Programming principles

1.6 Tool and tool offset

Turning Part 2: Programming (Siemens instructions)

74 Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

The compensation is retracted with the first programmed traversing of the associated length

compensation axis.

A tool radius compensation must also be activated by G41/G42.

Programming example

Tool change:

N10 T1 ; Tool 1 is activated with the associated D1

N20 G0 X100 ; The length offset compensation is overlaid here

N30 Z100

N40 T4 D2 ; Load tool 4, D2 from T4 is active

N50 X50 Z50

N60 G0 Z62

N70 D1 ; D1 for tool 4 active, only cutting edge changed

N80 M30

Contents of a compensation memory

● Geometrical dimensions: Length, radius.

They consist of several components (geometry, wear). The control takes into account the

components to obtain a resulting dimension (e.g. overall length 1, total radius). The

respective overall dimension becomes active when the offset memory is activated.

The way in which these values are computed in the axes is determined by the tool type

and the current plane G17, G18, G19.

● Tool type

The tool type (drill or turning tool) determines which geometry data are required and how

they will be calculated.

● Cutting edge position

For the "turning tool" tool type, you must also enter the cutting edge position.

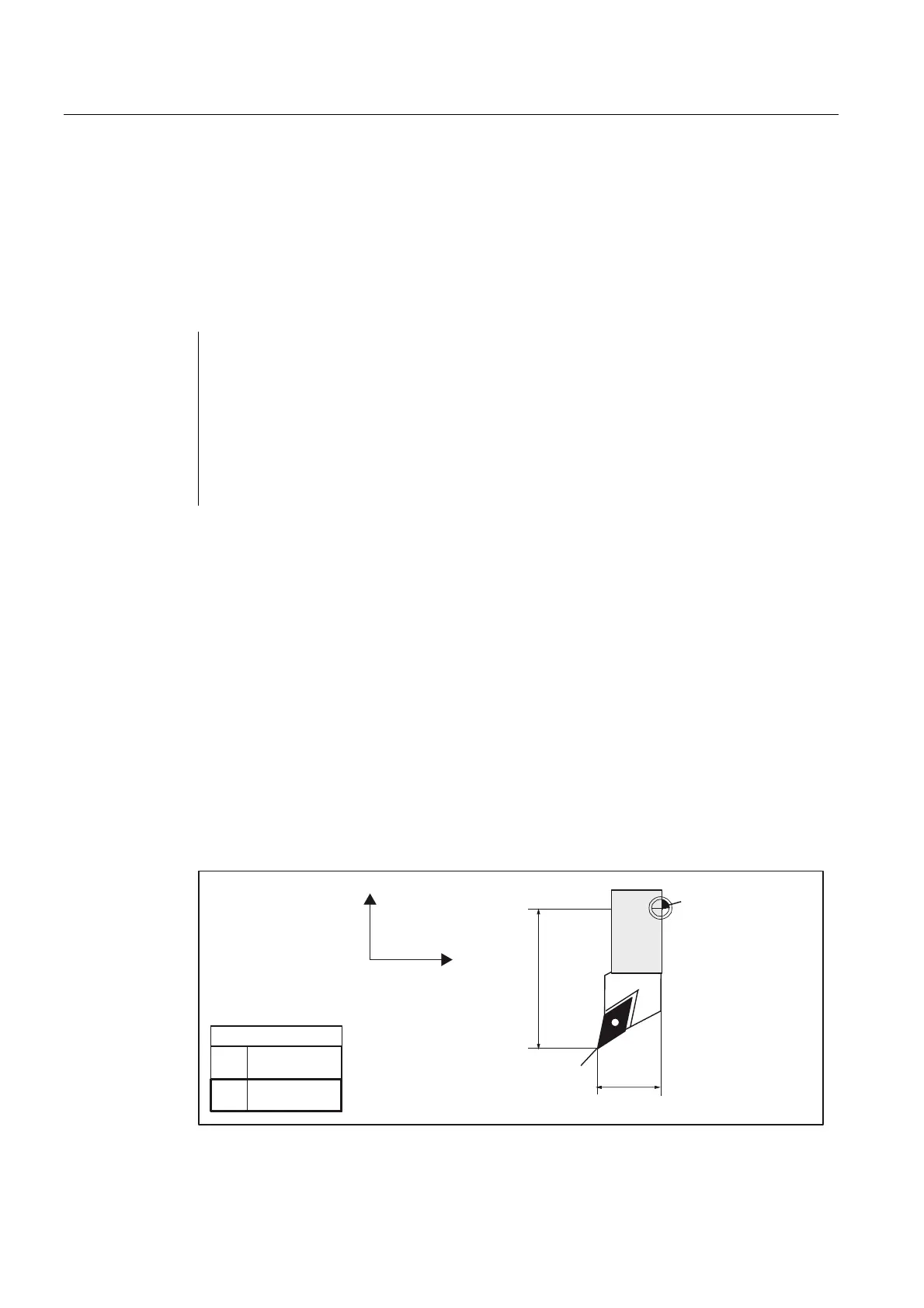

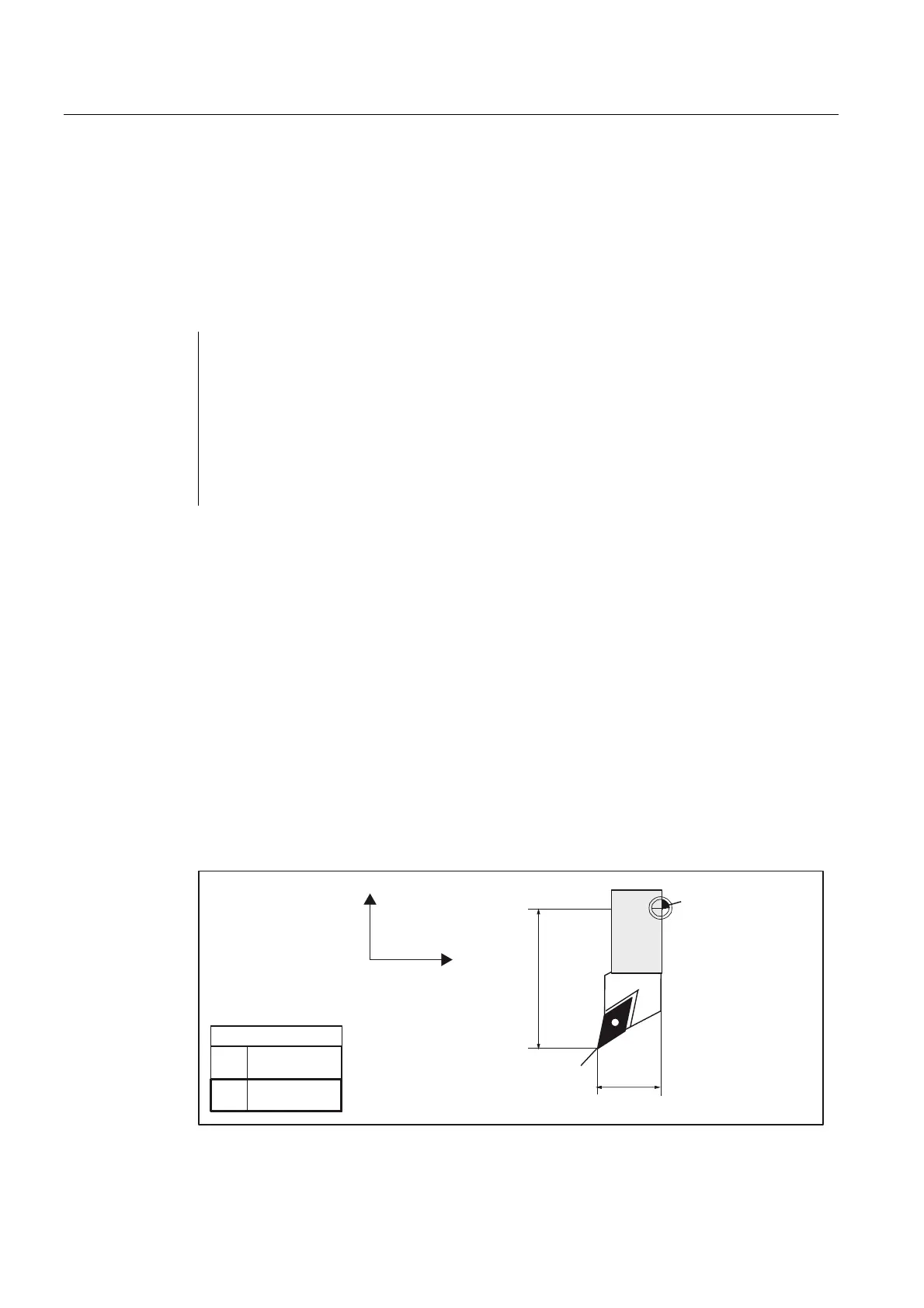

The following figures provide information on the required tool parameters for the respective

tool type.

7XUQLQJWRRO

;

=

)WRROKROGHU

UHIHUHQFHSRLQW

/HQJWK

;

/HQJWK

=

7RROWLS3

FXWWLQJHGJH

(IIHFW

*/HQJWKLQ;

/HQJWKLQ=

Figure 1-37 Tool length compensation values for turning tools

Loading...

Loading...