8014640/YWI5/2016-08-08 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 2LECTOR62X | SICK

Mounting device

1. Perform one of the following steps:

• Mount the device on a bracket supplied by the

customer using M5 screws. To do this, either

use the threaded mounting holes in the hous-

ing in pairs at the front or below or use the two

M5 sliding nuts in the lateral slots. Mounting

bracket no. 2042902 can be attached at the

bottom or on the sliding nuts. Screw the screws

no more than 5 mm into the blind tapped

holes. - Dimensional drawings, see “Setup

and function” on page 4.

• Attach the SICK bracket that has been or-

dered separately (e.g., mounting bracket no.

2042902) to the sensor using the two sliding

blocks. Refer to the “Mounting” chapter of the

Technical Information “Image-Based Code

Reader” Lector620.

Aligning the device plus reading window with

the code

Remember to consider the shape and alignment of

the eld of view in front of the device.

Fig. 1: Example for eld of view and reading eld, size

elongation depends on device

1. Working distance

2. Field of view (area at a certain working distance)

3. Reading eld (depth of eld)

Taking account of the working distance, depending

on the resolution

• Using the Auto-Setup function, the Lector620

automatically adjusts its focal position to suit the

working distance from the code.

• ECO variant: The focal position is set by entering

the working distance in SOPAS.

Variant-dependent visual and reading eld diagrams

can be found on the SICK product page in the web:

www.sick.com/lector62x

Maximum working distance with minimum resolution

Max. working distance

[mm]

Minimum resolution [mm]

