62/69

Siemens Building Technologies Electronic Air / Fuel Ratio Control System CC1P7873.1en

HVAC Products 18 Notes on the commissioning of a burner 15.10.2002

B. Curve adjustment by O2 value with the help of an auxiliary table (e.g. for 17

curvepoints, see below)

(less accurate, but quicker)

Procedure (e.g. highlighted table column)

1. Determine the amount of fuel at maximum burner output and set it. Set the fan

speed to the required O

2 setpoint (e.g. 2.20 %).

2. Set the RVW25... and the RVW26… to the next lower loadpoint (93.7 %) while

maintaining the positions for fuel and air. Here, warning «-58 / Monoton fail») will

be delivered. Ignore this message when making the next settings.

3. Reduce the amount of fuel until the O

2 value (3.37 %) listed in the table for this

load point (93.7 %) is reached.

4. Reduce the air volume until the demanded O

2 setpoint is reached. This can be ei-

ther the O

2 value of the table column used until now (2.2 %) or the value of another

column (e.g. 2.40 %). Warning «-58») must now disappear within 20 to 30 sec-

onds.

5. Repeat steps 2 through 4 until the minimum burner output is reached.

6. Interpolate the curvepoints below the low-fire position values (e.g. 0 %).

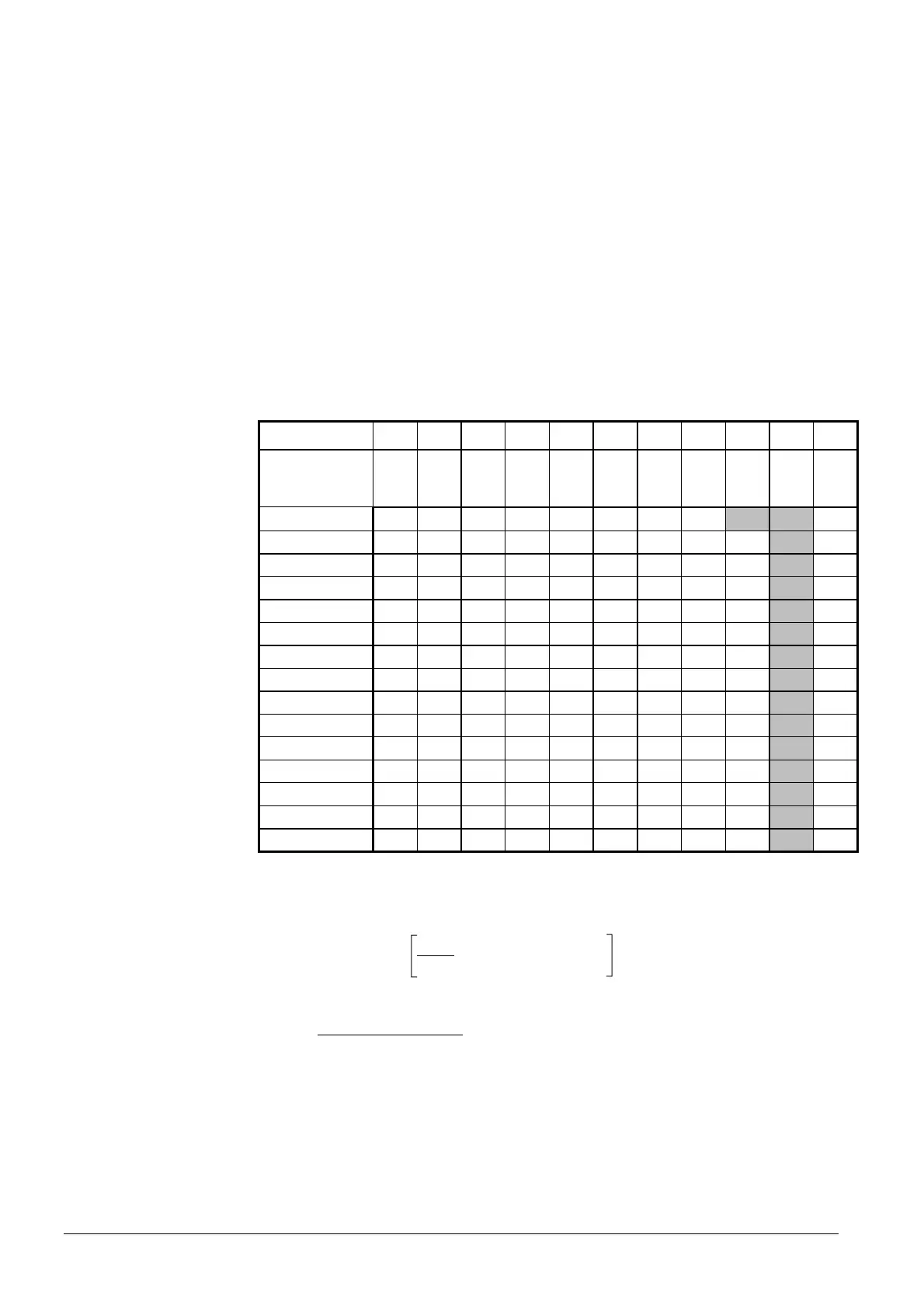

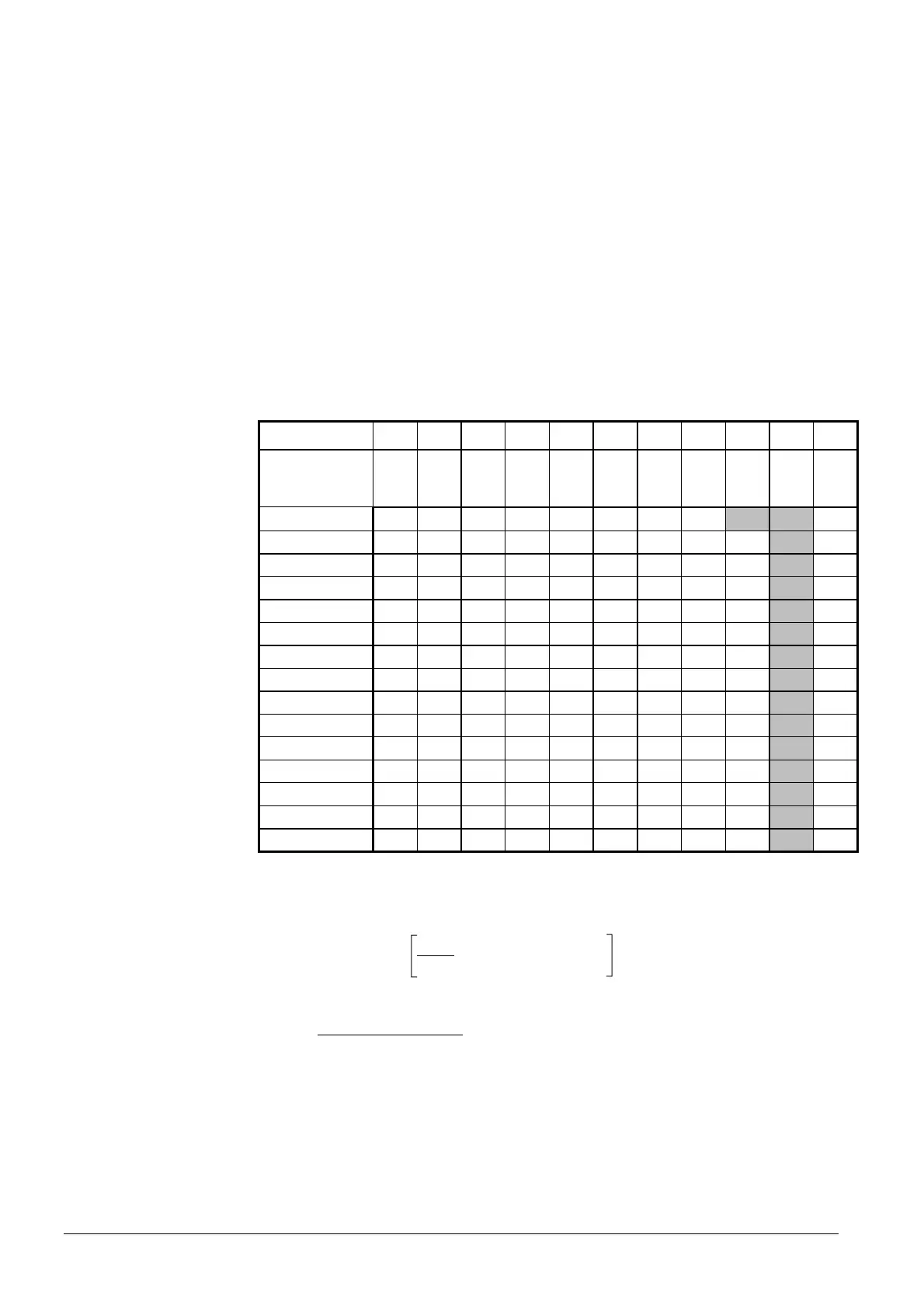

O2 setpoint [%]

4.00 3.80 3.60 3.40 3.20 3.00 2.80 2.60 2.40 2.20 2.00

Number (l)

Output (P) [%]

1.24 1.22 1.21 1.19 1.18 1.17 1.15 1.14 1.13 1.12 1.11

100 4.00 3.80 3.60 3.40 3.20 3.00 2.80 2.60 2.40 2.20 2.00

93.75 5.06 4.87 4.68 4.49 4.31 4.12 3.93 3.74 3.56 3.37 3.18

87.50 5.13 4.94 4.75 4.57 4.38 4.19 4.01 3.82 3.63 3.46 3.26

81.25 5.21 5.02 4.84 4.65 4.46 4.28 4.09 3.91 3.72 3.54 3.35

75.00 5.30 5.12 4.93 4.75 4.56 4.38 4.19 4.01 3.82 3.64 3.45

68.75 5.41 5.23 5.04 4.86 4.68 4.49 4.31 4.13 3.94 3.76 3.58

62.50 5.54 5.35 5.17 4.99 4.81 4.63 4.45 4.26 4.08 3.90 3.72

