MX-M182 MAINTENANCE 9-1

[9] MAINTENANCE

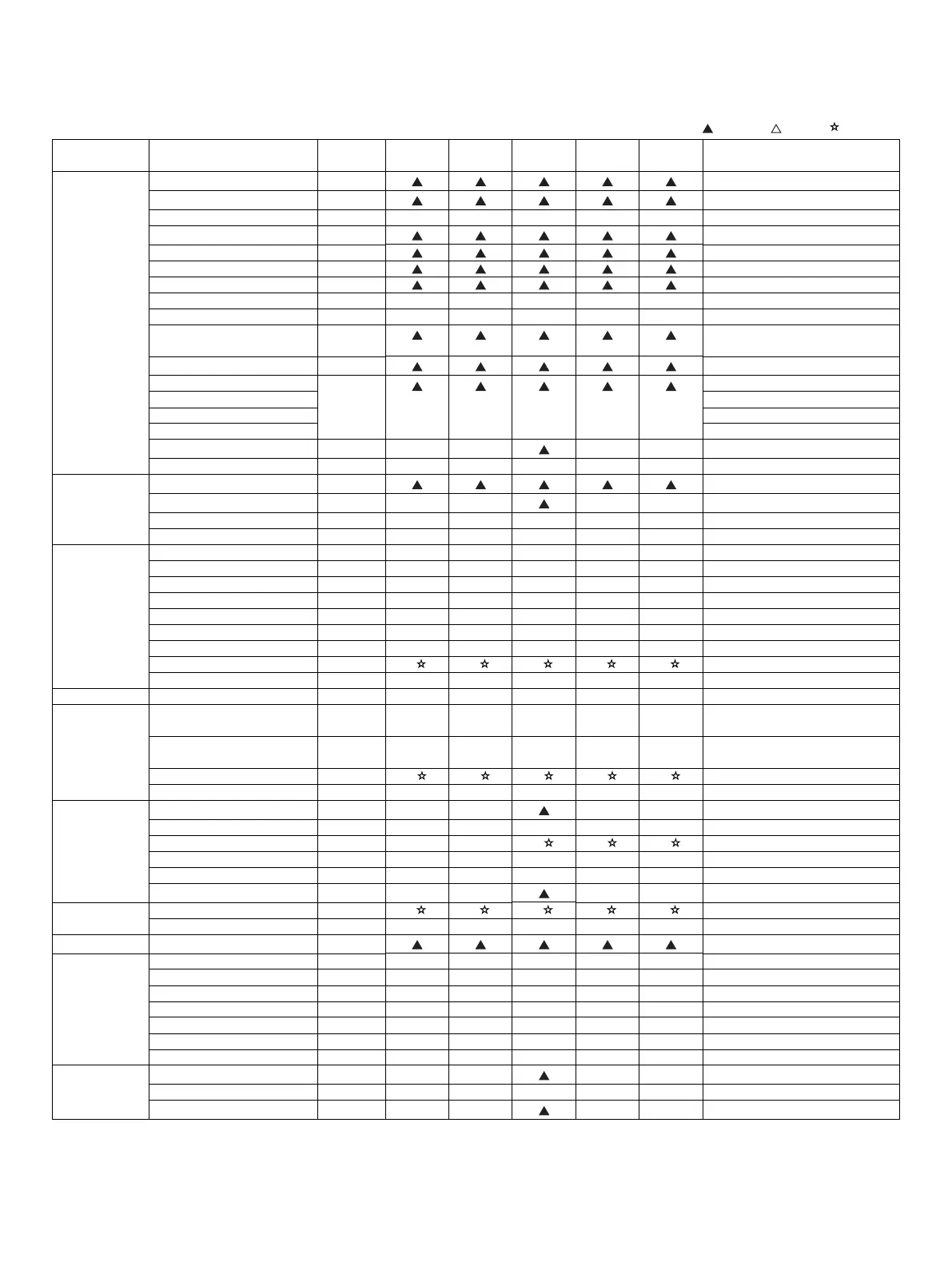

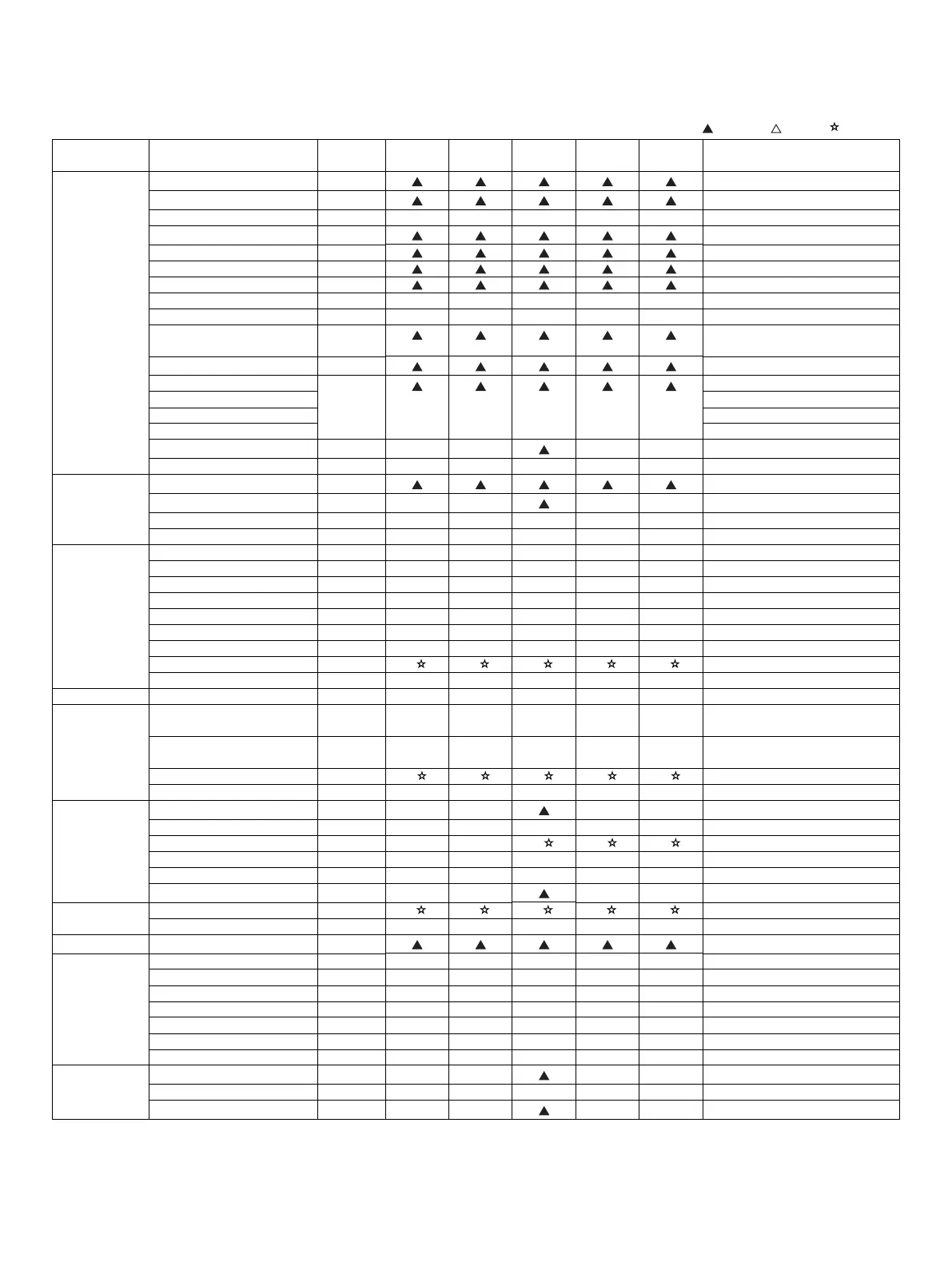

1. Maintenance table

X:Check(Clean, adjust, or replace when required.) O:Clean :Replace :Adjust :Lubricate

*1: Recommendable replacement time:50K(A4, 6%print)

*2: In maintenance cycle, after beginning to use each paper feed counter 100K, one year is a standard. Exchange when worn out.

*3: Maintenance cycle is RSPF document FEED value 100K (Sim.22-8). Or, after it begins to use it, one year is a standard. When worn out, it

exchanges it.

Unit name Part name

When

calling

50K 100K 150K 200K 250K Remark

Drum peripheral

OPC drum -

Cleaning blade -

Side seal F/R X X X X X X

MC unit X

(MC charging electrode) - ( ) ( ) ( ) ( ) ( ) Exchange if necessary

(MC grid) - ( ) ( ) ( ) ( ) ( ) Exchange if necessary

(MC case) - ( ) ( ) ( ) ( ) ( ) Exchange if necessary

Transfer wire O O O O O O

Transfer paper guide O O O O O O

MC guide seal (Cleaning

blade)

-

Drum fixing plate B X

Separation pawl X

Star ring N2

Star ring 5

Pawl holder PAN

Process frame unit X X X X X

Discharge holder O O O O O O

Developing

section

Developer X

DV seal X X X X X

