Programming principles

1.4 Spindle movements

Turning Part 2: Programming (Siemens instructions)

62 Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

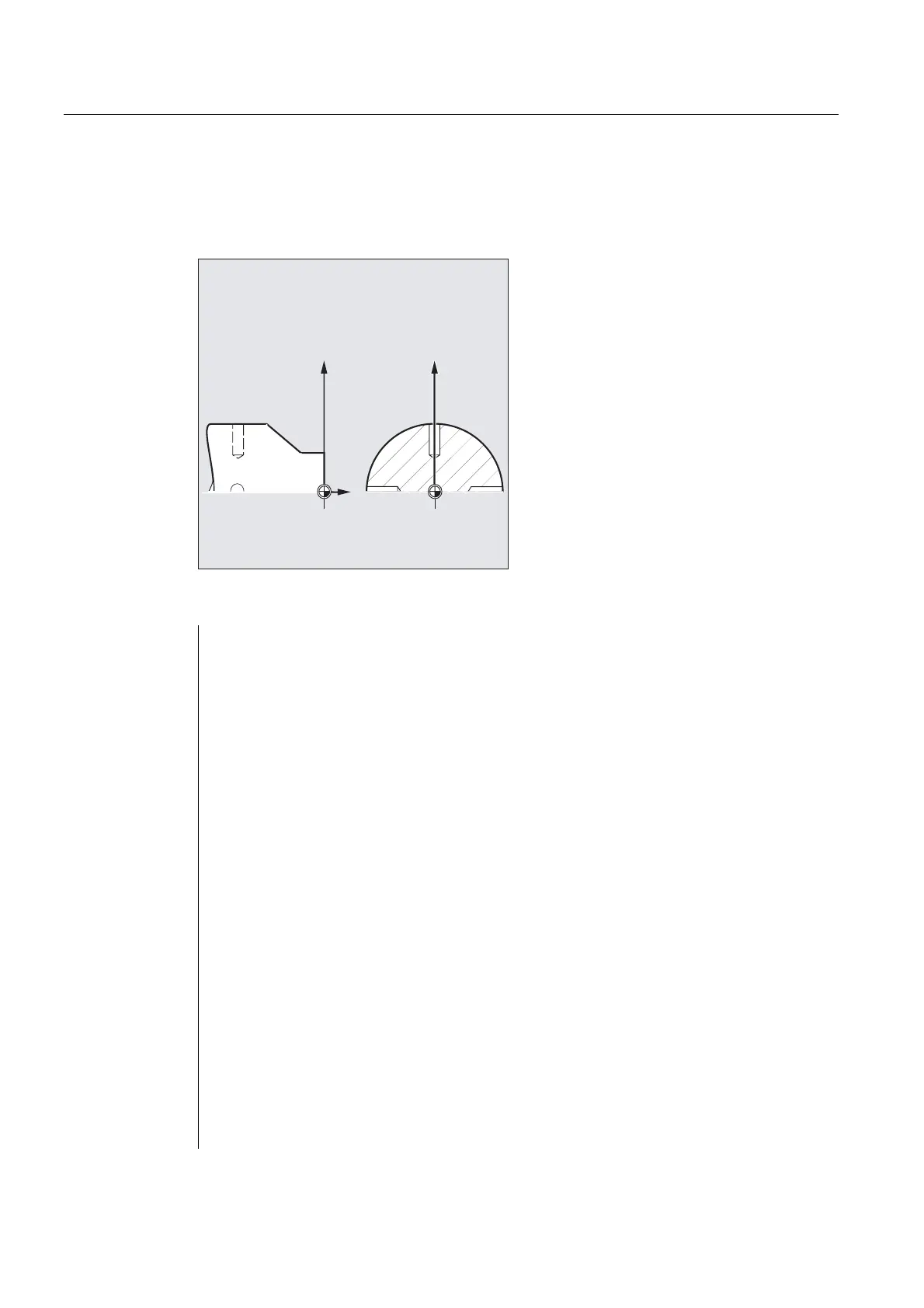

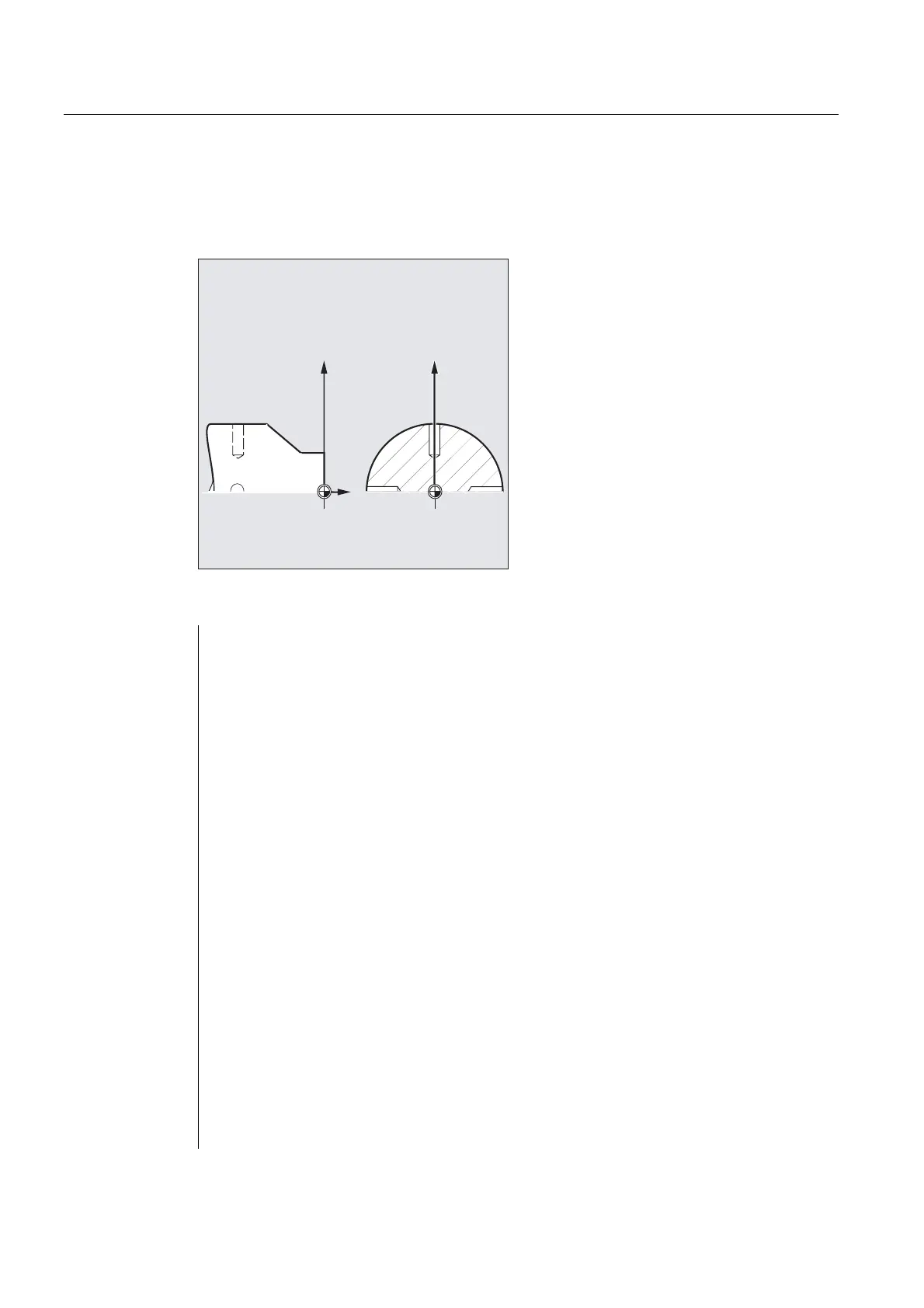

Example 3: Drill cross holes in turned part

Cross holes are to be drilled in this turned part. The running spindle is stopped at zero

degrees and then successively turned through 90°, stopped and so on.

=

; ;

Figure 1-28 Rotating part, spindle

G0 X100 Z100

N110 S2=1000 M2=3 ; Switch on cross drilling attachment.

N120 SPOSA=DC(0) ; Set main spindle to 0° immediately,

the program will advance to the next block straight

away.

N125 G0 X34 Z-35 ; Switch on the drill while the spindle is taking up

position.

N130 WAITS ; Wait for the main spindle to reach its position.

N135 G1 G94 X10 F250 ; Feedrate in mm/min (G96 is suitable only for the

multi-edge turning tool and synchronous spindle, but

not for power tools on the cross slide.)

N140G0 X34

N145 SPOS=IC(90) ; The spindle is positioned through 90° with read halt

in a positive direction.

N150 G1 X10

N155 G0 X34

N160 SPOS=AC(180) ; The spindle is positioned at 180° relative to the

spindle zero point.

N165 G1 X10

N170 G0 X34

N175 SPOS=IC(90) ; The spindle turns in a positive direction through 90°

from the absolute 180° position, ending up in the

absolute 270° position.

N180 G1 X10

N185 G0 X50

M30

Loading...

Loading...