08.96 4 Measuring Cycles for Turning Machines

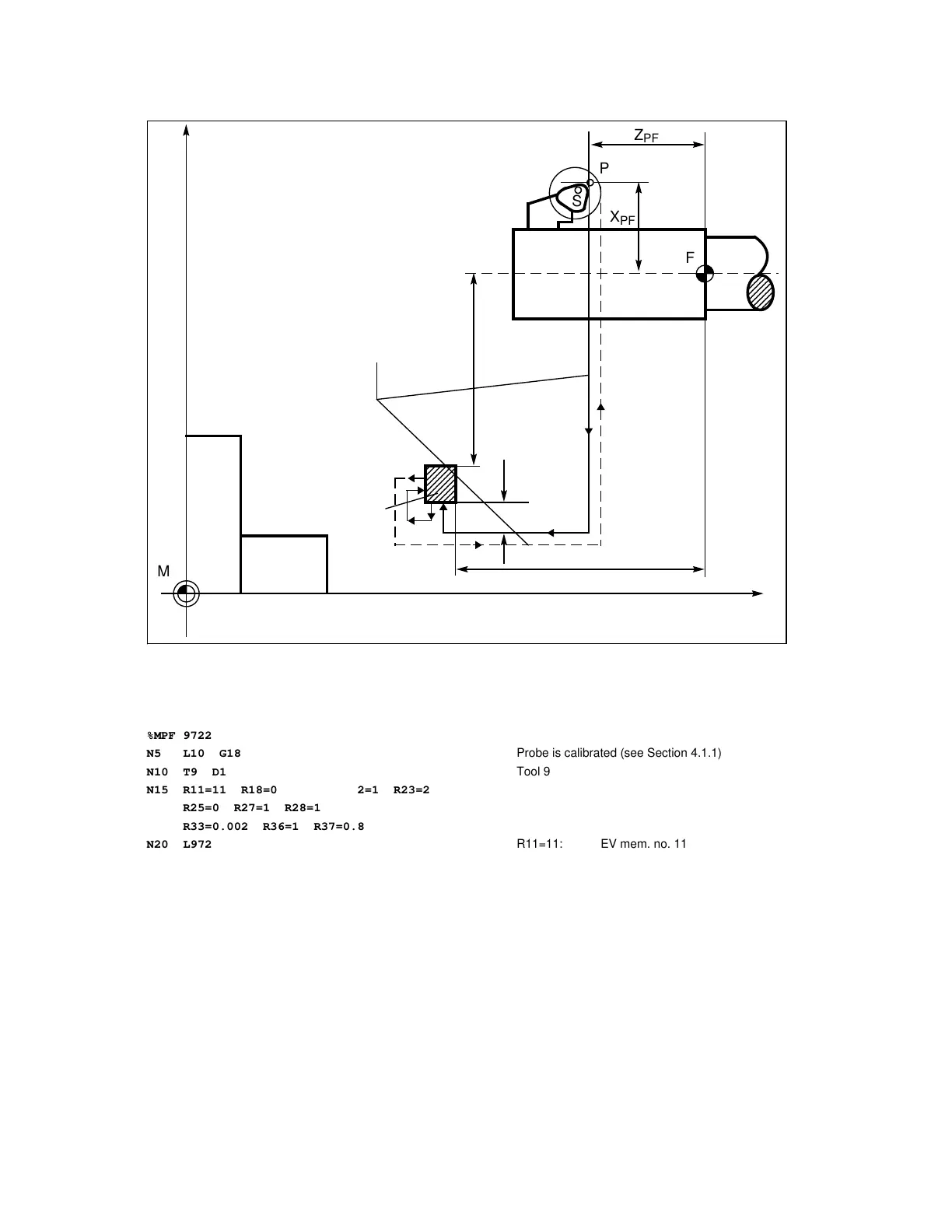

4.1.3 L972/L982 Automatic tool measurement

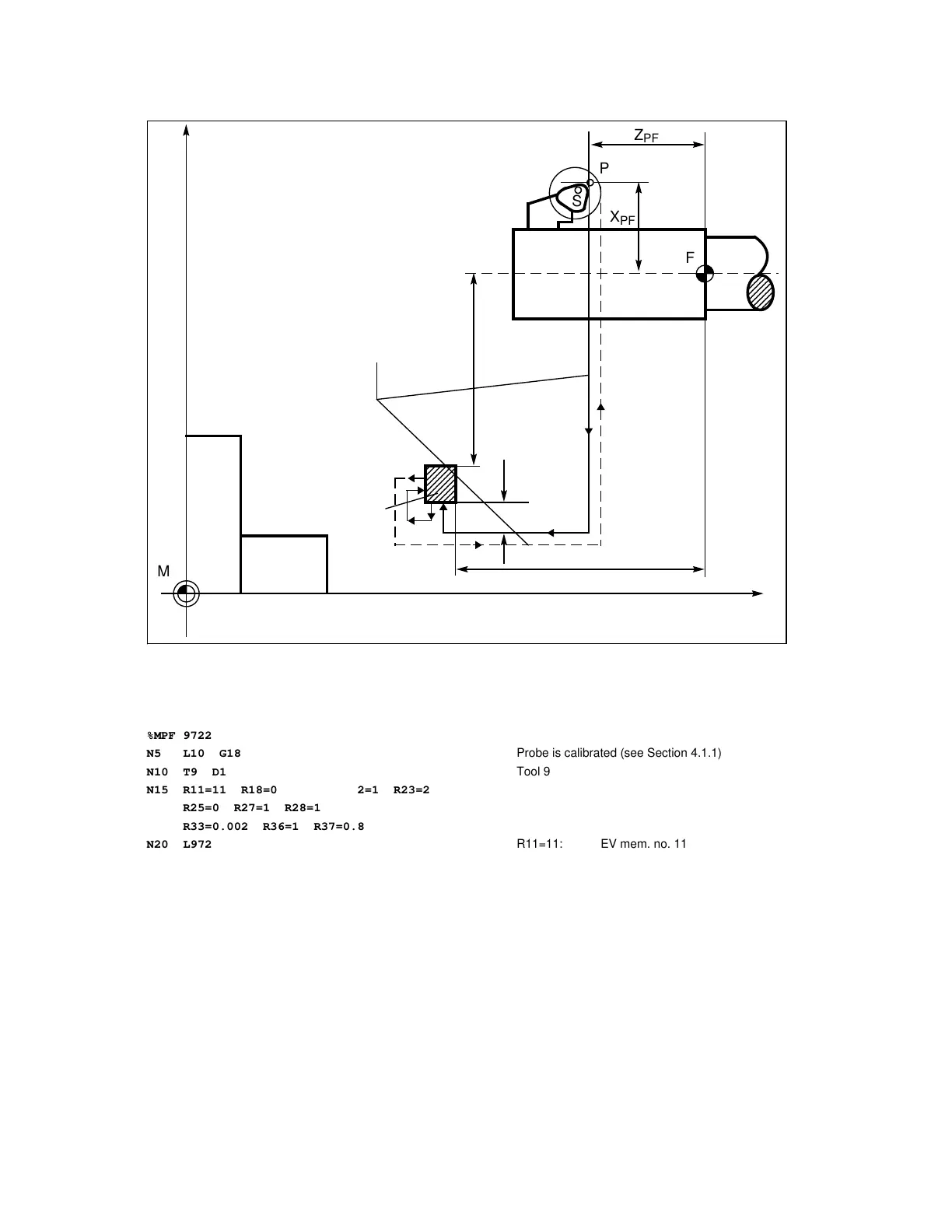

Example: Tool measuring program

Fig. 4.6 Tool measurement towards spindle tool type 1

Probe

Approach blocks

generated by

measuring cycle

itself

X

Z

R19

R18

R28

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

S

Z

PF

P

X

PF

F

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

M

%MPF 9722

N5 L10 G18 Probe is calibrated (see Section 4.1.1)

N10 T9 D1 Tool 9

N15 R11=11 R18=0 R19=0 R22=1 R23=2

R25=0 R27=1 R28=1

R33=0.002 R36=1 R37=0.8

N20 L972 R11=11: EV mem. no. 11 Z axis

EV mem. no. 12 X axis

R18=0: Change position X axis (MDC)

R19=0: Change position Z axis (MDC)

L972: Tool T9 is measured in the

Z and X axes

N25 T11 Tool 11

N30 R11=13 L972 R11=13: EV mem. no. 13 Z axis

EV mem. no. 14 X axis

L972: Tool T11 is measured in the

Z and X axes

N90 M30

© Siemens AG 1990 All Rights Reserved 6FC5197- AB70 4–19

SINUMERIK 840/850/880 (BN)

Loading...

Loading...