Start-Up

4-36

SINUMERIK 802S base line

Start-Up

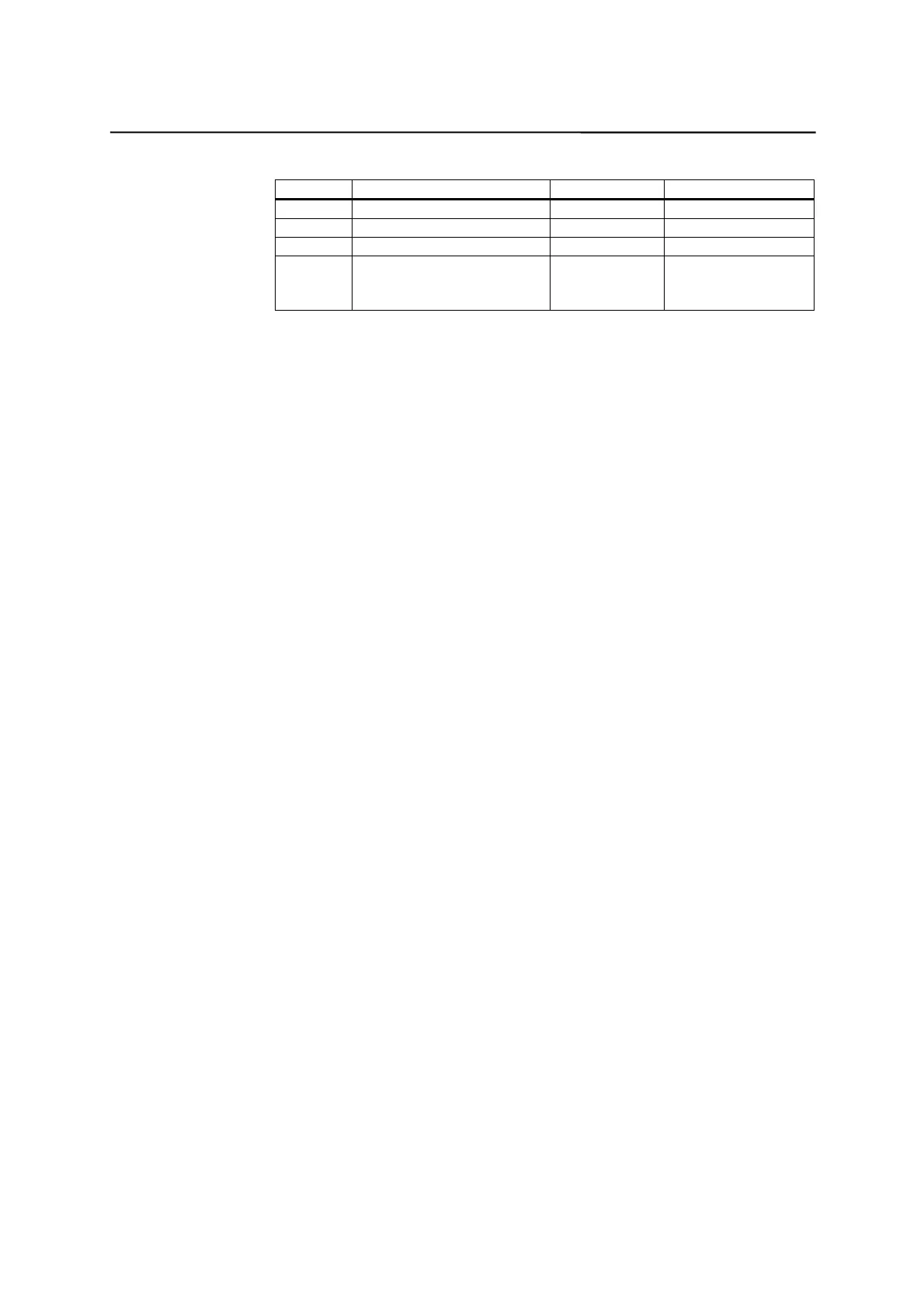

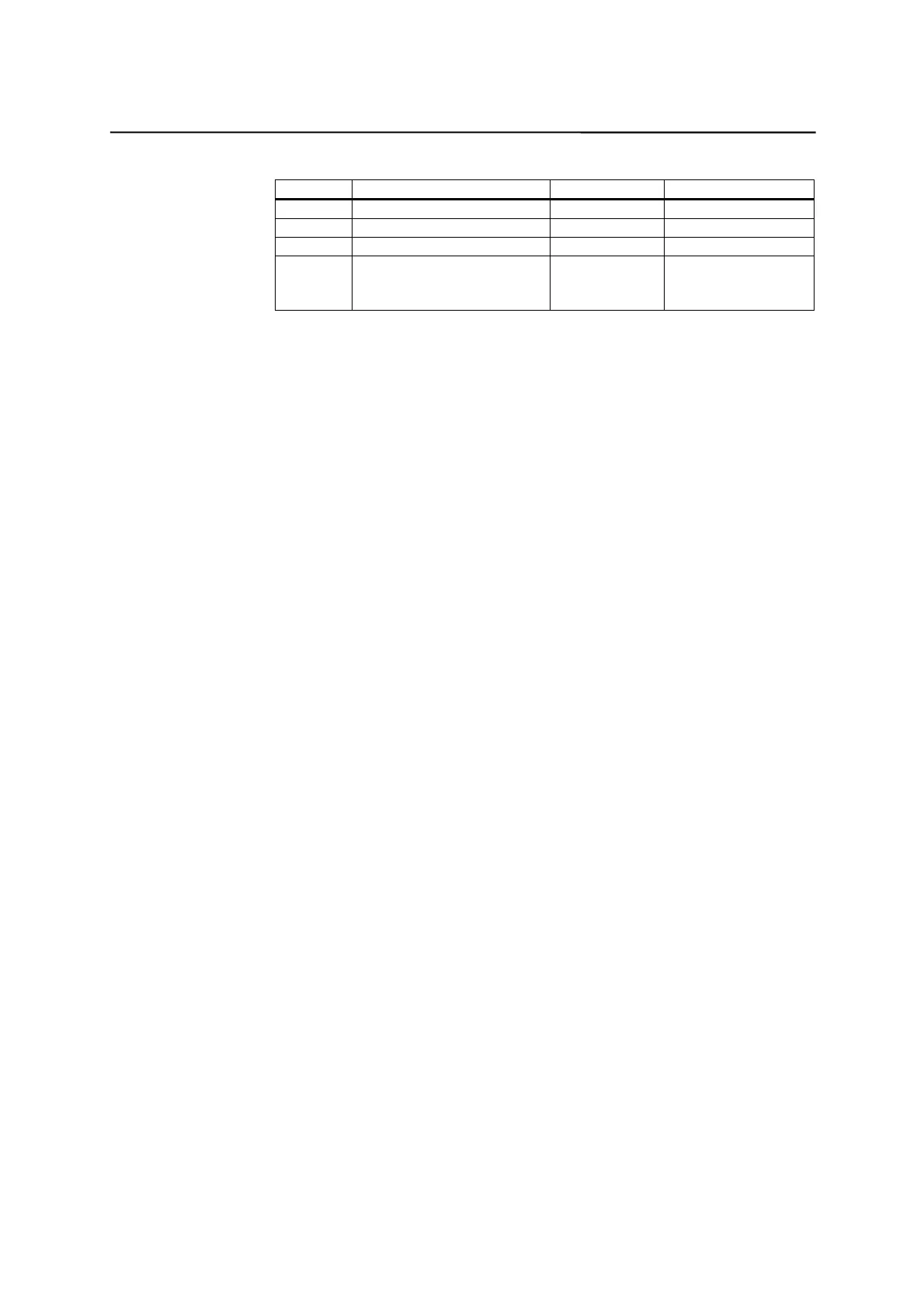

To solve monitoring problems, set the following machine data:

Number Description Default Value Setting or Remark

36000 Exact positioning coarse 0.04 0.5

36010 Exact positioning fine 0.01 0.1

36020 Delay exact positioning fine 1.0 4

36060 Maximum

velocity/speed ”axis/spindle

stopped”

5.0 20

Parameterization example

Stepper motor: 10,000 [pulses per motor revolution]

Load gear: 1:1

Leadscrew pitch: 10 mm

Motor speed: 1,200 rpm

MD 30130 =2

MD 30240 =3

MD 31400 =10,000

MD 32260 =1,200 rpm

MD 32000 =12,000 mm/min

Stepper motor frequency

The parameterization is carried out using the machine data, which have

already been mentioned, after POWER–ON.

The resulting stepper motor frequency is displayed with machine data MD

31350.

Motor speed [rpm] • steps per stepper motor revolution

MD 31350 [Hz]= ------------------------------------------------------------------------------

60 [s]

This frequency must correspond to MD 32000.

Supplementary conditions

Servo gain

The default setting of the servo gain when controlling stepper motors without

measuring system is K

v

= 2.5 (MD: 32200, limit approx. 2.5).

Max. stepper motor frequency

The max. permissible stepper motor frequency is 500 kHz.

PLC interface signals when using a stepper motor in the controlled mode

When using a stepper motor as an axis (spindle), the PLC interface signals

have to be used as follows:

The “Servo enable” signal provided via the NC will not be used to turn off the

drive (“Drive Enable” is always active). This pertains to the following signals:

Loading...

Loading...