59 / 100

Siemens Commissioning Guide CM1G5192en

Building Technologies 9 Display messages 29.07.2010

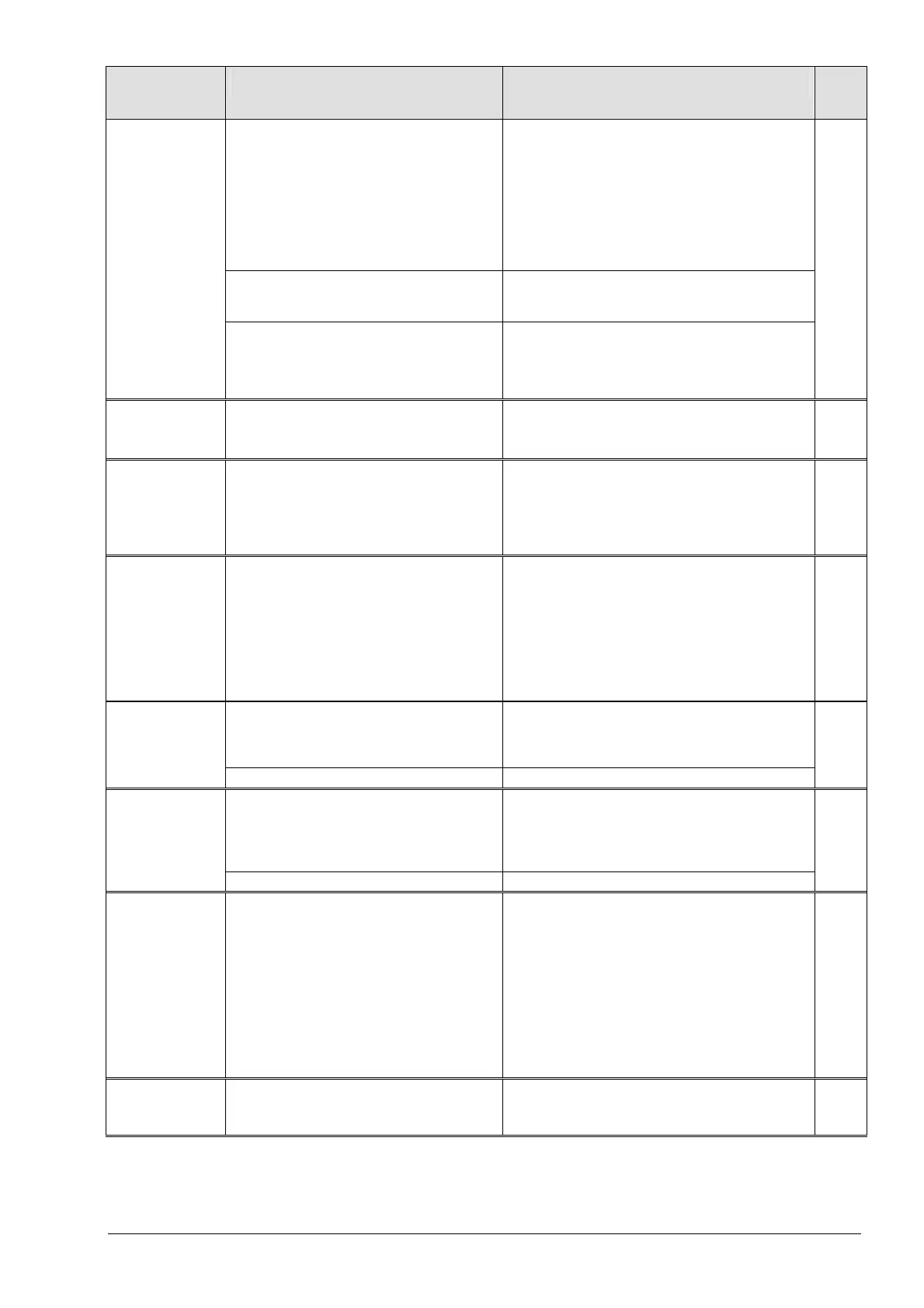

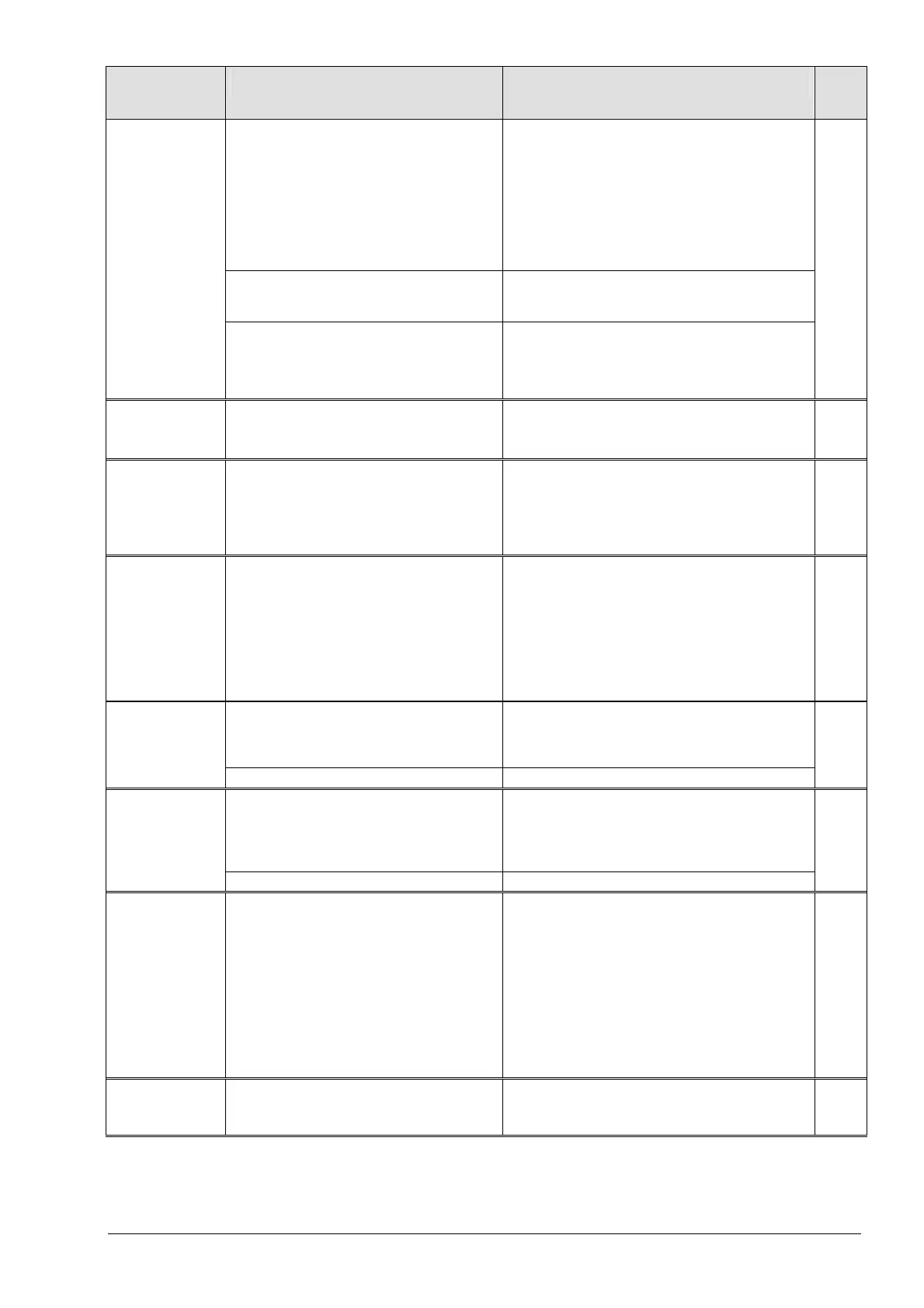

Error Cause Diagnostics and troubleshooting Res-

ponse

One or several phases at the VSD’s output

interrupted. Motor cable or motor defective

− Check the connection between VSD and motor

− If the fault occurs constantly, disconnect the motor

cable from the VSD and start the VSD without

having the motor cable connected. If the fault still

occurs, there is a defect inside the VSD, which

means that the VSD must be replaced. If the fault

does not occur without having the motor connected,

the motor cable or motor causes the fault. Connect

the motor cable (without motor) to the VSD, enabling

you to check the condition of the motor cable

Wrong motor data in commissioning parameter

entered

− Check the motor data entered for quick

commissioning

− Make automatic motor identification (refer to section 6.6)

F0023

Fault at VSD

output

Asymmetric motor currents Only if the VSD, the motor and the motor cable have

been checked (no faults detected) and the motor

temperature is monitored by an additional temperature

sensor (e.g. PTC), can the fault be hidden on the VSD

via parameters P2100[0] = 23 and P2101[0] = 0

OFF2

F0024

Rectifier

overtemperature

See F0004

OFF2

F0035

Automatic

restart after

n attempts

aborted

After “n“ unsuccessful restart attempts (P1211),

function “Automatic restart“ was aborted

− This fault is caused by some other fault, which led to

shutdown and which must be rectified first. The error

code of the initial fault, which led to the restart, is

stored in parameter r0947, index 001

− Check the settings of function “Automatic restart“

using parameters P1210 - P1213

OFF2

F0041

Automatic

motor data

