83

IT

ES

PT

GB

RUS

4.1 ADJUSTMENT OF

D.H.W. FLOW RATE

To adjust the hot water flow rate, use the

flow-rate regulator on the pressure switch

valve (5 fig. 5).

Remember that the flow rates and corre-

sponding temperatures of use of hot water,

given in section 1.3, have been obtained by

positioning the selector of the circulation

pump on the maximum value.

Should there be any reduction in the D.H.W.

flow rate, the filter installed on the inlet to

the pressure switch valve (3 fig. 5) will need

cleaning.

To access the filter, you must first

turn off the cold domestic water tap assem-

bled on the template.

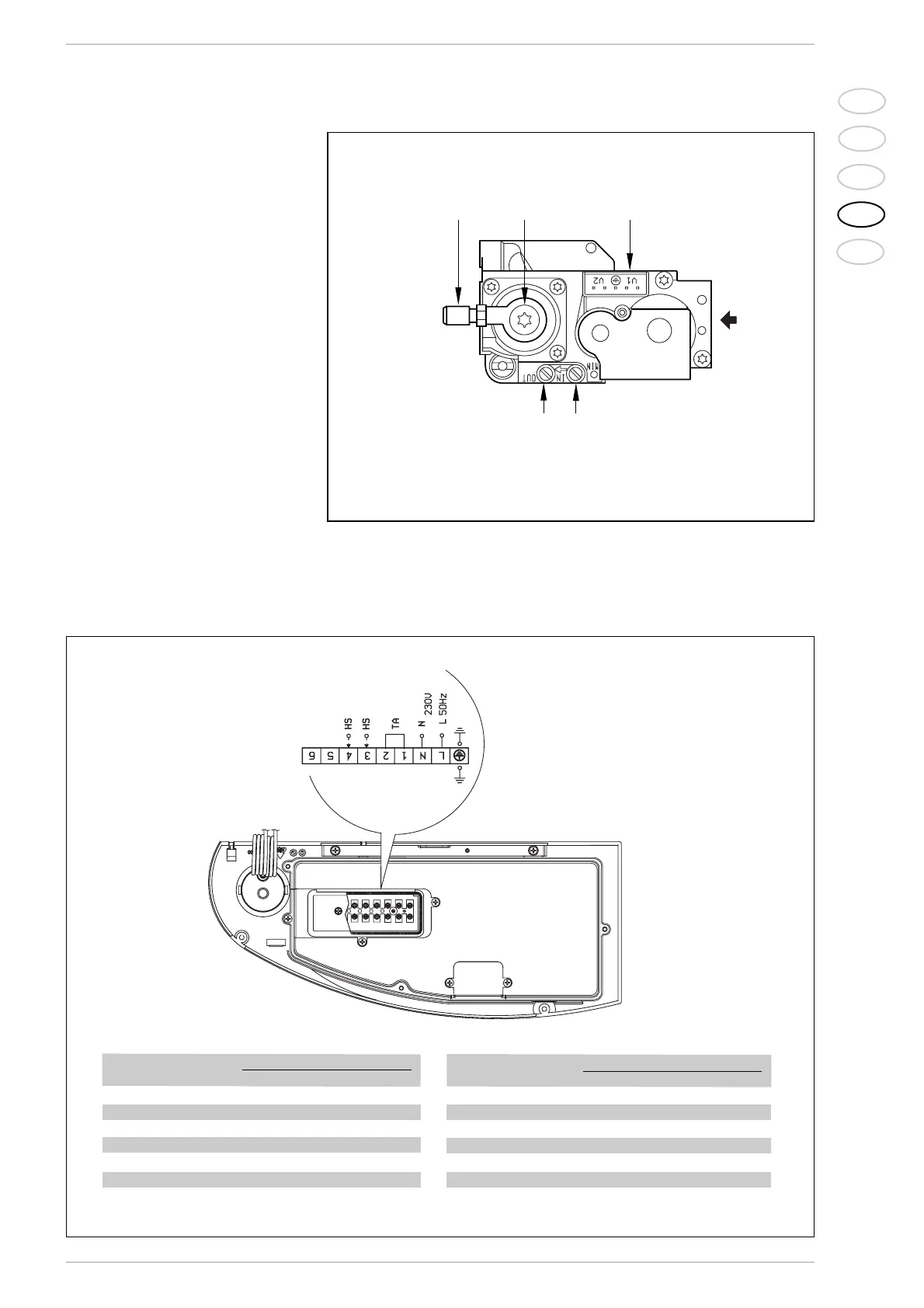

4.3 GAS VALVE

The boiler, is equipped standard with the

HONEYWELL VK 4115V gas valve (fig. 20).

