Technical Appendix

SINUMERIK 802S base line

6-11

Start-Up

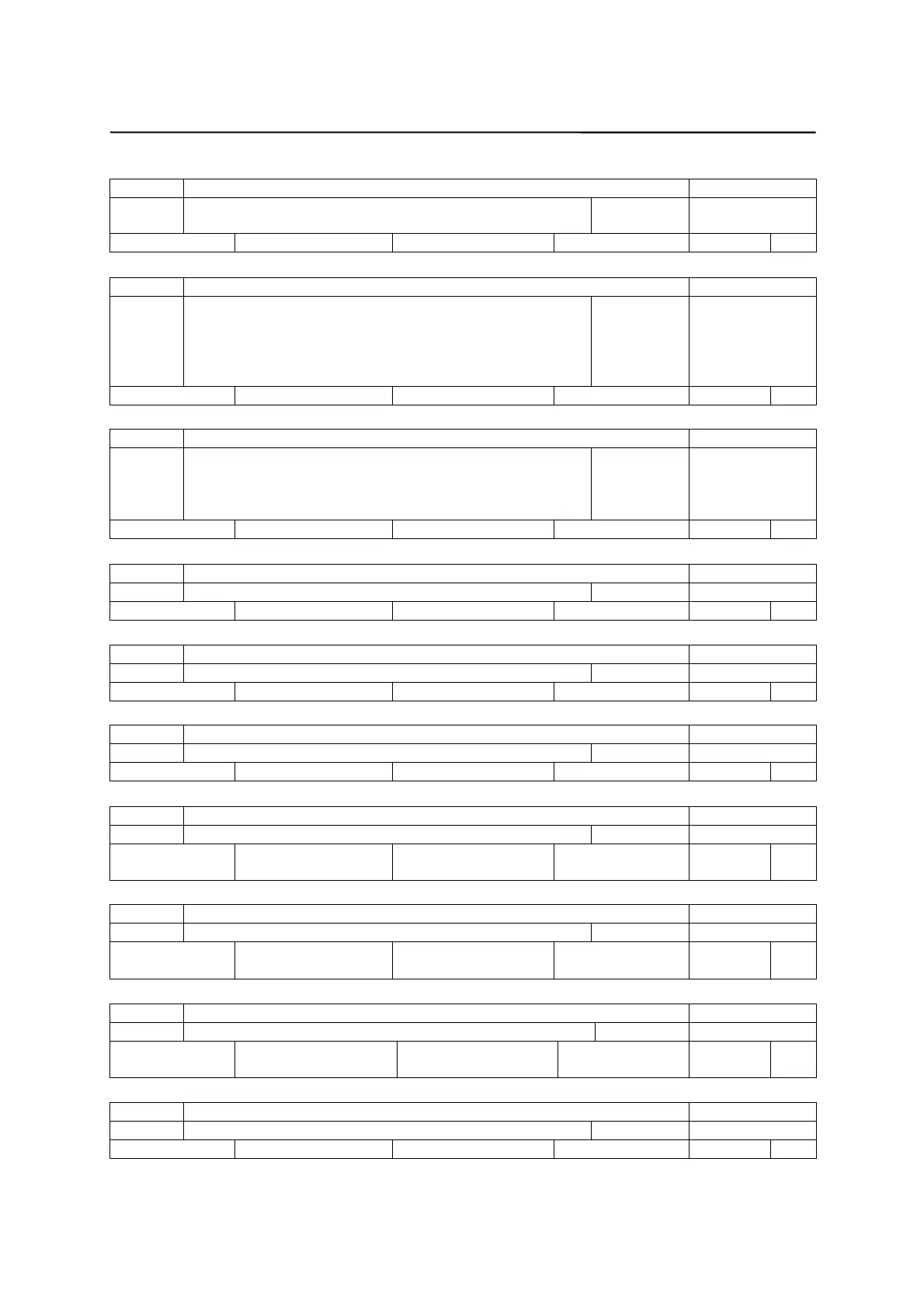

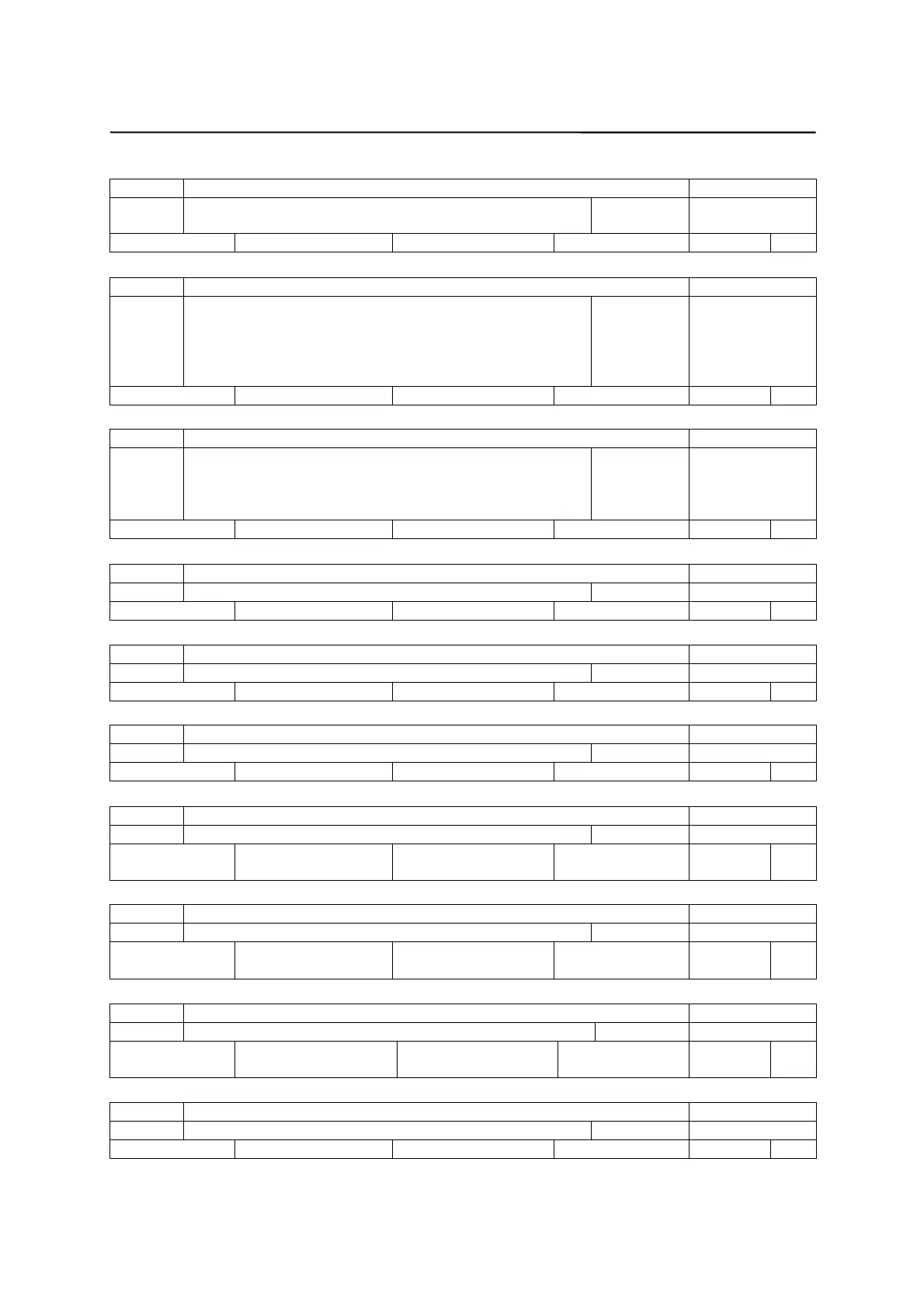

34100 REFP_SET_POS

mm,

deg.

Reference point value/irrelevant for distance–coded

system: 0 ... 3

RESET

_always 0., 0., 0., 0. – – DOUBLE 2/7

34110 REFP_CYCLE_NR

– Sequence of axes in channel–specific referencing

–1: No obligatory reference point for NC Start

0: No channel–specific reference–point approach

1–15: Sequence in channel–specific reference point

approach

RESET

_always 1 –1 31 DWORD 2/7

34200 ENC_REFP_MODE

– Type of position measuring system

0: No ref. point appr.; if an absolute encoder exists:

REFP_SET_POS accepted

1: Zero pulse (on encoder track)

POWER ON

_always 1 0 6 BYTE 2/7

35010 GEAR_STEP_CHANGE_ENABLE

– Gear change possible. Spindle has several gear steps POWER ON

_always 0 *** ***

