SIMATIC S7 - an Overview

1-8

Automation System S7-400 Configuration and Use

A5E0044271 1-02

1.4 S7-400 - Configuration Variants

Configuration Variants for various Automation Task

There is a suitable solution for every automation task. This means to cover a large

range of demands for quantity and connection with the process by choosing the

appropriate configuration variant.

Table 1-2 provides examples of configuration variants of the S7-400.

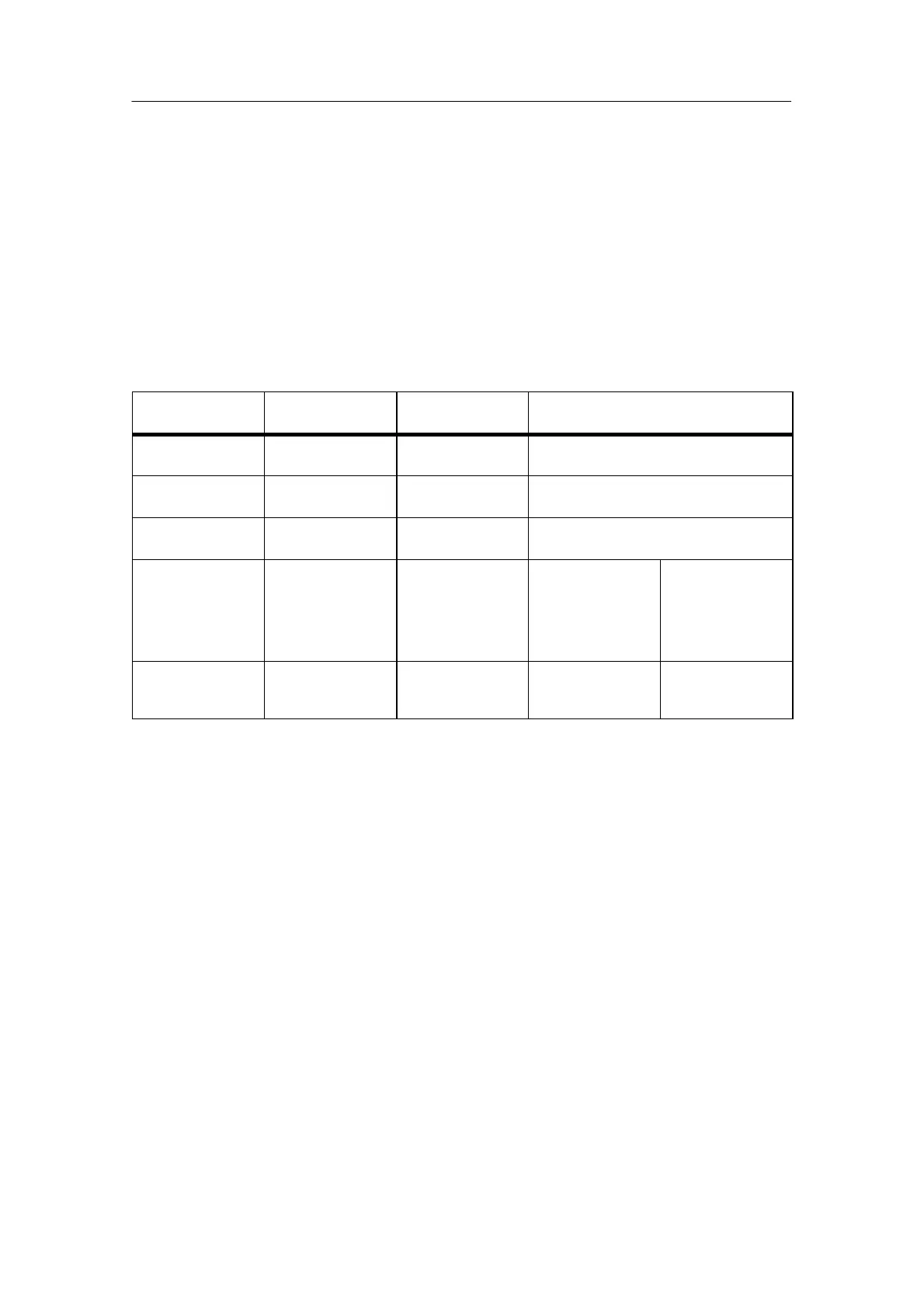

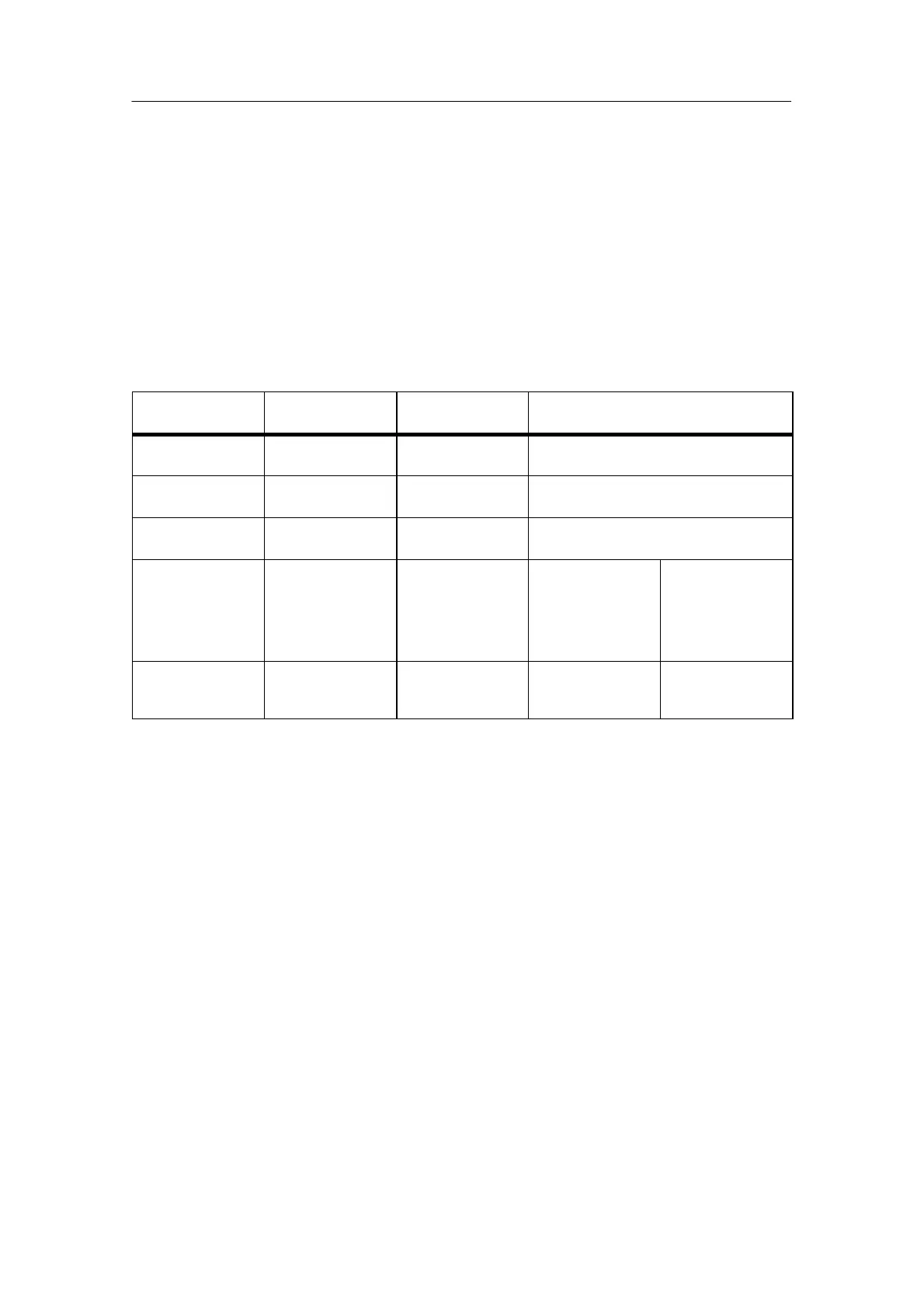

Table 1-2 Configuration variants of the S7-400

Selection criteria

Medium-sized

plant

Large plant Large plant with distributed signal

monitoring via PROFIBUS DP

Digital

input/outputs*

approx. 2000 approx. 11000 more than 11000

Analog

input/outputs*

approx. 1000 approx. 5500 more than 5500

Number of

modules

maximum 72 maximum 396 more than 396

Distance

(cable length)

3m

between first and

last rack

up to 605 m

between first and

last rack

up to 50 m

between 2 devices

up to 1000 m

with RS485

repeater

up to 23800 m

between 2 devices

The solution for

your task

Configuration with

4 racks and local

link

Configuration with

22 racks and

remote link

Communication via

MPI interface

Communication via

PROFIBUS DP

* The number only applies when only this type of module is used. This table is only intended to give you an

overview of the information. Mixed combinations are also possible, of course. The decision depends on

the type pf processes to be controlled and the local, on-site conditions.

Loading...

Loading...