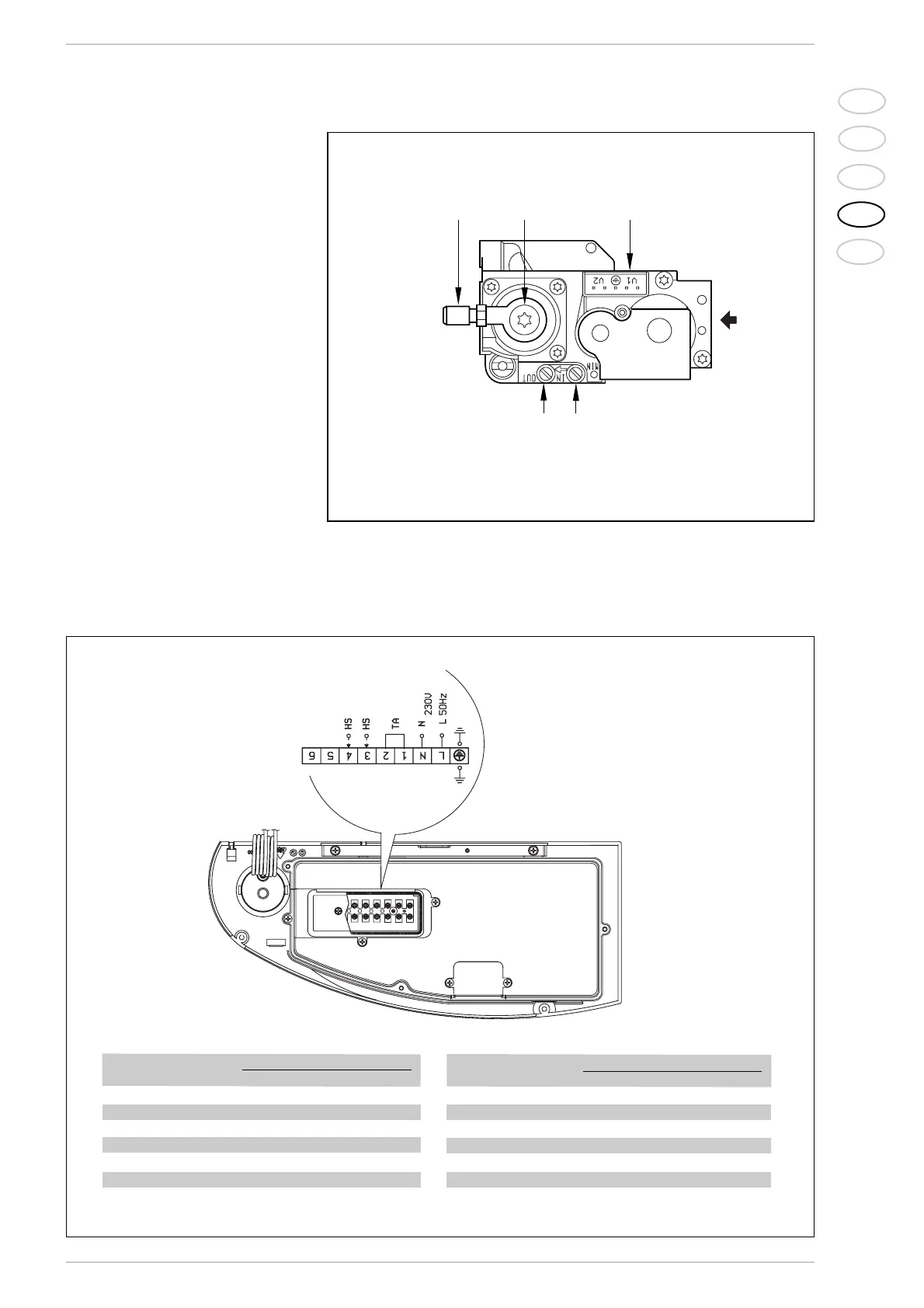

4.4 ADJUSTMENT OF HEAT

OUTPUT FOR HEATING

To adjust boiler heat output for heating pur-

poses, i.e., modifying the setting made at the

factory which is approximately 17 kW, use a

screwdriver to adjust the heating heat out-

put trimmer (6 fig. 17). To increase working

pressure, turn the trimmer clockwise; to

reduce pressure, turn the trimmer coun-

terclockwise. Output can be verified for both

methane and propane gas boilers by

checking the Hertz or air pressure mbar

value in Table 5 (fig. 21).

4 USE AND MAINTENANCE

KEY

1 VENT fixture

2 EV1-EV2 coils

3 Upstream pressure fixture

4 Downstream pressure fixture

5 OFF-SET

Tester points on “HS” terminals

for fan Hz readings.

Fig. 21

Hertz Air pressure Heat output “30 BF”

mbar (80/60°C) kW (50/30°C) kW

70 1,24 10,2 11,3

90 2,05 14,6 16,1

110 3,06 16,6 18,2

130 3,71 20,5 22,5

150 4,94 24,5 26,7

185 7,52 29,4 32,1

TABLE 5

Hertz Air pressure Heat output “25 BF”

mbar (80/60°C) kW (50/30°C) kW

70 1,34 8,4 9,3

90 2,32 10,7 11,7

110 3,56 14,6 16,0

130 5,06 16,5 18,0

150 7,66 20,4 22,2

185 9,41 24,2 26,4

Loading...

Loading...