27

8024019/AE00/V1-0/2019-02| SICK A D D E N D U M T O O P E R A T I N G I N S T R U C T I O N S | FWE200DH

Subject to change without notice

TECHNICAL DATA 7

7Technical data

7.1 Optional components

7.2 Spare parts / consumables

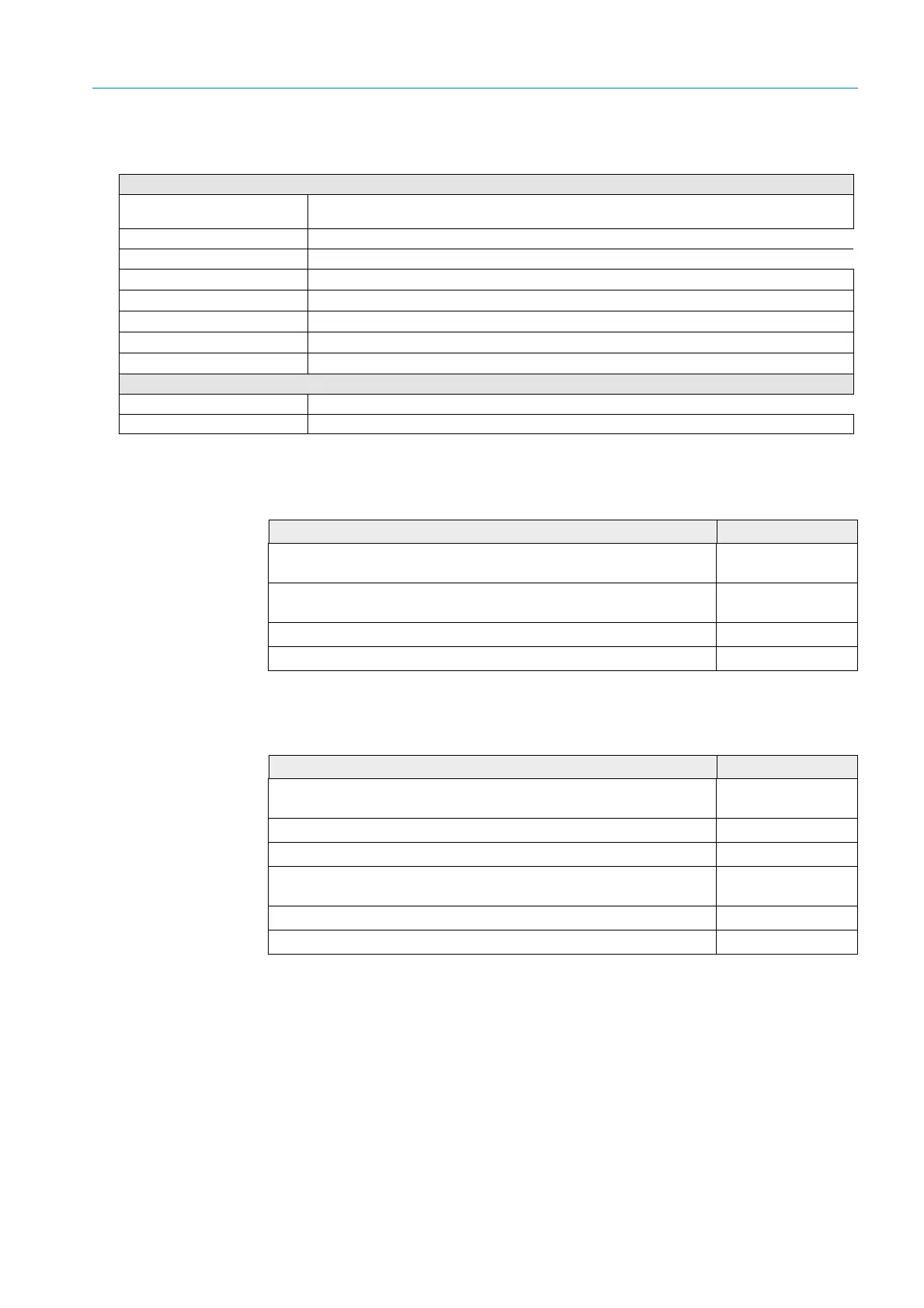

Water back purge requirements

Water quality Drinking water or purified process water (without limescale and solid residues)

Provide a pre-filter if necessary.

