3.5.13.3 The internal deionized water circuit

The internal water circuit is filled with deionized water (deionized, fully-desalinated water). The

conductivity of the cooling water must be ≤ 1 µS/cm in operation.

NOTICE

Material damage due to inadmissible additives in the deionized water

Inadmissible additives in the deionized water can cause the cooling system to fail. This could

damage the drive.

● Use only deionized water that corresponds to the specifications. The specification of the

deionized water can be found in the documentation for the re-cooling unit.

Deionized water requirements

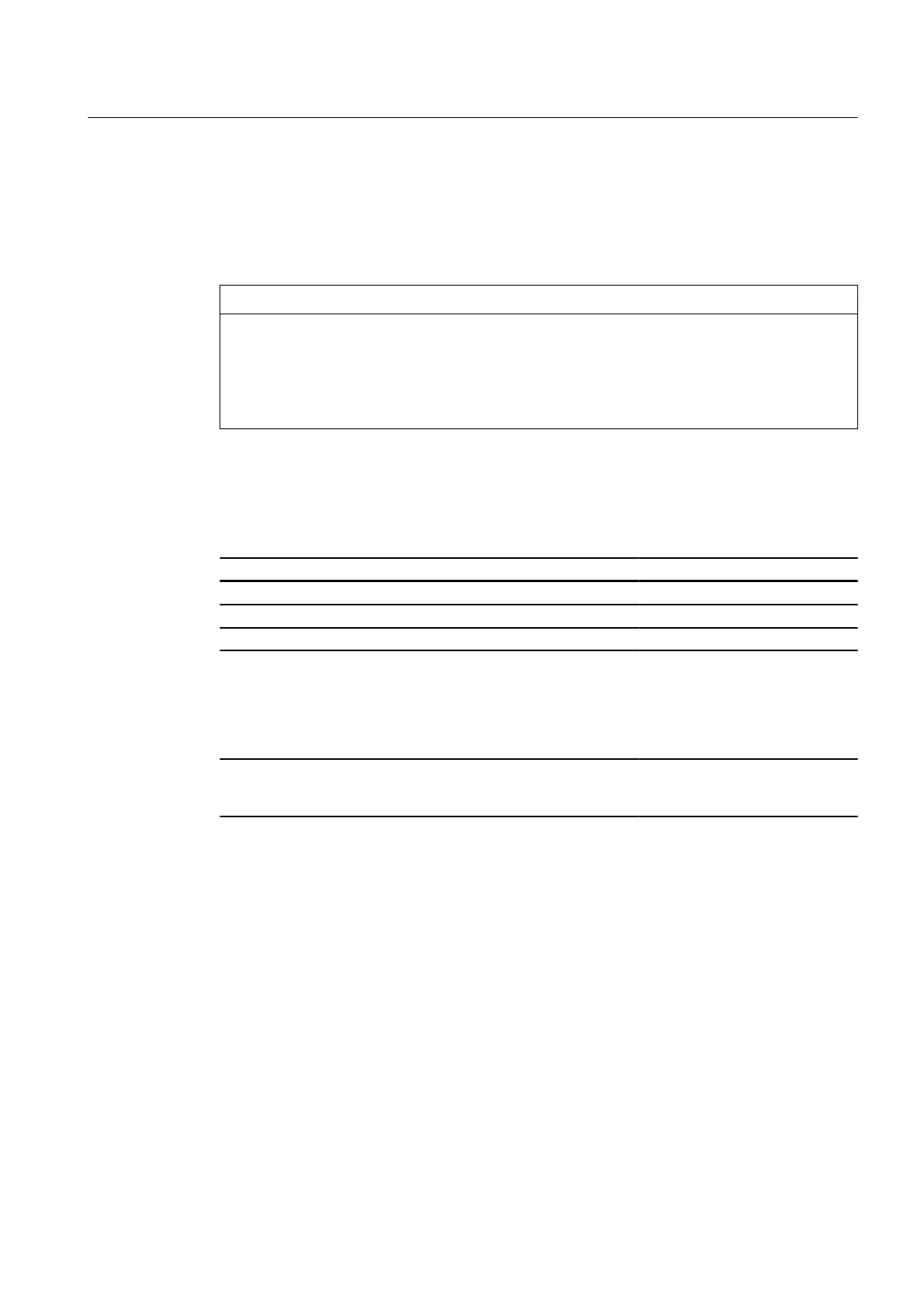

Table 3-1 Deionized water requirements

Value

Conductivity during filling < 10 μS/cm

Evaporation residue < 20 mg/l

pH value 5 to 9

● Content of metals in the hydrogen sulfide group (lead,

antimony, tin, bismuth, arsenic, copper, cadmium)

● Content of metals from the ammonium sulfide group (iron,

cobalt, nickel, chrome, manganese)

● Content of sulfur chloride and nitrogen compounds

Not detectable

Content of oxidizable, organic substances Max. a quantity equivalent to the

usage of 30 mg/l potassium per‐

manganate KMnO4

3.5.14 Customer terminal strips

The default setting and interfaces of the customer terminal strips can be found in the circuit

manual. For information about the position of the customer terminal strips within the cabinet,

see the layout diagrams.

Description

3.5 Description of the components

SINAMICS SM150 6SL3845-2NN41-8AD2

Operating Instructions Rev.201910281310 EXAMPLE 45

Loading...

Loading...