61 / 100

Siemens Commissioning Guide CM1G5192en

Building Technologies 9 Display messages 29.07.2010

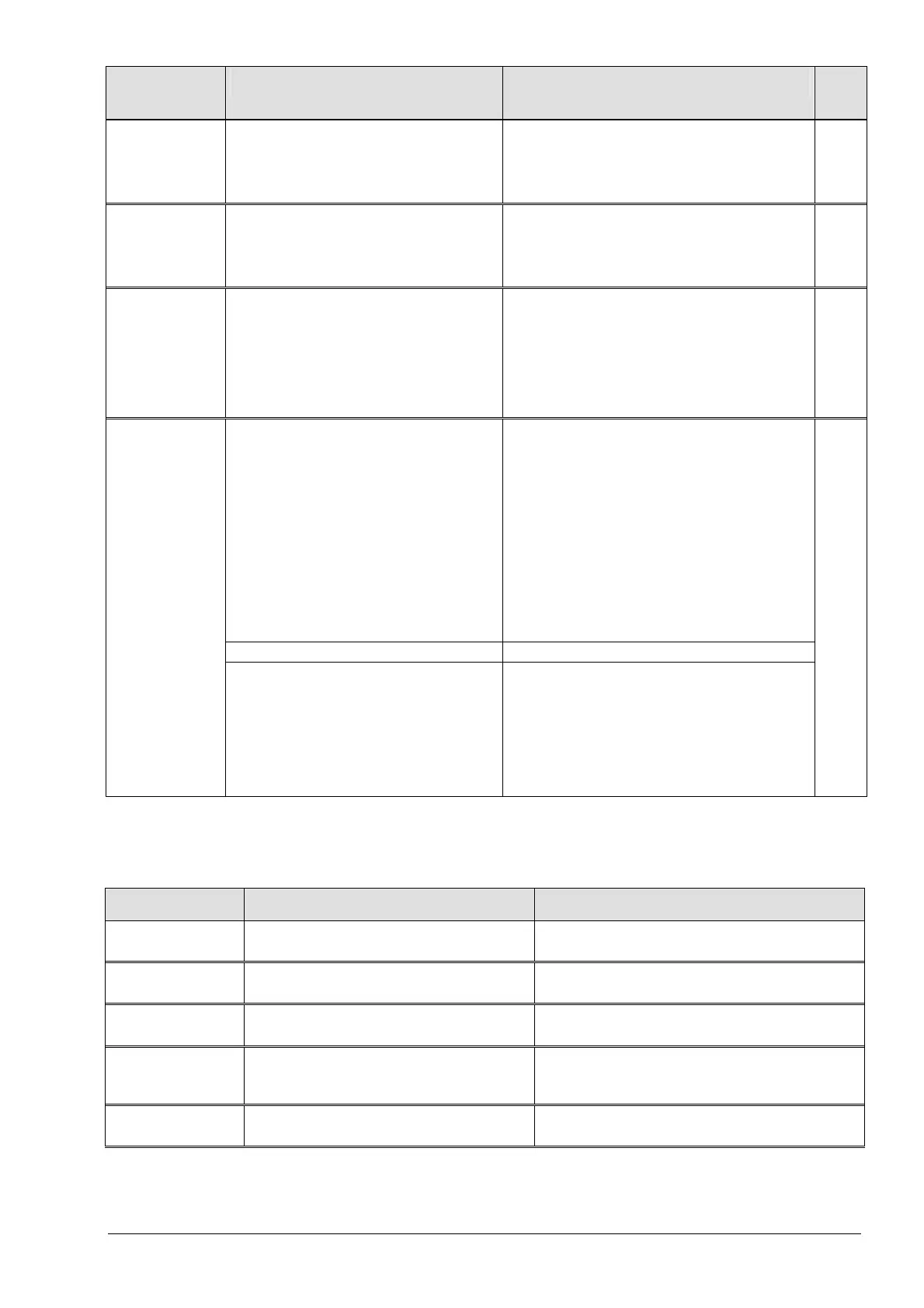

Error Cause Diagnostics and troubleshooting Res-

ponse

F0221

PID feedback

below min.

value

PID feedback below minimum value of P2268

− Check settings of the VSD’s PID control loop

− Change the value of P2268

− A reset to the default values cancels all undesired

parameter settings and retrieves the default settings.

The VSD must be recommissioned

OFF2

F0222

PID feedback

above max.

value

PID feedback above maximum value of P2267

− Check the settings of the VSD’s PID control loop

− Change the value of P2267

− A reset to the default values cancels all undesired

parameter settings and retrieves the default settings.

The VSD must be recommissioned

OFF2

F0450

BIST tests

failure

VSD self-test failed. Cause can be found based

on error value in parameter r0949:

r0949 = 1 Tests on power section failed

r0949 = 2 Tests on control section failed

r0949 = 4 Function tests failed

r0949 = 8 Tests on I/O module failed

r0949 = 16 Error of internal RAM test when

switching on

− Switch the VSD off and on again

− A reset to the default values cancels all undesired

parameter settings and retrieves the default settings.

