Further topics

•

"Minimum dis

tance to reflective surfaces", page 26

9.3 Regular thorough check

The test is intended to ensure that the hazardous area is monitored by the protective

de

vice and any attempted access to the hazardous area is prevented.

b

Carry out the checks specified in the test plan of the manufacturer of the machine

and the operating entity.

9.4 LEDs

Sender

P

osition of LEDs: see "Sender displays", page 16.

Receiver

P

osition of LEDs: see "Receiver displays", page 17.

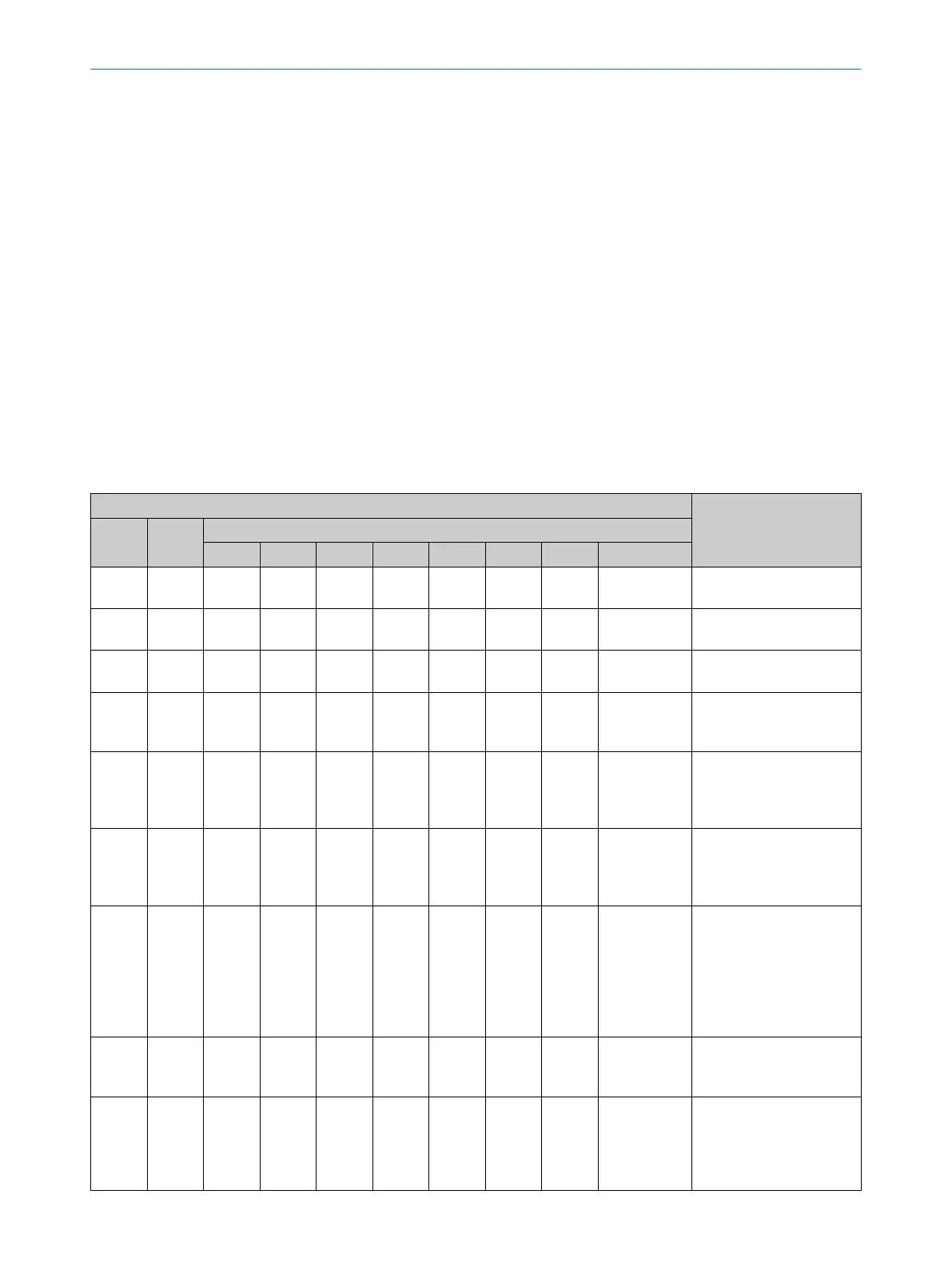

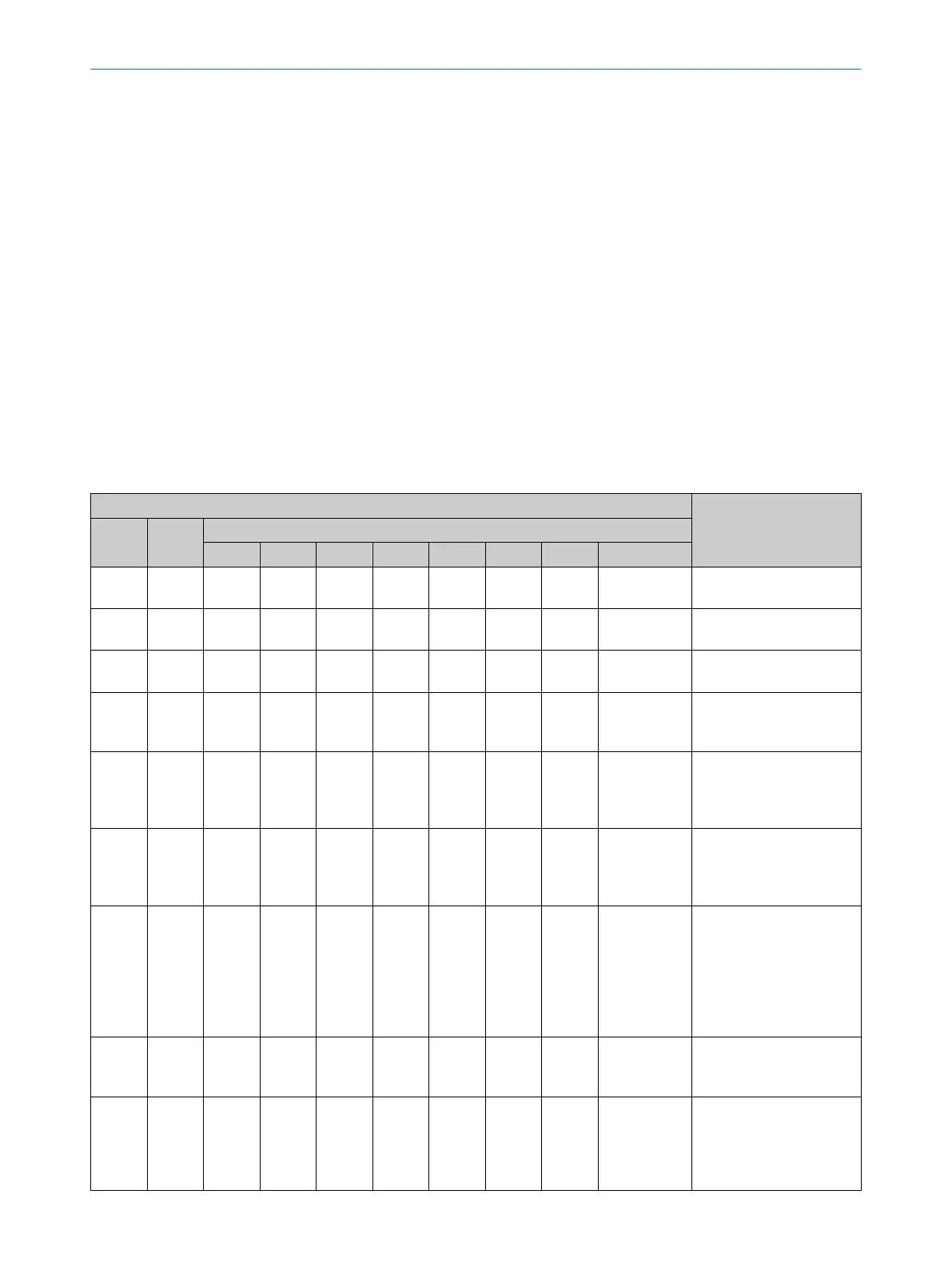

Table 20: LEDs on the receiver during normal operation

LEDs Meaning

OSSD Field Diagnostics LEDs

1 2 3 4 5 6 7 8

O

W

hite

EDM is configured.

O

W

hite

Beam coding 1 or 2 is

conf

igured.

O

W

hite

Restart interlock is config‐

ur

ed.

O R

ed Ö Ö

Yellow/

green

o o o o o o o o

Reset of the configuration

t

o factory settings is acti‐

vated.

O R

ed Ö

Green

The device is in configu‐

r

ation mode following a

change to the configura‐

tion.

O R

ed O

Green

The laser alignment aid of

t

he sender is switched on.

Its own protective field is

clear.

O R

ed O Red

Its own protective field is

int

errupted.

OR

The protective field is

clear.

The reset button has just

been actuated.

O R

ed Ö Yel‐

low

The protective field is

c

lear.

Reset required.

Ö Y

el‐

low

The reset pushbutton is

de

fective or is being actu‐

ated continuously. Check

the wiring of the reset

pushbutton.

9 OPERATION

66

O P E R A T I N G I N S T R U C T I O N S | deTec4 8027140/2021-11-04 | SICK

Subject to change without notice

Loading...

Loading...