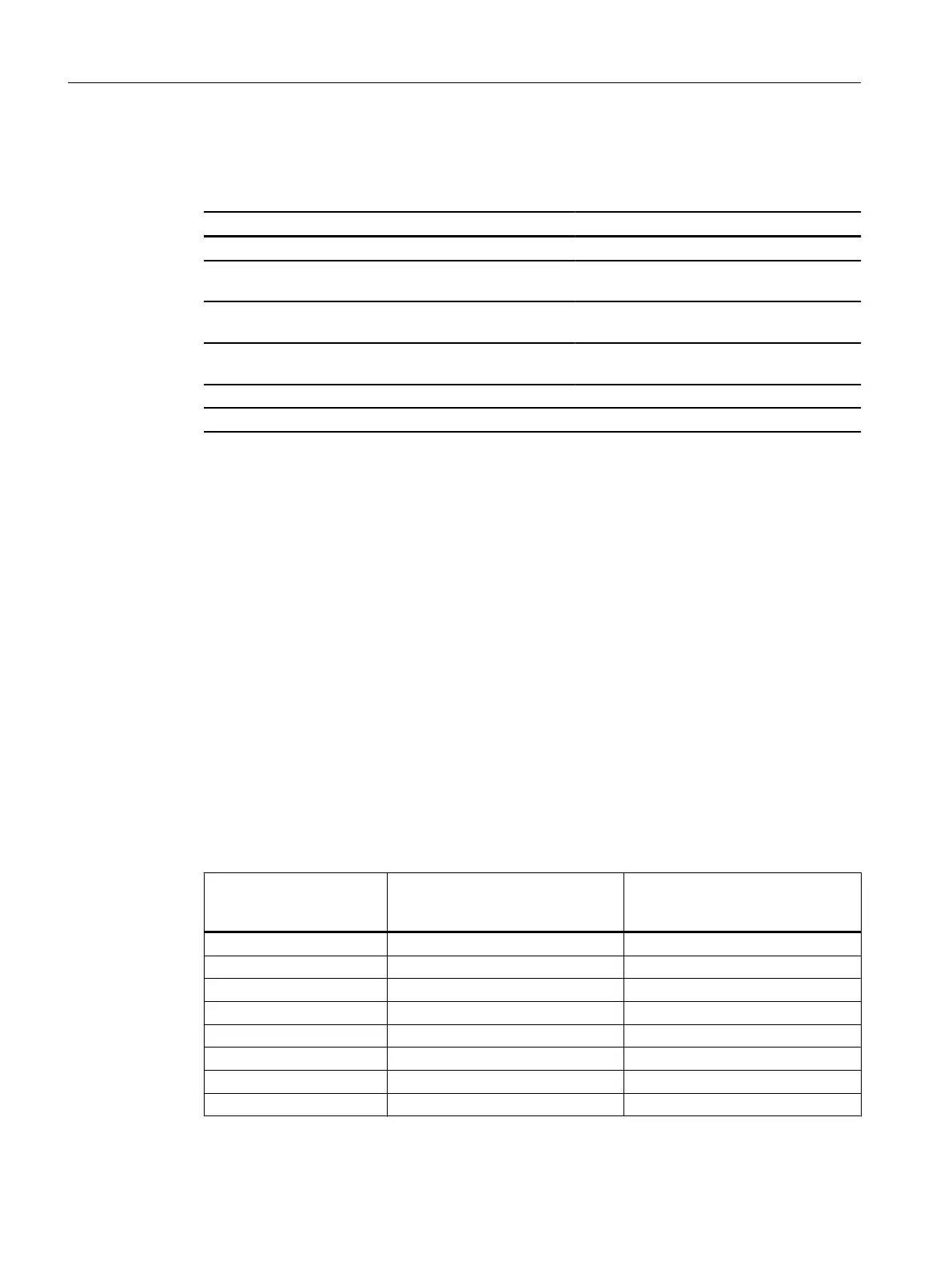

Maintenance intervals of the components

Table 8-1

Maintenance intervals

Component Review Replacement

Coolant Annually After ten years

Cooling hoses Regularly, at least every three

months

After six years

Fan Regularly, at least every three

months

After approximately 50,000 operating hours

Gaskets Regularly, at least every three

months

After six years

Filter See the notes in the cooling unit operating instructions

Pumps See the notes in the cooling unit operating instructions

8.2.3 Visual inspections

8.2.3.1

Tools required

You will need the following tools:

● Standard set of tools with screwdrivers, screw wrenches, socket wrenches, etc.