The VSD must be recommissioned

− If the fault cannot be rectified by making a reset to

the default settings, the VSD must be replaced

OFF2

Belt failure detection without sensor (refer to

section 8.1)

− Check the settings of the following parameters and

compare them with the torques currently measured

via parameter r0031:

P2182 (frequency theshold f1)

P2183 (frequency theshold f2)

P2184 (frequency theshold f3)

P2185 (upper torque threshold 1)

P2186 (lower torque threshold 1)

P2187 (upper torque threshold 2)

P2188 (lower torque threshold 2)

P2189 (upper torque threshold 3)

P2190 (lower torque threshold 3)

P2192 (time delay load torque supervision)

− Tolerance bands of more than 50% must be set,

depending on the type of application

Belt faulty Check position and strength of the belt

F0452

Belt failure

detected

Belt failure detection with sensor (refer to

section 8.2)

− Check to ensure that the sensor is correctly

connected to digital input # 5

− Check settings of the following parameters:

− P0400 type of sensor

− P0409 (pulses / s at rated speed)

− P2181 (triggering conditions)

− P2191 (speed supervision tolerance)

− P2192 (time delay for P2191)

OFF2

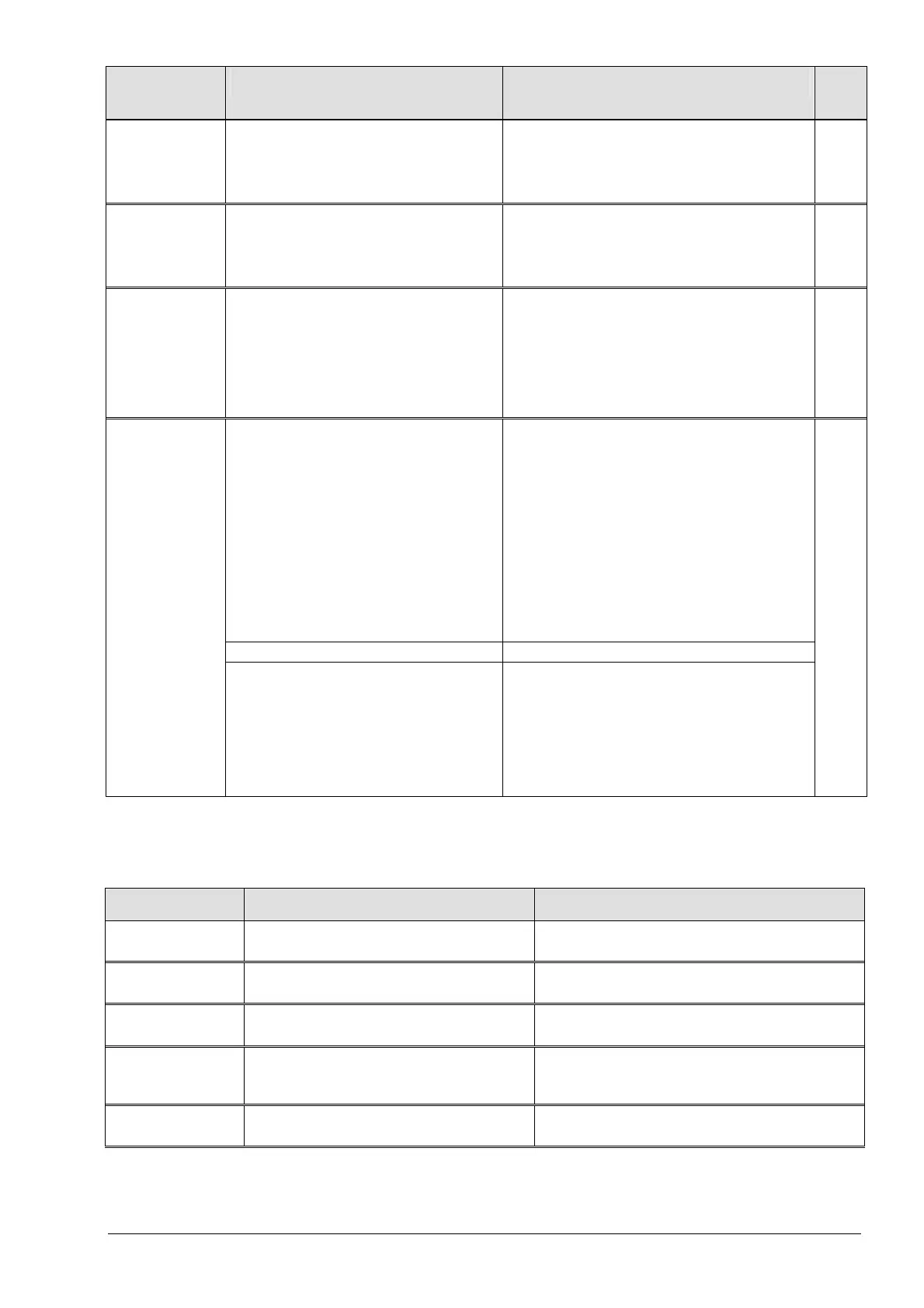

9.2 Warning code list

Error Cause Diagnostics and troubleshooting

A0501

Current limit

See F0001

A0502

Overvoltage limit

See F0002

A0503

Undervoltage limit

See F0003

A0504

VSD over-

temperature

See F0004

A0505

VSD I

2

t

See F0005

Loading...

Loading...