identification

failed

Automatic motor identification (Mot-ID) could not

be successfully completed (see section 6.6)

− Automatic motor identification must NEVER be

aborted by an OFF command

− Check to see if the motor data in P304 - P311 are

correct

− Check to see which type of motor connection is

required (star or delta)

− Check to see if the motor is correctly connected to

the VSD

− Check the condition of motor cable and motor

OFF2

Read or write process during storage of non-

volatile parameters failed

− A reset to the default values cancels all undesired

parameter settings and retrieves the default settings.

The VSD must be recommissioned

− Replace the VSD

F0051

Parameter

EEPROM fault

Firmware installed < V1.20 Install V1.41 or higher

OFF2

Read process of power stack information failed,

or invalid data

− Firmware version (r0018) must be 1.17 or higher

− A reset to the default values cancels all undesired

parameter settings and retrieves the default settings.

The VSD must be recommissioned

− Replace the VSD

F0052

Power stack

fault

Firmware installed < V1.20 Install V1.41 or higher

OFF2

F0053

I/O EEPROM

fault (I/O board)

Read process in connection with E/A EEPROM

information failed or invalid data

− Check the rigidity and proper fitting of the I/O board.

Is the component correctly plugged in and

connected?

− Check ASN of the I/O board. Is it an SED2 I/O board

(SED2-IOBD1)?

− A reset to the default values cancels all undesired

parameter settings and retrieves the default settings.

The VSD must be recommissioned

− When above points have been checked and

complied with, the I/O board must be replaced, or

the fault can be hidden on the VSD via parameters

P2100[0] = 54 and P2101[0] = 0

OFF2

F0054

Wrong I/O print

(I/O board)

No ID on I/O board found See F0053

OFF2

Loading...

Loading...