50 0.10

105 0.20

160 0.30

220 0.40

270 0.50

330 0.60

380 0.70

Tab. 1: Example: Working distances of Professional variant

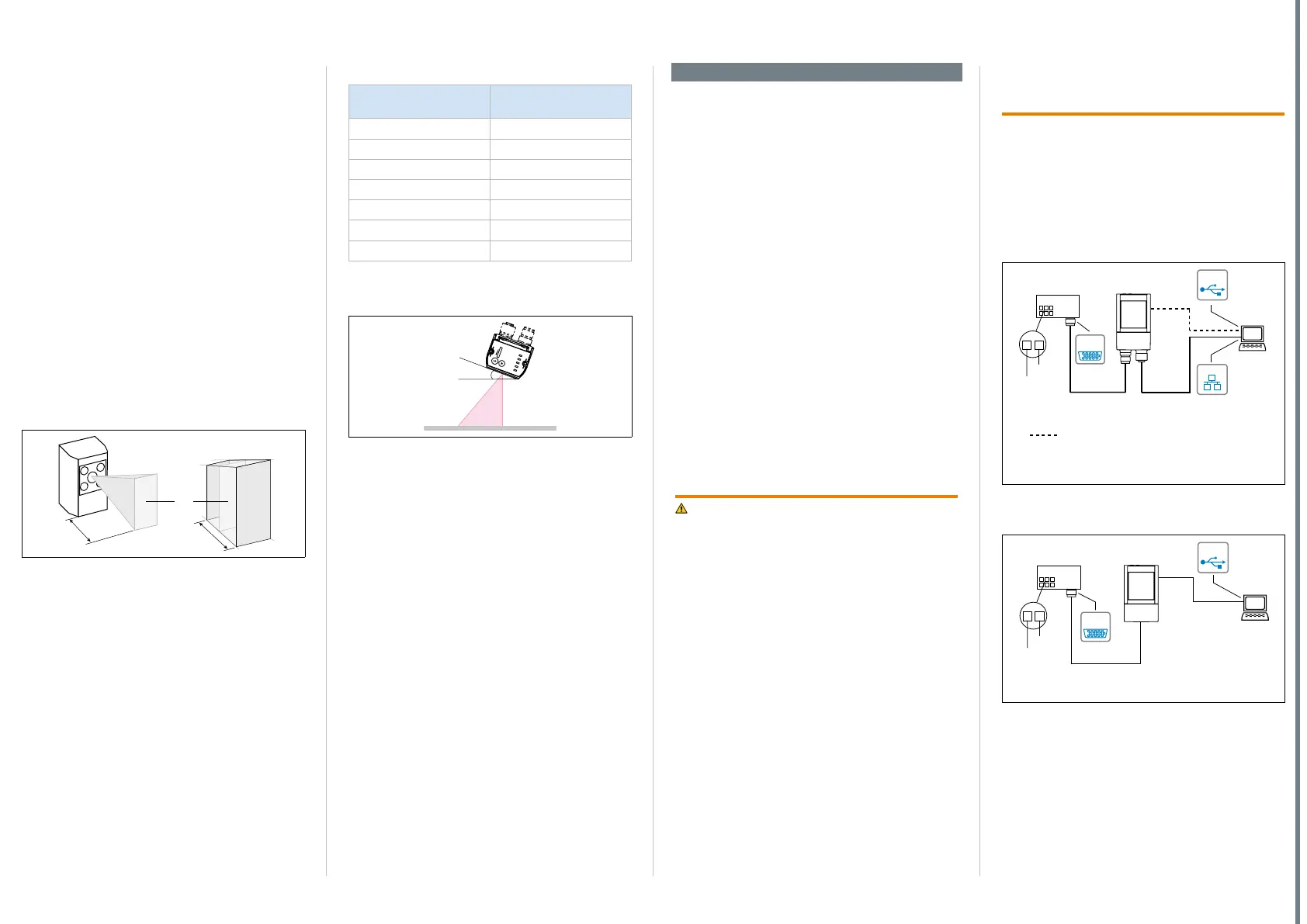

Allowing for reading angle

typical 20°

Fig. 2: Selection of the skew angle, depending on the

application

Tilt the device away from the plane that is per-

pendicular to the surface of the code to avoid as

many interfering reections as possible. Typically,

this angle will be between 10° and 20°. In the

case of codes created on metal, e.g., by dot peen-

ing, an angle of between 0° (bright eld light) and

45° (dark eld light) may be advisable.

Mounting the CDB connection module

These operating instructions describe the commis-

sioning of the CDB620-001 connection module. For

more information, see Operating instructions

“CDB620-001 connection module operating instruc-

tions” (no. 8012119). Alternatively, you can use the

CDB650-204 connection module.

Mount the connection module in the vicinity

of the device. If you are using the serial data

interface (RS-232), the maximum recommended

distance is 5 m.

Mount the connection module in such a way that

the Lector620 remains accessible at all times.

Step 2: Electrical installation

• The electrical installation must only be per-

formed by electrically qualied persons.

• Standard safety requirements must be met when

working on electrical systems.

• Electrical connections between the Lector620 and

other devices may only be created or disconnected

when there is no power to the system. Otherwise,

the Lector620 and devices may be damaged.

• When using connecting or extension cables with an

open end, make sure that bare wire ends are not

touching (risk of short-circuit when the supply volt-

age is switched on). Wires must be appropriately

insulated from each other.

• Wire cross-sections in the supply cable from the

customer's power system must be designed in ac-

cordance with the applicable standards.

• If the supply voltage for the Lector620 is not

supplied via the optional CDB620-001 connec-

tion module, the Lector620 must be protected by

a separate max. 2 A slow-blow fuse in the supply

circuit.

• All circuits connected to the Lector620 must be de-

signed as SELV circuits. The power supply or power

supply unit must satisfy SELV requirements in ac-

cordance with the currently applicable EN 60950-1.

(SELV = Safety Extra Low Voltage).

WARNING

Risk of injury and damage caused by electrical

current!

The Lector620 is designed to be operated in a system

with professional grounding of all connected devices

and mounting surfaces to the same ground potential.

Incorrect grounding of the Lector620 can result

in equipotential bonding currents between the

Lector620 and other grounded devices in the system.

This can lead to hazardous voltages being applied to

the metal housing, cause devices to malfunction or

sustain irreparable damage, and damage the cable

shield as a result of a heat increase, causing cables

to set alight.

Ensure that the ground potential is the same at all

grounding points.

If the cable insulation is damaged, disconnect the

supply voltage immediately and have the damage

repaired.

For measures for eliminating hazards, see Chapter

“Electrical installation”, in the Technical Informa-

tion “Image-based code readerLector620”.

1. Connect the communication interface of the

Lector620 to the PC (Ethernet or USB, depending

on model).

2. Supply power to the Lector620 according to the

type label.

- For an overview of all interfaces and connection

options, see “Overview of all interfaces and connec-

tion options” on page 7.

Connection module

CDB620-001

SOPASSOPAS

Lector

®

620

1

2

... 30 V

GND

Image

display

Diagnostcis

“Power”

“Ethernet”

“USB”

ICR620x-xxxYxx (Y = 5)

Swivel connector unit with 2 M12 cylindrical connectors

e.g. cable

no. 2055419

(2 m)

e.g. cable

no. 6034414

(2 m)

SerialSerial

...

...

alternative for configuration/image display,

e.g. cable no. 6036106 (2 m)

EthernetEthernet

USBUSB

Fig. 3: Connection block circuit diagram for Lector620

Professional, High Speed, DPM Plus and OCR with

swivel connector

Connection module

CDB620-001

SOPASSOPAS

Lector

®

620 ECO

1

2

V

GND

Image

display

Diagnostics

“Power”

SerialSerial

...

...

e.g. cable

no. 6036106

(2 m)

ICR620x-xxxYxx (Y = 0)

Cable with 15-pin D-Sub HD male connector

“USB”

USBUSB

Fig. 4: Connection block circuit diagram for Lector620 ECO

with cable outlet

Loading...

Loading...