● Torque wrenches from 1.5 Nm up to 100 Nm

● 600 mm extension for socket wrenches

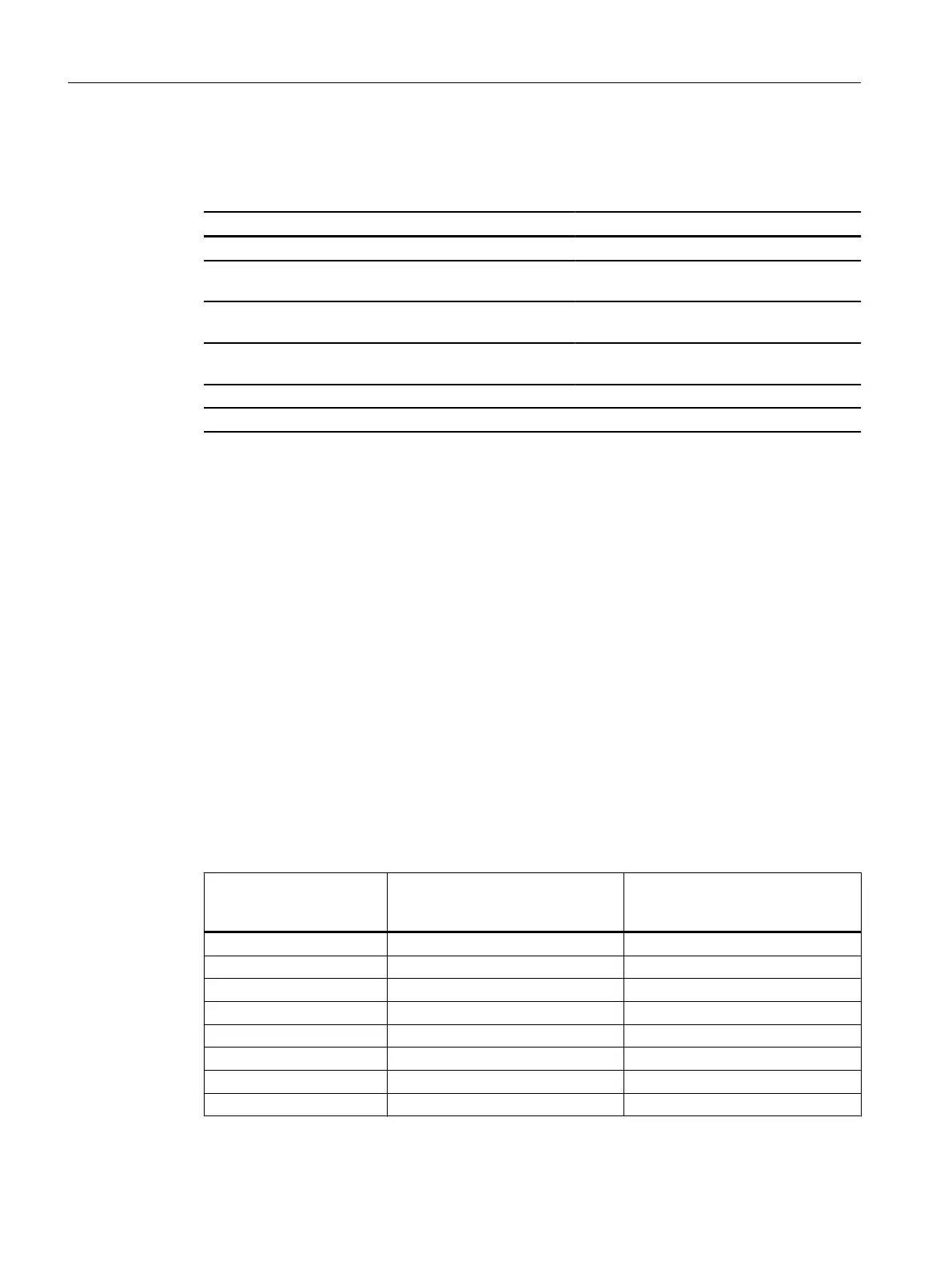

8.2.3.2 Torques

The following tightening torques apply when tightening current-conducting connections, e.g.

DC-link connections, motor connections, busbars, lugs and other connections (for example

ground connections, protective conductor connections, steel threaded connections/glands).

Table 8-2 Tightening torques for screw connections

Thread Ground connections, protective

conductor connections, steel threa‐

ded connections

Aluminum threaded connections,

plastic, busbars, lugs

M3 1.3 Nm 0.8 Nm

M4 3 Nm 1.8 Nm

M5 6 Nm 3 Nm

M6 10 Nm 6 Nm

M8 25 Nm 13 Nm

M10 50 Nm 25 Nm

M12 88 Nm 50 Nm

M16 215 Nm 115 Nm

Servicing

8.2 Preventive maintenance

Applications for Cabinet Modules, liquid cooled

108 Operating Instructions, 04/2015, A5E35974555A

Loading...

Loading...