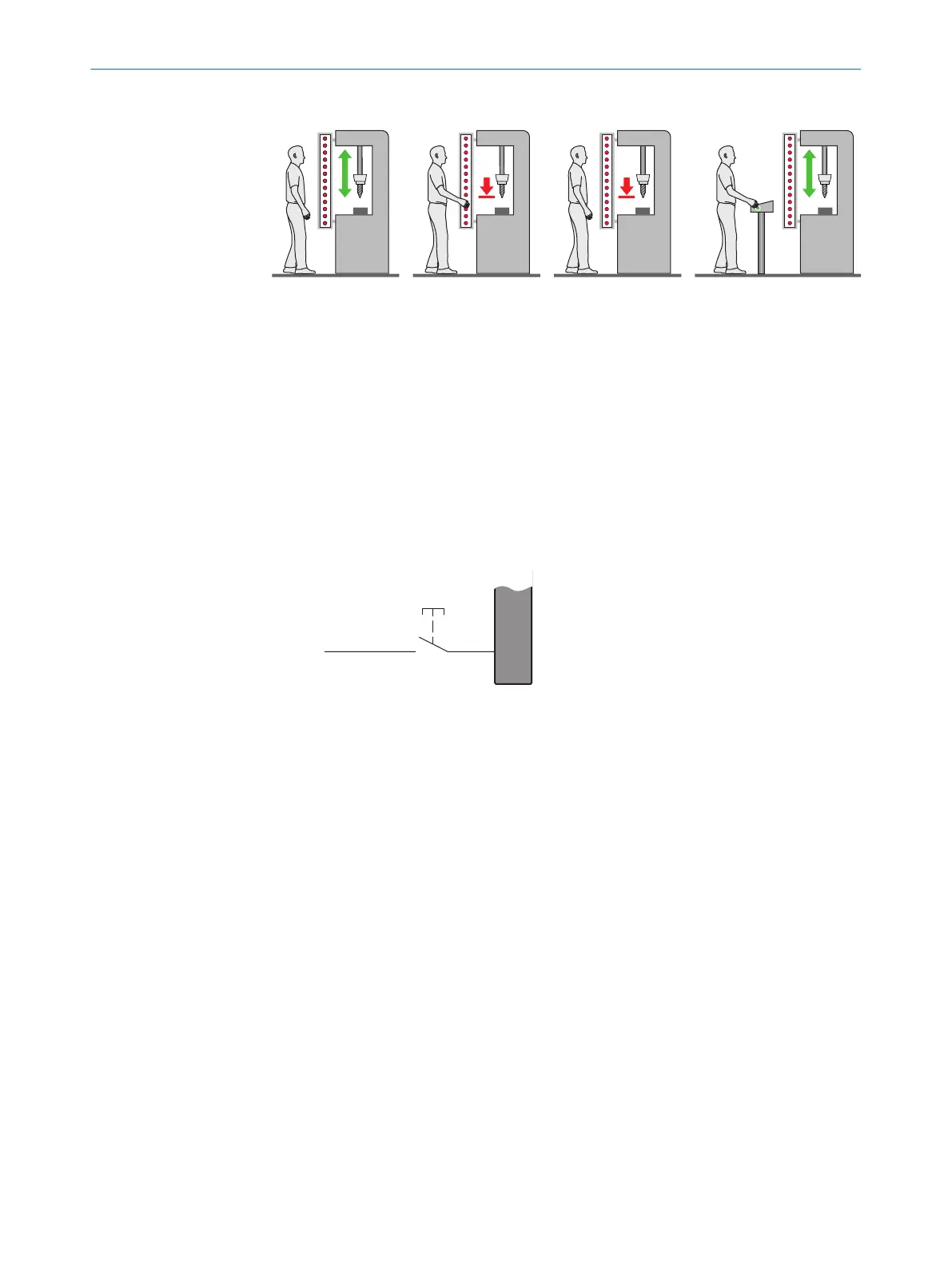

Figure 20: Schematic representation of operation with restart interlock

T

he dangerous state of the machine (!) is brought to an end if the light path is inter‐

rupted (") and is not re-enabled (§) until the operator presses the reset pushbutton

located outside the hazardous area ($). The machine can then be restarted.

Depending on applicable national regulations, a restart interlock must be available if it

is possible to stand behind the protective device. Observe IEC 60204-1.

