Start-Up

4-48

SINUMERIK 802S base line

Start-Up

Gear stage 2

360 degrees MD 31080 MD 31050

Internal resolution = ------------------------- x -------------------------- x ------------------- x 1000incr/deg

MD 31020 x 4 MD 31070 MD 31060

360 1 1

Internal resolution = ----------------- x ------------- x ------------ x 1000pulses/deg = 43.945

4 x 2048 1 1

One encoder increment corresponds to 43.945 internal increments. One

encoder increment corresponds to 0.043945 degrees (minimum positioning

step).

Spindle setpoint adaptation

To adapt the spindle setpoint and its gear stage, the following axis MD and

interface signals are relevant:

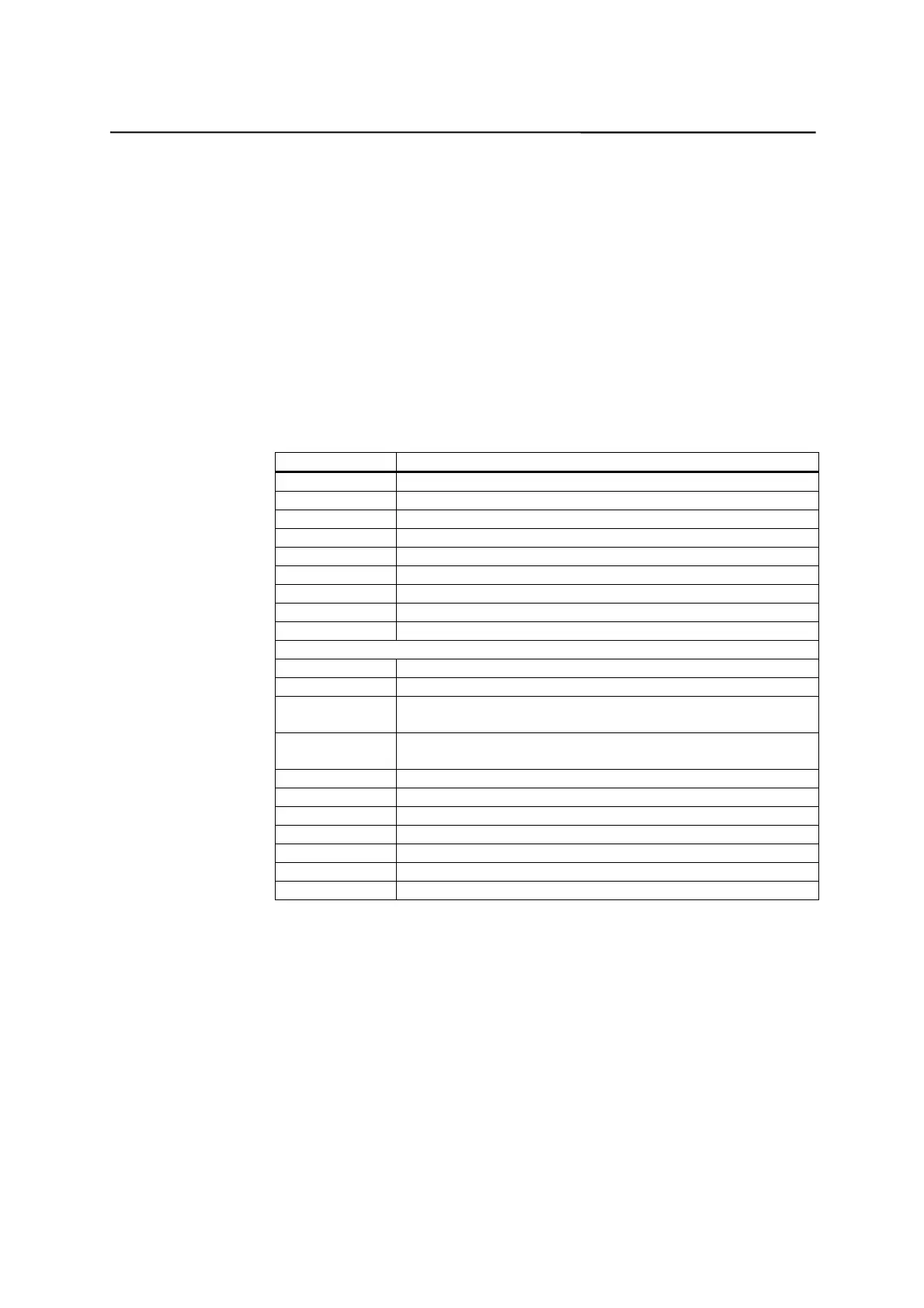

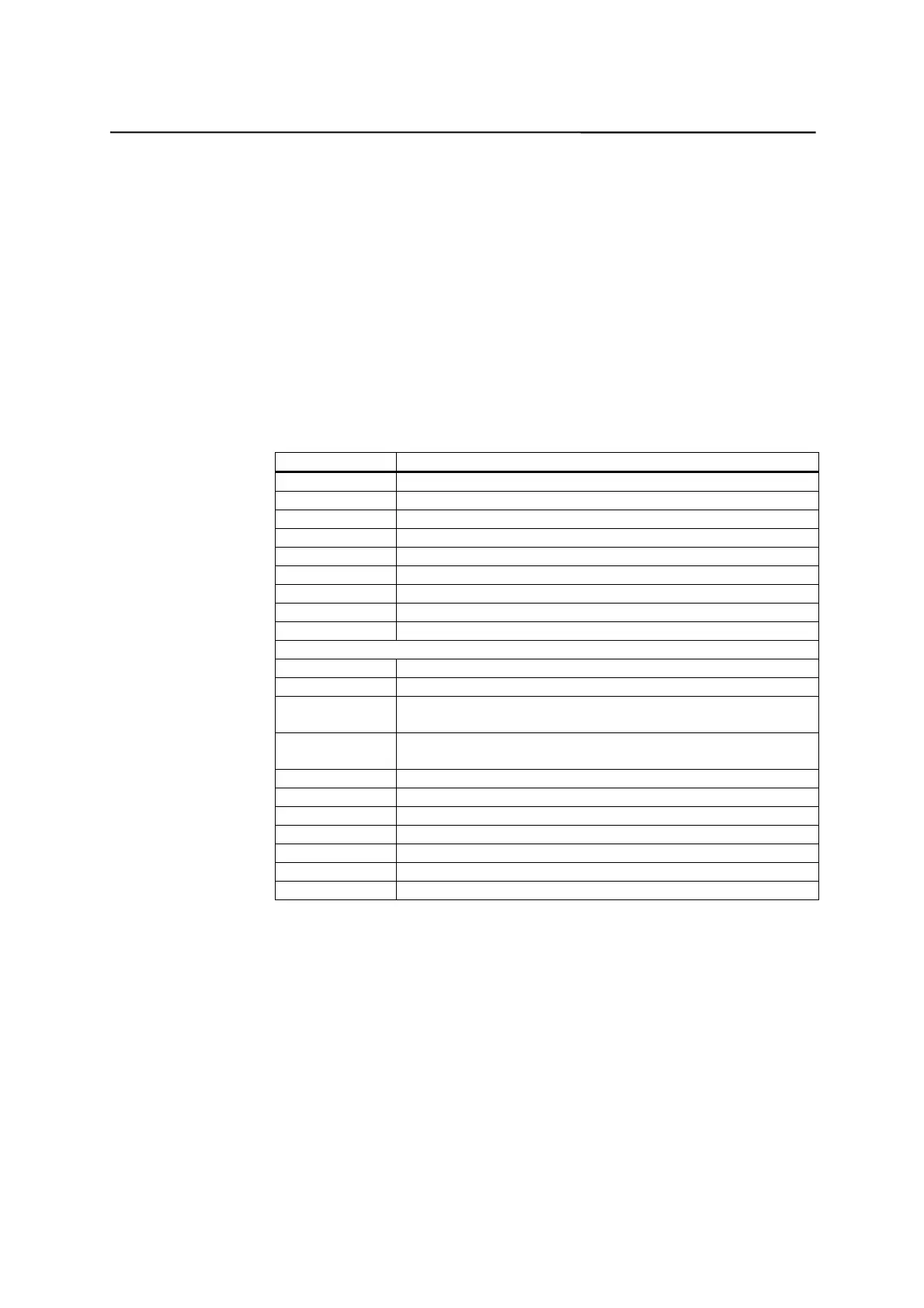

Number Description

32010 Rapid traverse in jog mode

32020 Jog axis velocity

35110 Maximum speed for gear change (gear stage no.): 0..5

35120 Minimum speed for gear change (gear stage no.): 0..5

35130 Maximum speed of gear stage (gear stage no.): 0...5

35140 Minimum speed of gearstage (gear stage no.): 0...5

35200 Acceleration in speed control mode [gear stage no.]: 0...5

31060 Numerator load gearbox (control parameter set no.): 0...5

31050 Denominator load gearbox (control parameter no.): 0...5

Interface signals

“Switch gear“ 39032000 bit 3

“Actual gearstage” 38032000 bits 0 through 2

“No speed monitoring when switching the gear”

38032000 bit 6

“Gear has been switched”

38032000 bit 3

“Setpoint gear stage” 39032000 bits 0 through 2

“Positioning mode” 39032002 bit 5

“Reciprocation by PLC”38032002 bit 4

“Reciprocation mode” 39032002 bit 6

“Control mode” 39032002 bit 7

“Traversing minus” 39030004 bit 6

“Traversing plus” 39030004 bit 7

The default settings of these MD has been selected such that spindle motion is

possible both in the simulation mode (MD 30130=0) and with drive (MD

30130=1).

Reciprocation mode for gear change

The reciprocation mode of the spindle is intended to facilitate the gear change.

For reciprocation mode, the following axis MD and interface signals are

relevant:

Loading...

Loading...