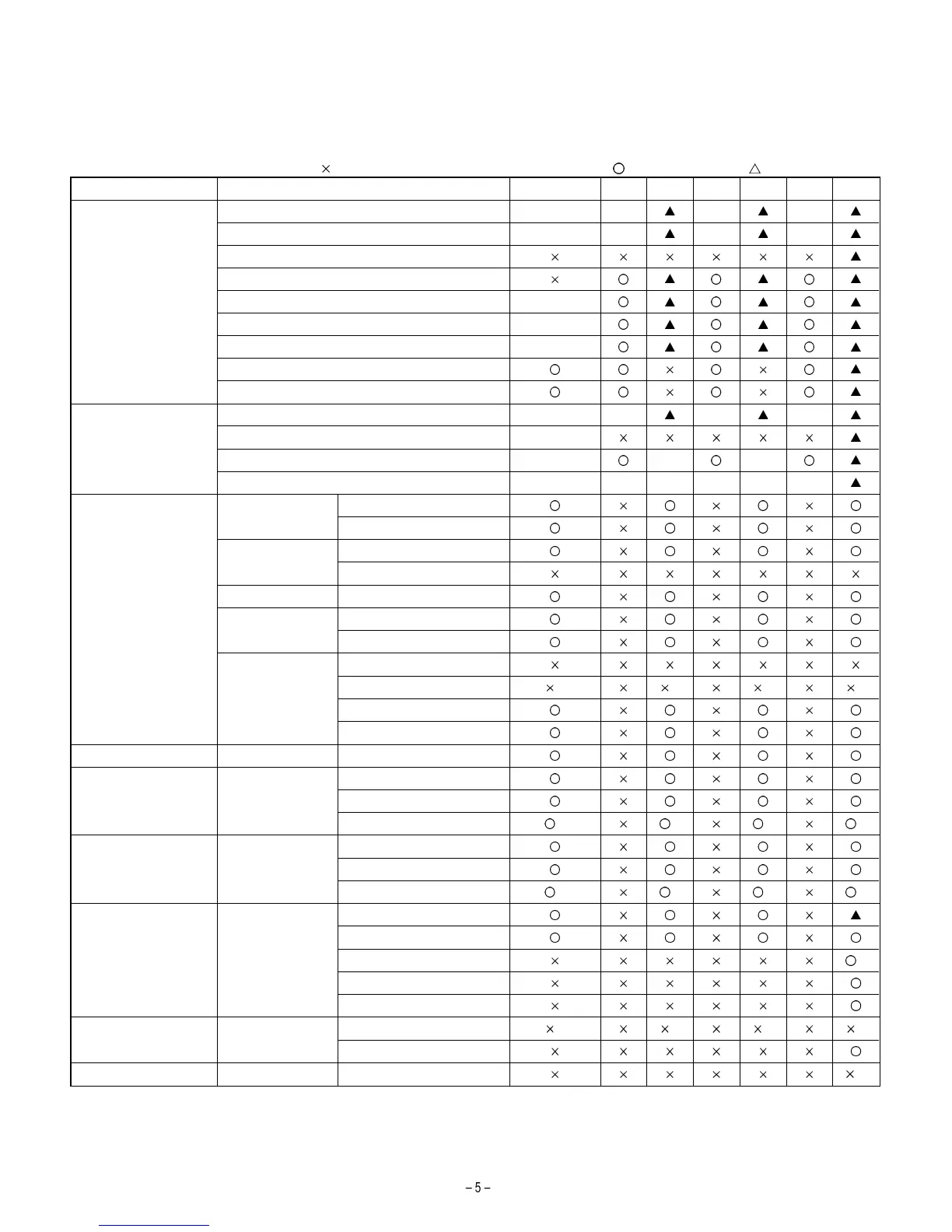

[10] MAINTENANCE

1. MAINTENANCE TABLE

: Check (Clean, adjust, or replace when required.) : Clean ▲ : Replace : Adjust ✩ : Lubricate

Unit name Part name When calling 25K 50K 75K 100K 125K 150K

Drum peripheral OPC drum – –

– –

Cleaning blade – – – –

Side seal

MC unit

(MC charging electrode) – ( )()()()()()

(MC grid) – (

)()()()()()

(MC case) – (

)()()()()()

Transfer wire

Transfer paper guide

Developing section Developer – – – –

DV seal

–

DV side seal

–

– –

Side Mylar – –––––

Optical section Lamp unit Reflector

Mirror

No. 2/3 mirror unit Mirror

Pulley

CCD peripheral Lens

Glass Table glass

White Plate

Other Drive wire

Rail

✩ ✩ ✩ ✩

Document cover

Document size sensor

LSU Dust-proof glass

Paper feed section Multi paper feed

section

Takeup roller

Paper feed roller

Spring clutch

✩ ✩ ✩ ✩

Paper transport section PS roller

Transport (paper exit) rollers

Spring clutch

✩ ✩ ✩ ✩

Fusing section Upper heat roller

Pressure roller

Pressure roller bearing

✩

Upper separation pawl

Lower separation pawl

Drive section Gears

✩ ✩ ✩ ✩

Belts

Paper exit section Ozone filter *1

*1 : Recommendable replacement time: 50K (Letter, 5% print)

Loading...

Loading...