BOOLEAN

2/7

35040 SPIND_ACTIVE_AFTER_RESET

– Own spindle reset POWER ON

_always 0 *** ***

BOOLEAN

2/7

35100 SPIND_VELO_LIMIT

rev/min Maximum spindle speed POWER ON

_always 10000 0.0 plus DOUBLE 2/7

35110 GEAR_STEP_MAX_VELO

rev/min Maximum speed for gear change (gear stage no.): 0..5 NEW CONF

_always 500, 500, 1000,

2000, 4000, 8000

0.0 plus DOUBLE 2/7

35120 GEAR_STEP_MIN_VELO

rev/min Minimum speed for gear change (gear stage no.): 0..5 NEW CONF

_always 50, 50, 400, 800,

1500, 3000

0.0 plus DOUBLE 2/7

35130 GEAR_STEP_MAX_VELO_LIMIT

rev/min Maximum speed of gear stage (gear stage no.): 0...5 NEW CONF

_always 500, 500, 1000, 2000,

4000, 8000

0.0 plus DOUBLE 2/7

35140 GEAR_STEP_MIN_VELO_LIMIT

rev/min Minimum speed of gearsetp (gear stage no.): 0...5 NEW CONF

_always 5, 5,10, 20, 40, 80 0.0 plus DOUBLE 2/7

Loading...

Loading...