56.25 5.69 5.51 5.33 5.15 4.97 4.79 4.61 4.43 4.25 4.07 3.89

50.00 5.88 5.70 5.52 5.34 5.17 4.99 4.81 4.63 4.46 4.28 4.10

43.75 6.11 5.94 5.76 5.59 5.41 5.24 5.06 4.89 4.71 4.54 4.36

37.50 6.41 6.24 6.07 5.90 5.73 5.56 5.39 5.21 5.04 4.87 4.70

31.25 6.82 6.65 6.48 6.32 6.15 5.98 5.82 5.65 5.48 5.32 5.15

25.00 7.38 7.22 7.06 6.90 6.74 6.58 6.42 6.26 6.10 5.94 5.78

18.75 8.23 8.08 7.93 7.78 7.63 7.48 7.33 7.18 7.03 6.87 6.73

12.50 9.63 9.50 9.37 9.23 9.10 8.97 8.83 8.70 8.57 8.43 8.30

Procedure:

1. Consider the admissible range of curvepoints

2. Calculate the O

2 table values:

O2new = 20.9 % - x (20.9 % - O2 setpoint)

Pnew

Pold

3. Calculate the air number (l):

=

20.9 %

(20.9 % - O2 setpoint)

l

O2 setpoint O2 table value of the load (P = 100 %)

O

2new O2 value after fuel reduction

Pnew Required load value after fuel reduction

Pold Current load value before fuel reduction

Creating the

auxiliary table

Legend

Loading...

Loading...