Toner density sensor X X X X X X Check the sensor head surface.

DV side seal F/R X X X X X X

Optical section

Reflector O O O O O O

Mirrors - O O O O O

Pulley - X X X X X

CCD Lens - O O O O O

Table glass O O O O O O

White Plate O O O O O O

Drive wire - X X X X X

Rail - X X X X X

OC O O O O O O

LSU

Dust-proof glass O O O O O O

Paper feed

section

Manual feed take-up roller O O O O O O *2

Alcohol cleaning

Transport rollers O O O O O O *2

Alcohol cleaning

Spring clutch - O O O O O

Electromagnetic clutchs - X X X X X

Fusing section

Upper heat roller X O O O O

Pressure roller X O O O O O

Pressure roller bearing - X X O O O

Upper separation pawl X X X O O O

Lower separation pawl X X X O O O

Cleaning pad X X X X X

Drive section

Gears - X X X X X

Belts - X X O X X

Paper exit section

VOC filter - *1

Document

transport section

Pickup roller O O O O O O *3

Handling unit X X X X X X *2

Handling sheet X X X X X X

Paper feed roller O O O O O O *3

PS roller O O O O O O

Transport roller X X X X X X

Paper exit roller X X X X X X

Cassette paper

feed section

Paper feed roller X X X X X *2

Handling unit X X X X X X

Handling sheet X X X X X *2

Loading...

Loading...