Water pressure Feed with 3…10 barg

Water temperature Max. 60 °C

Purging pressure

3 barg (min. 2 barg, max. 6 barg)

Water flow rate

Flow rate during purging 5 liters/min

Water requirement

Approx. 5...20 liters per purge process (depending on configuration)

Purging duration

Approx. 3…4 minutes

Purging processes

Standard 3 purges per day (configurable using a control cycle interval)

Power input

Purge air heater Max. 1 kW

Heated extraction hose Max. 0.3 kW

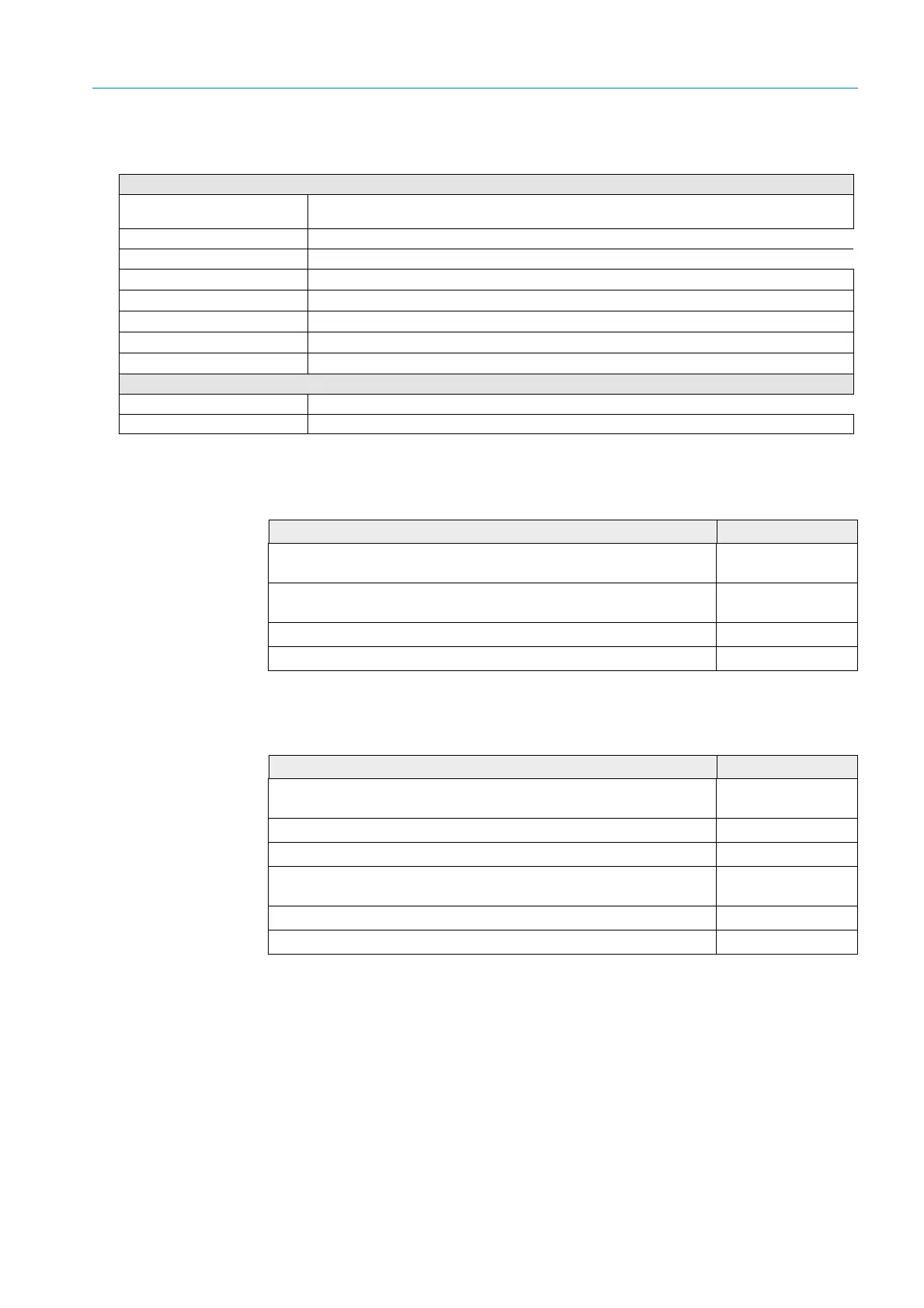

Designation Part No.

Heated extraction hose

230 V, hose 1400 mm, heat sheath 1100 mm

2082195

Heated extraction hose

115 V, hose 1400 mm, heat sheath 1100 mm

2094377

Purge air heater 230 V with accessories for assembly on SLV7 base plate 2105688

Purge air heater 115 V with accessories for assembly on SLV7 base plate 2106812

Designation Part No.

WBP control block WBP: 2× solenoid valves incl. hose connection and pressure

reducer with filter and base plate

2106005

Hose set: 2 m blue hose 2106006

WBP swirl chamber cover incl. baffle plate 2106007

WBP ball valve connection set; connection for purge air hose at top and bottom

of WBP ball valve (material: PTFE)

2106008

WBP ball valve WBP: Incl. line for control cabinet and 2× solenoid valve plugs 2106071

Water filter 5340636

Loading...

Loading...