Cycles

2.5 Turning cycles

Turning Part 2: Programming (Siemens instructions)

166 Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

No plausibility check is carried out for the programmed values. In other words: If all three

parameters are assigned values, all these finishing allowances are taken into account by the

cycle. It is, however, reasonable to decide either on the one or other form of definition of a

finishing allowance.

Roughing is always carried out up to these finishing allowances. The resulting residual

corner is also removed parallel to the contour after each paraxial roughing process

immediately so that no additional residual corner cut is required after completion of roughing.

If no finishing allowances are programmed, stock is removed when roughing up to the final

contour.

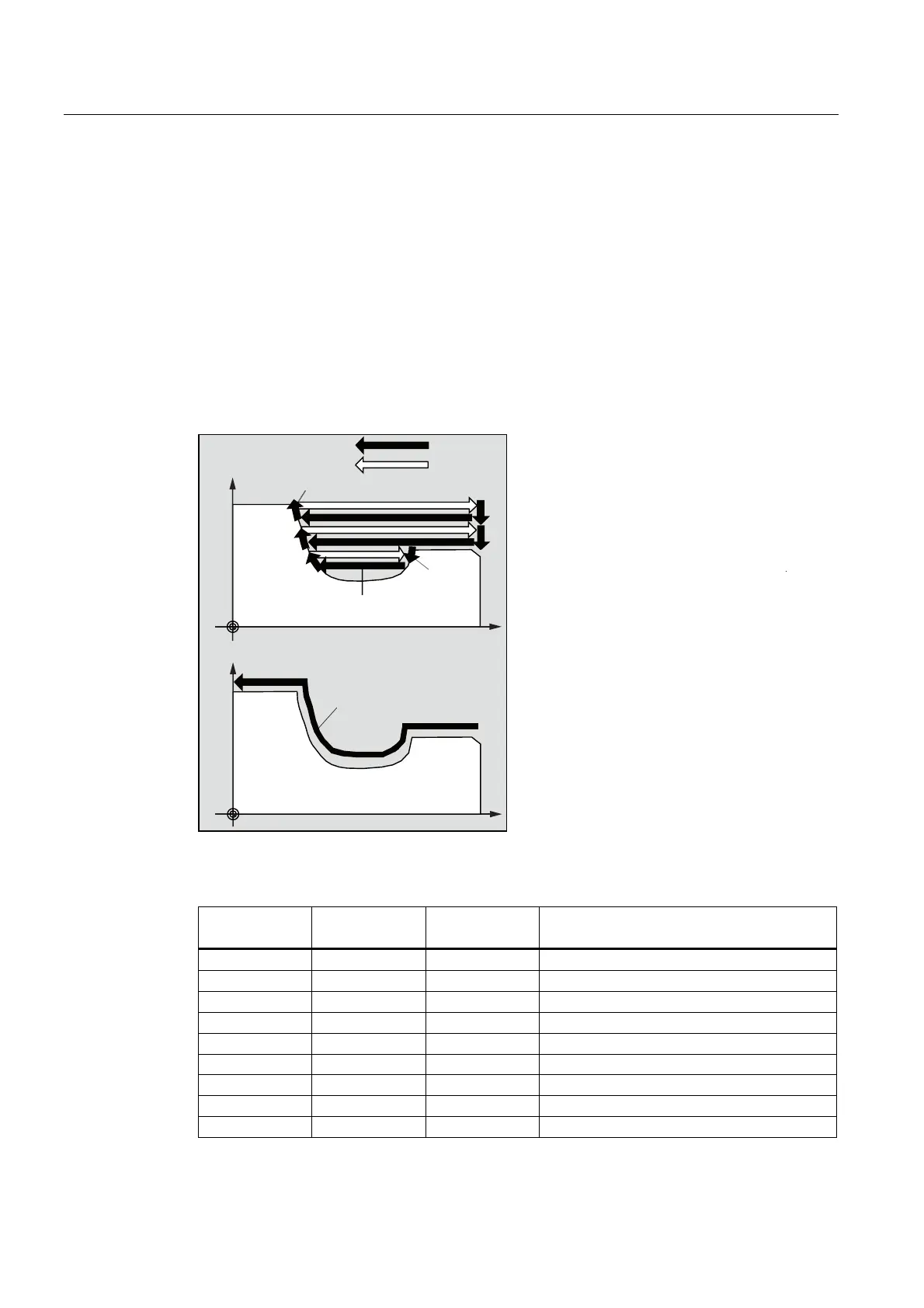

FF1, FF2 and FF3 (feedrate)

It is possible to specify different feedrates for the individual machining steps, as shown in

Figure NO TAG.

