Start-Up

SINUMERIK 802S base line

4-47

Start-Up

Matching encoder to spindle

Machine data for encoder adjustment

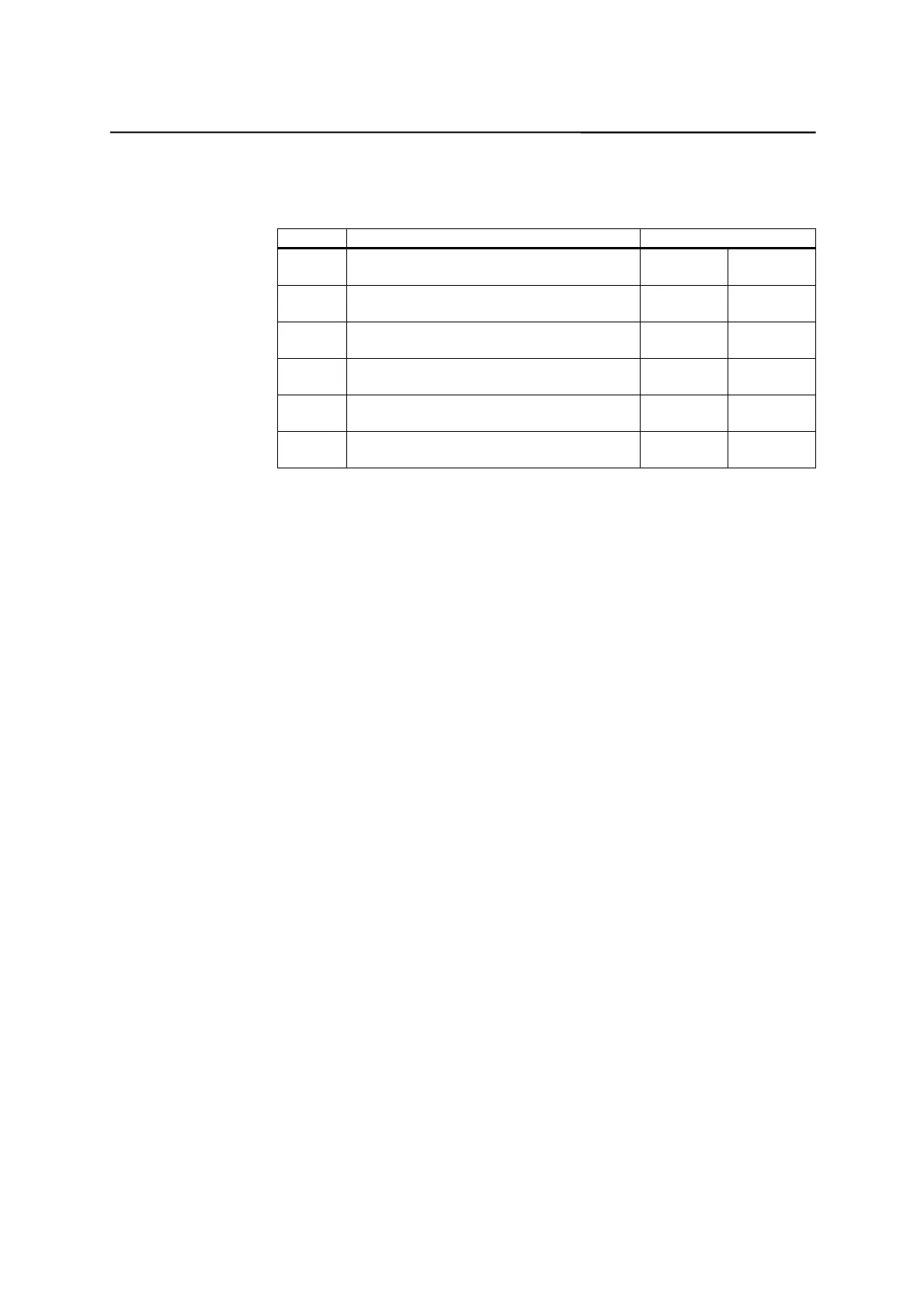

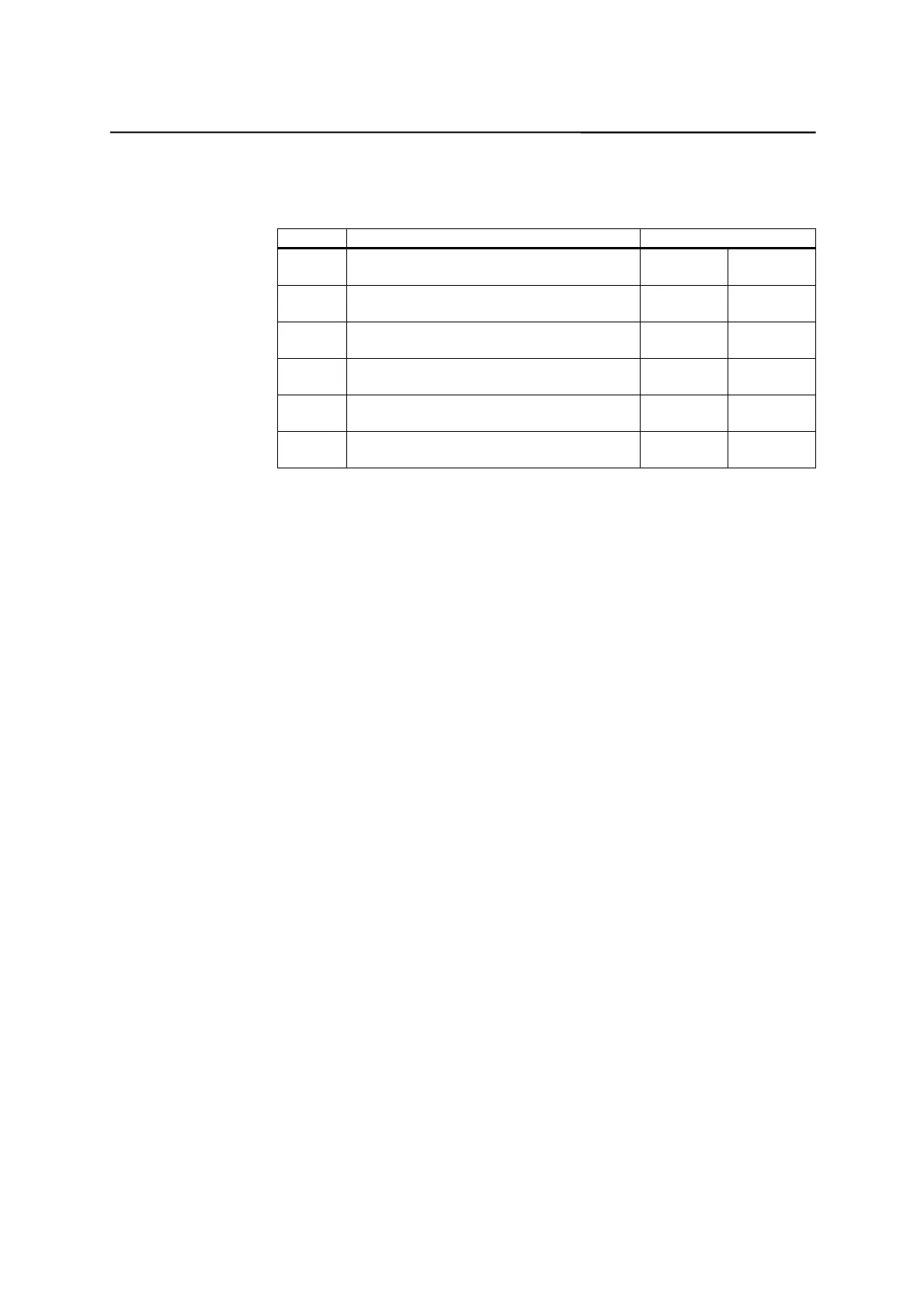

Number Description Spindle

31040 Encoder mounted directly to the machine

(encoder no.)

01

31020 Encoder markings per revolution

(encoder no.)

Incr. /rev. Incr. /rev.

31080 Numerator resolver gearbox

(encoder no.)

Motor revs Load rev.

31070 Denominator resolver gearbox

(encoder no.)

Enc. revs Enc. revs

31060 Numerator load gearbox

(control parameter set no.): 0...5

Motor revs Motor revs

31050 Denominator load gearbox

(control parameter no.): 0...5

Load revs Load revs

Example 1 for encoder matching:

Spindle with rotary encoder (500 pulses) mounted directly on the motor. The

internal multiplication factor is 4. The internal computational resolution

amounts to 1,000 increments per degree.

360 degrees MD 31080

Internal resolution = ------------------------- x ----------------------- x 1000

MD 31020 x 4 MD 31070

360 x 1 x 1000

Internal resolution = ---------------------------- = 180

500 x 4 x 1

One encoder increment corresponds to 180 internal increments. One encoder

increment corresponds to 0.18 degrees (minimum positioning step).

Example 2 for encoder matching:

Spindle with rotary encoder on motor (2,048 pulses), internal multiplication

= 4, 2 speed stages exist:

Gear stage 1: Motor/spindle = 2.5/1

Gear stage 2: Motor/spindle = 1/1

Gear stage 1

360 degrees MD 31080 MD 31050

Internal resolution = ------------------------- x -------------------------- x ------------------- x 1000incr/deg

MD 31020 x 4 MD 31070 MD 31060

360 1 1

Internal resolution = ----------------- x ------------- x ------------ x 1000pulses/deg = 17.5781

4 x 2048 1 2.5

One encoder increment corresponds to 17.5781 internal increments. One

encoder increment corresponds to 0.0175781 degrees (minimum positioning

step).

Loading...

Loading...