5 Measuring Cycles for Milling Machines and Machining Centres 07.90

5.4.3 L978 Paraxial multipoint measurement

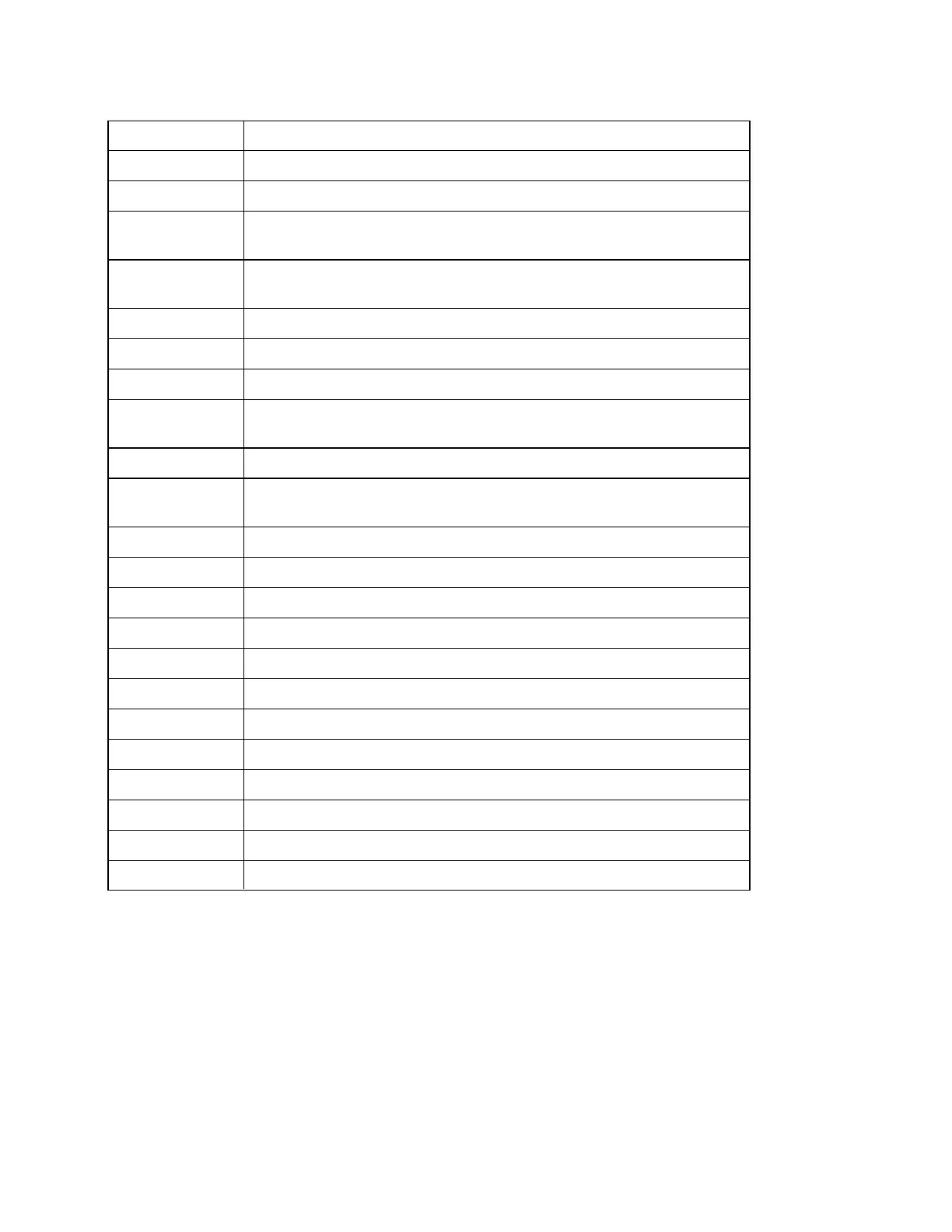

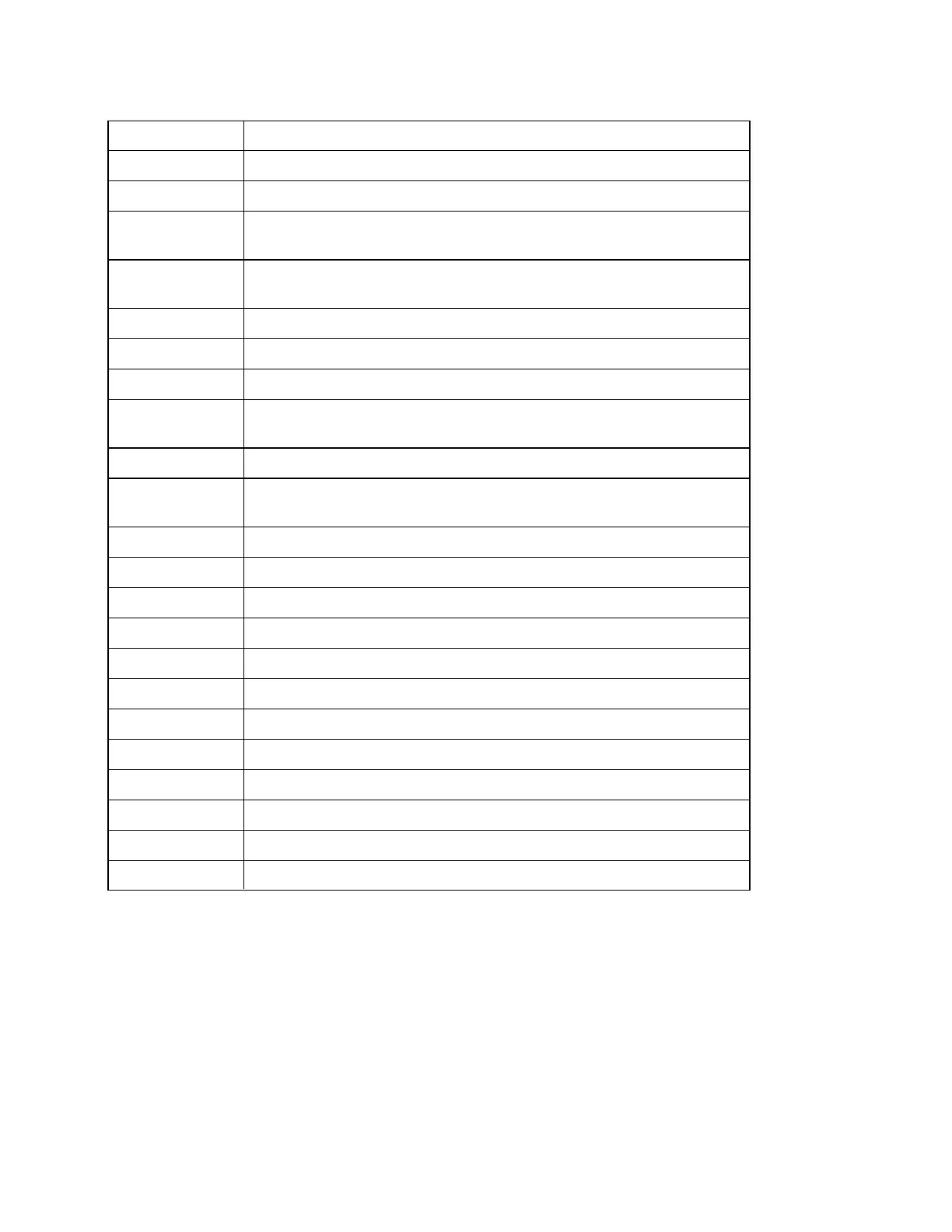

The following parameters must be defined prior to call:

Parameters Description

R08 Extended T address (see Section 2.2)

R09 T number (tool number) (see Section 2.2)

R10 = 0

> 0

No automatic tool offset

Automatic tool offset (see Section 2.2)

R11 = 0

> 0

Without empirical value

Empirical value memory number (see Section 2.3)

R13 = 0...359,5 Compensation angle position for monodirectional probe (see Section 2.5)

R19 Infeed offset axis (incremental)

R22 Probe number (see Section 2.6)

R23 = 2

= 12

Paraxial multipoint measurement

Paraxial multipoint measurement with differential measurement

R24 Number of measuring points

R25

R25 = 0

Variable measuring speed in mm/min

Standard cycle value

R26 = 0...359.5 Start angle (with differential measurement only)

R27 = 1...R

max

Number of measurement at same location (typically 1..3)

R28 = 1...R

max

Multiplication factor for measurement path ”2a”

R29 = 1...R

max

Weighting factor k for averaging (typically 1...3)

R30 = 102..302 Number of offset axis (see Section 2.12)

R33 Zero offset range

R34 Compensation range with averaging

R36 Safe area

R37 Dimensional difference check

R40 Upper tolerance limit (according to drawing)

R41 Lower tolerance limit (according to drawing)

R42 Set value (according to drawing)

See Section 10.2 for result display parameters.

5–74 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB70

SINUMERIK 840/850/880 (BN)

Loading...

Loading...