)LQLVKLQJ

=

;

=

;

))

***

*

5RXJKLQJ

))

))

))

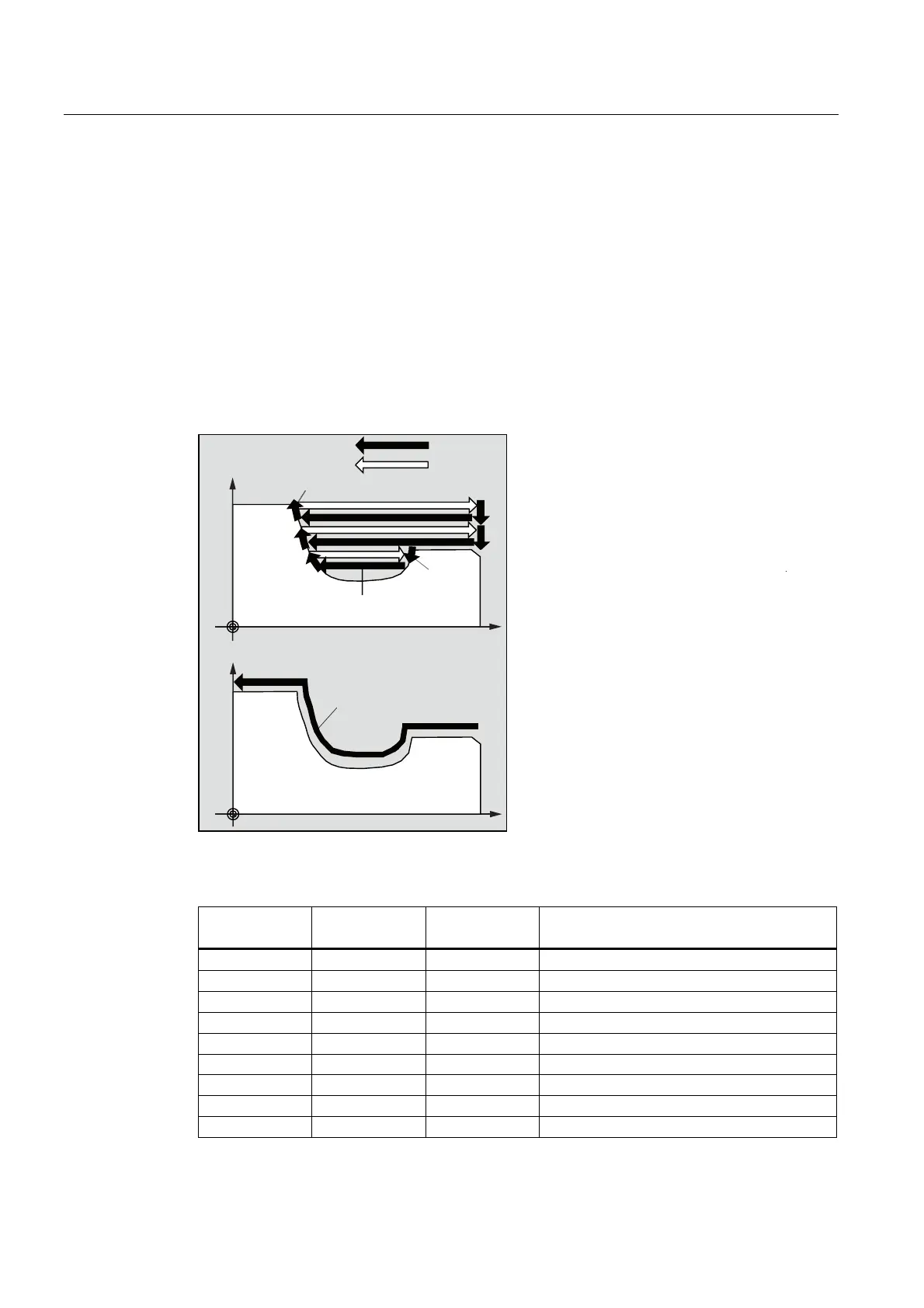

VARI (machining type)

The machining type can be found in the table below.

Value Longitudinal/fac

e

Ext./int. Roughing/finishing/complete

1 L O Roughing

2 P O Roughing

3 L I Roughing

4 P I Roughing

5 L O Finishing

6 P O Finishing

7 L I Finishing

8 P I Finishing

9 L O Complete machining

Loading...

Loading...