INTRODUCTION TO SPLICE INTERFACE

11

INTRODUCTION TO SPLICE INTERFACE

12

The red symbol displayed at the bottom left of the LCD.

Camera fault: first clean the objective lens, and then upgrade the welding machine firmware to the latest

version. If the fault still exists, please conduct self-inspection of the welding machine to confirm whether the

camera fails (please refer to daily maintenance for specific operation).

Core failure: first exclude the fiber treatment unqualified factors, such as the coating layer is not clean, too bad

cutting surface, too many burrs; Then clean up the V slot and objective lens and press the reset key.

Note: dust in the lens may also cause failure of core alignment, so dust should be cleaned (please refer to daily

maintenance for specific operation).

Focus failure: this tip only appears when autofocus is turned on, usually because the fiber image is too blurry

for the range of autofocus.Solution: first eliminate the fiber treatment unqualified factors, such as the coating

layer is not clean, too bad cutting surface, too many burrs; Then clean the V slot and objective lens, press the

reset key; Autofocus can also be turned off and adjusted manually (see daily maintenance for details). If the

fault continues, enter the welding machine self-check mode to check whether items 5 and 6 are wrong.

Note: dust in the lens may also cause failure of core alignment, so dust should be cleaned (please refer to daily

maintenance for specific operation).

Discharge correction failure:First clean the tip of the electrode and remove debris; Restore the factory Settings

in the device's fusion setting. Restart welding machine and zhuoshizhangzhongbao +, re-discharge correction.

If the fault continues, enter the welding machine self-check mode to check whether item 11 is wrong.

The left and right optical fibers do not match: the specifications or types of optical fibers on both sides are

Intelligent prompt and fiber state prompt solution

Intelligent prompt

different, and they need to be replaced with the same specifications or types.This error, can press continue to

ignore the key error, mandatory welding.

Note: according to the construction specifications of welding machine, different specifications and types of fiber

cannot be fused, if forced welding, welding quality may be affected.

Fog or foreign matter interference in the lens: firstly exclude the unqualified factors of the optical fiber

treatment, such as not scraping the coating layer, too bad cutting surface, too many burrs, and so on, and then

clean the objective lens;In addition, if the red light on the electrode fails, it may report an error. Please check it

(Open the electrode cover, and the indicator is on all the time. If not, it is broken and needs to be replaced.).

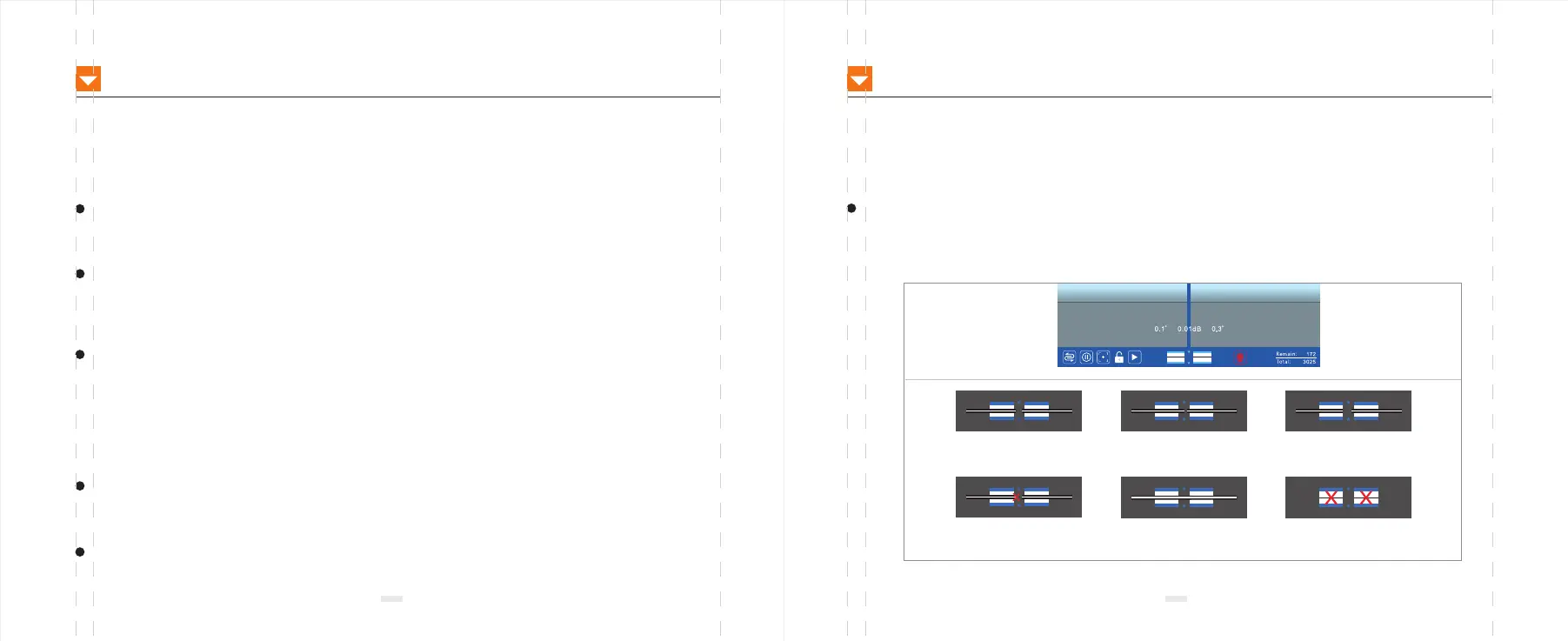

Flash on both sides

please place fiber

Left fiber is too long

(also adapted to right)

Left fiber is too short

(also adapted to right)

Left end face is unqualified

(also adapted to right)

Detection fiber qualified If the qualified fiber is not recognized

or the fiber is not detected, please

clean the v-groove and reposition it

Fiber status prompt description

Ⅰ

Loading...

Loading...