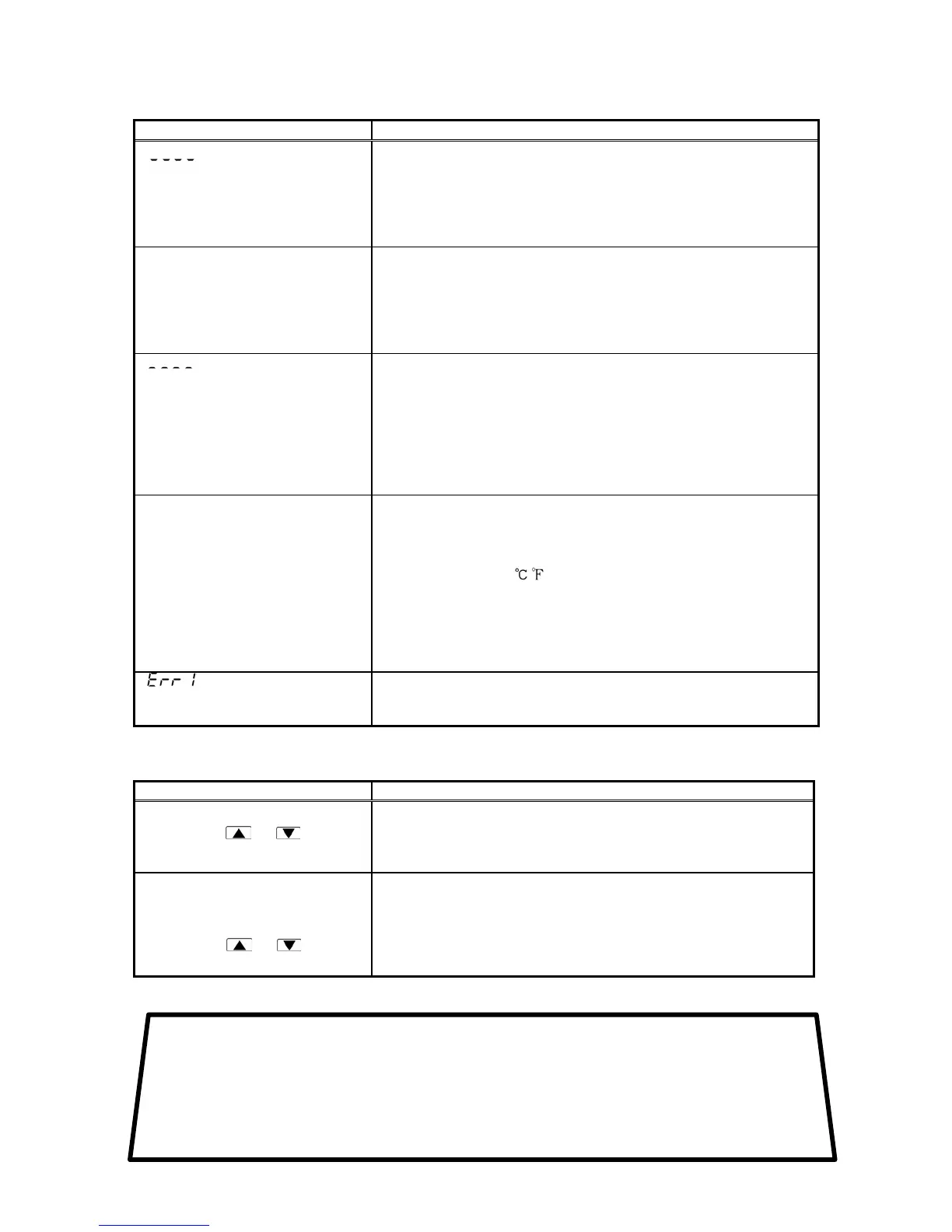

11. Troubleshooting

If any malfunctions occur, refer to the following items after checking the power supply and wiring.

11.1 Indication

Phenomenon Presumed cause and solution

“

” is blinking on the PV

display.

• Sensor (Thermocouple, RTD and DC voltage 0 to 1V DC

input) is burnt out.

Change the sensor for a new one.

• The lead wire of the sensor (Thermocouple, RTD and DC

voltage 0 to 1V DC input ) is not securely connected.

Connect it to the terminal properly.

The indication on the PV display

does not change.

• Check if the input signal source for DC voltage (0 to 10V DC)

and DC current (0 to 20mA DC) is normal.

• Is the lead wire of the sensor DC current (0 to 20mA DC) and

DC voltage (0 to 10V DC) securely connected to the terminal?

Connect the sensor lead wire securely to the instrument

terminal.

“ ” is blinking on the PV

display.

• Check if the input signal source for sensor DC current

(4 to 20mA DC) and DC voltage (1 to 5V DC) input is

normal.

• Is the input signal wire of DC current (4 to 20mA DC) and

DC voltage(1 to 5V DC) securely connected to the terminal

of this instrument?

Connect the input signal wire securely to the terminal of

the instrument.

The indication on the PV display

is abnormal or unstable.

• Is designation of the sensor input correct?

Set the correct sensor input.

• Is the polarity of the sensor input correct?

Wire it correctly.

• Temperature unit (

/ ) is mistaken.

Set the correct unit.

• AC may be leaking into the input of this controller from

thermocouple or the RTD connected to the measured object.

Keep AC from leaking into the input of this controller

from thermocouple or RTD of the measured object.

“ ” is indicated on the

PV display.

• Internal memory is out of order.

Please contact our sales branch or the shop where you

purchased this unit.

11.2 Key operation

Phenomenon Presumed cause and solution

• Setting values do not change

even if the

or key is

pressed during setting mode

• Mode1 or mode 2 is selected in setting value lock selection.

Cancel the Lock mode.

• PID auto-tuning is performing.

Cancel PID auto-tuning.

• Unable to set the value above

or below scaling high limit or

low limit within the input range

even if the

or key

is pressed.

• The value of scaling high limit setting or low limit setting in

auxiliary function setting mode 2 may be set at the point the

value does not change.

Set the proper value.

• If you have any inquiries, please consult our agency or the shop where you purchased the unit.

No.DCL31E2 Apr. 2002

SHINKO TECHNOS CO.,LTD.

OVERSEAS DIVISION

:

:

:

:

Reg. Office

Mail Address

URL

E-mail

2-48, 1-Chome, Ina, Minoo, Osaka, Japan

P.O.Box 17, Minoo, Osaka, Japan

http://www.shinko-technos.co.jp

overseas@shinko-technos.co.jp

Tel :

Fax:

81-727-21-2781

81-727-24-1760

Loading...

Loading...