4.4.1.1 Integrated restart interlock and reset

Prerequisites

•

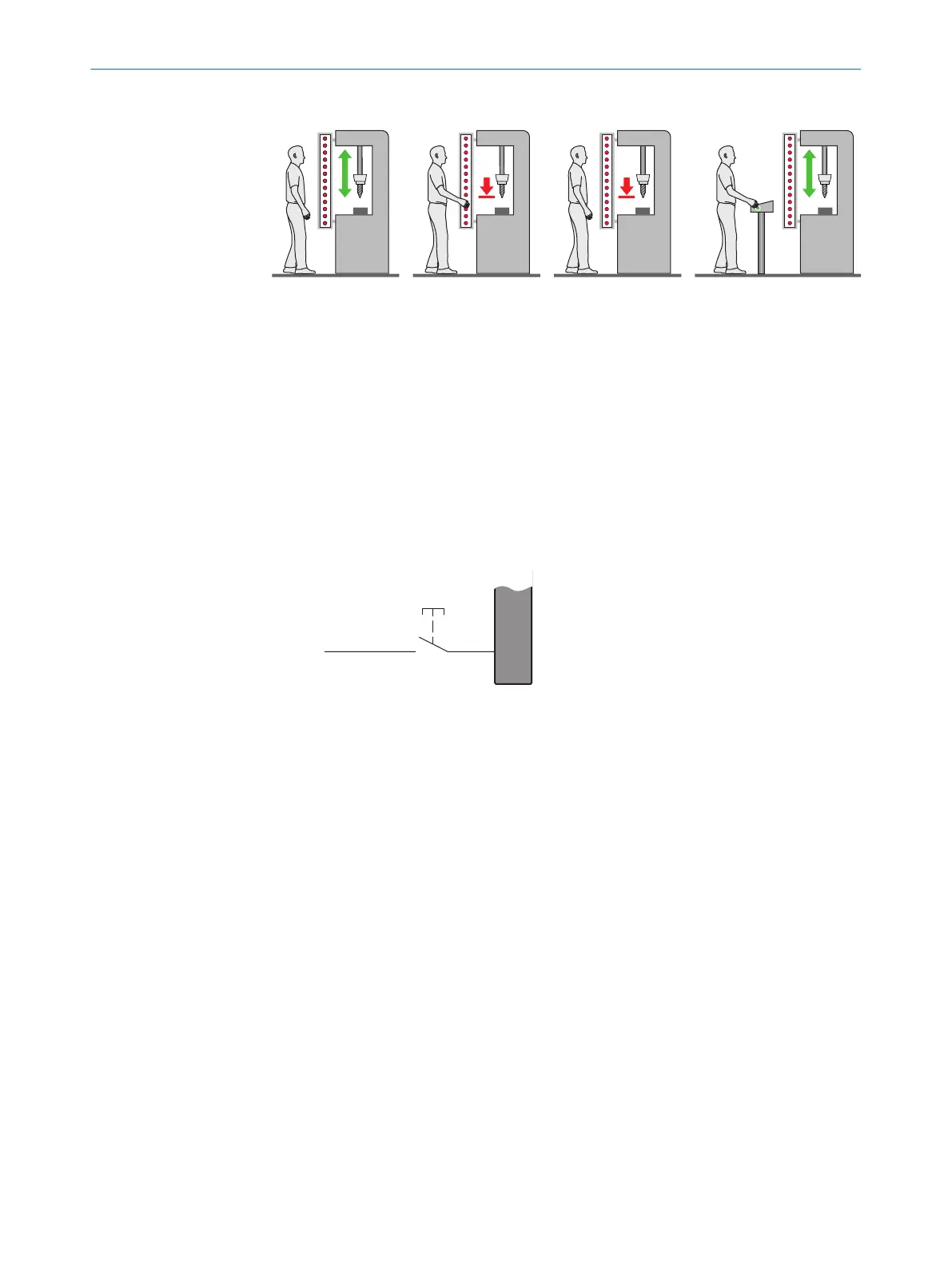

A r

eset device, such as a reset pushbutton, is connected.

Figure 21: Electrical diagram of the reset device

Using an integrated restart interlock

T

he restart interlock is configured once the reset pushbutton has been connected.

The following applies to the restart interlock:

•

If the protective field is clear once the machine has been switched on or following

an interruption, the OSSDs do not switch to the ON state

•

If someone presses the reset pushbutton and then lets go of it when the protec‐

tive field is clear, the OSSDs switch to the ON state

•

The machine may not restart yet. The operator must also press the machine start

button after having pressed the reset pushbutton.

Single system

Onl

y one reset pushbutton may be connected to a single safety light curtain.

Connection options of the reset pushbutton in the single system:

•

M12, 8-pin system connection

•

Extension connection on the receiver

Further topics

•

"C

onfiguring the restart interlock", page 56

PROJECT PLANNING 4

8027140/2021-11-04 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4

33

Subject to change without notice

Loading...

Loading...