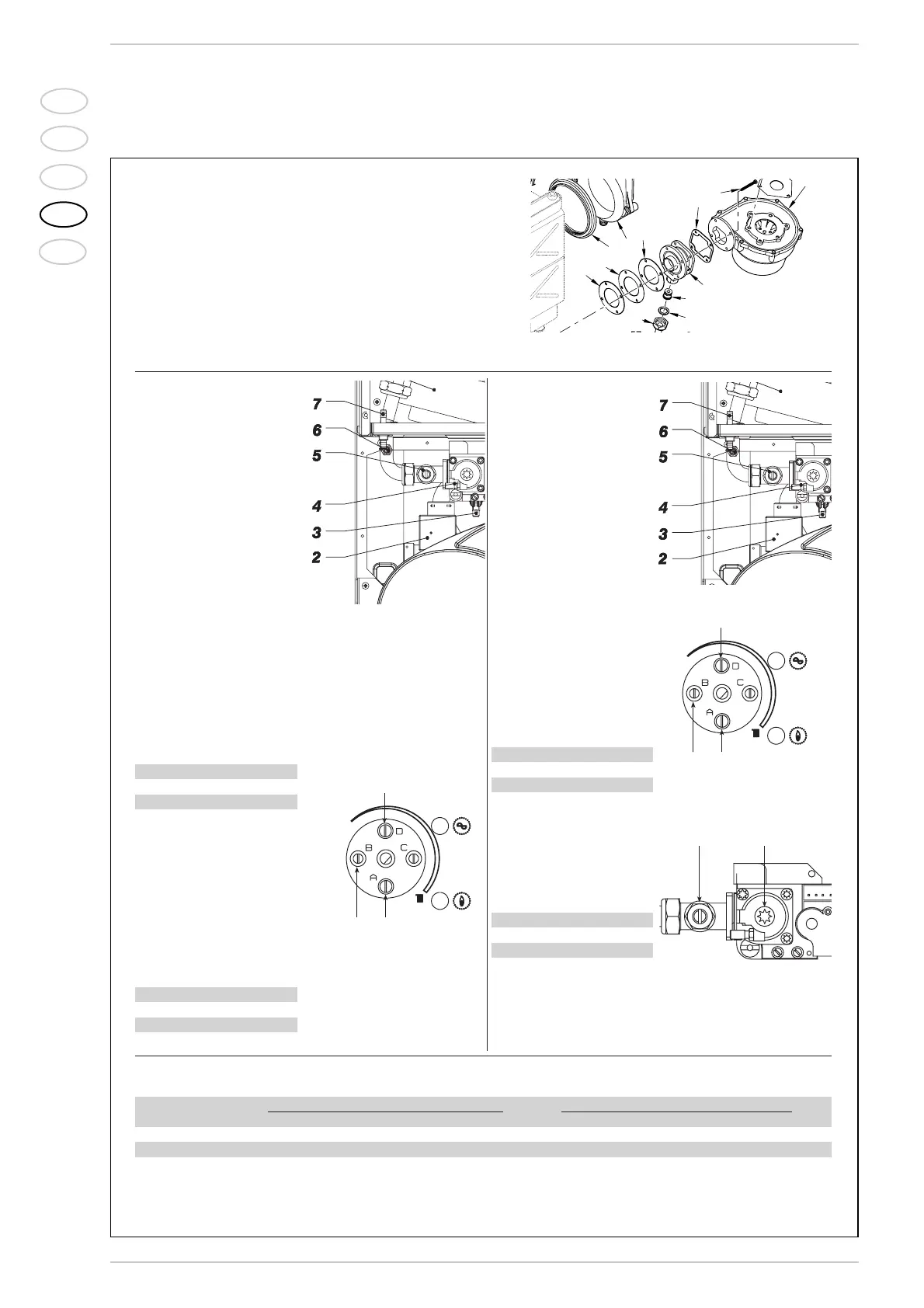

AIR CALIBRATION

Electrically disconnect the hea-

ting probe (SM) and connect

the wires to another similar

free probe. Turn the heating

potentiometer knob to the

maximum setting, remove the

knob and connect the differen-

tial manometer (+ sign) to the

air pressure intake [7 - Drawing

1].

Sequence of operations:

1) Turn the heating power trim-

mer anticlockwise to the

bottom of the scale B [6 -

Drawing 2].

2) Calibrate the air signal using

the minimum fan power

adjustment trimmer A [4 -

Drawing 2] to obtain the

figure in mmH

2O shown in

the table:

3) Turn on a hot water tap to

bring the boiler up to maxi-

mum hot water power.

4) Calibrate the air signal using

the maximum fan power

adjustment trimmer D [2 -

Drawing 2] to obtain the

figure in mmH

2

O shown in

the table:

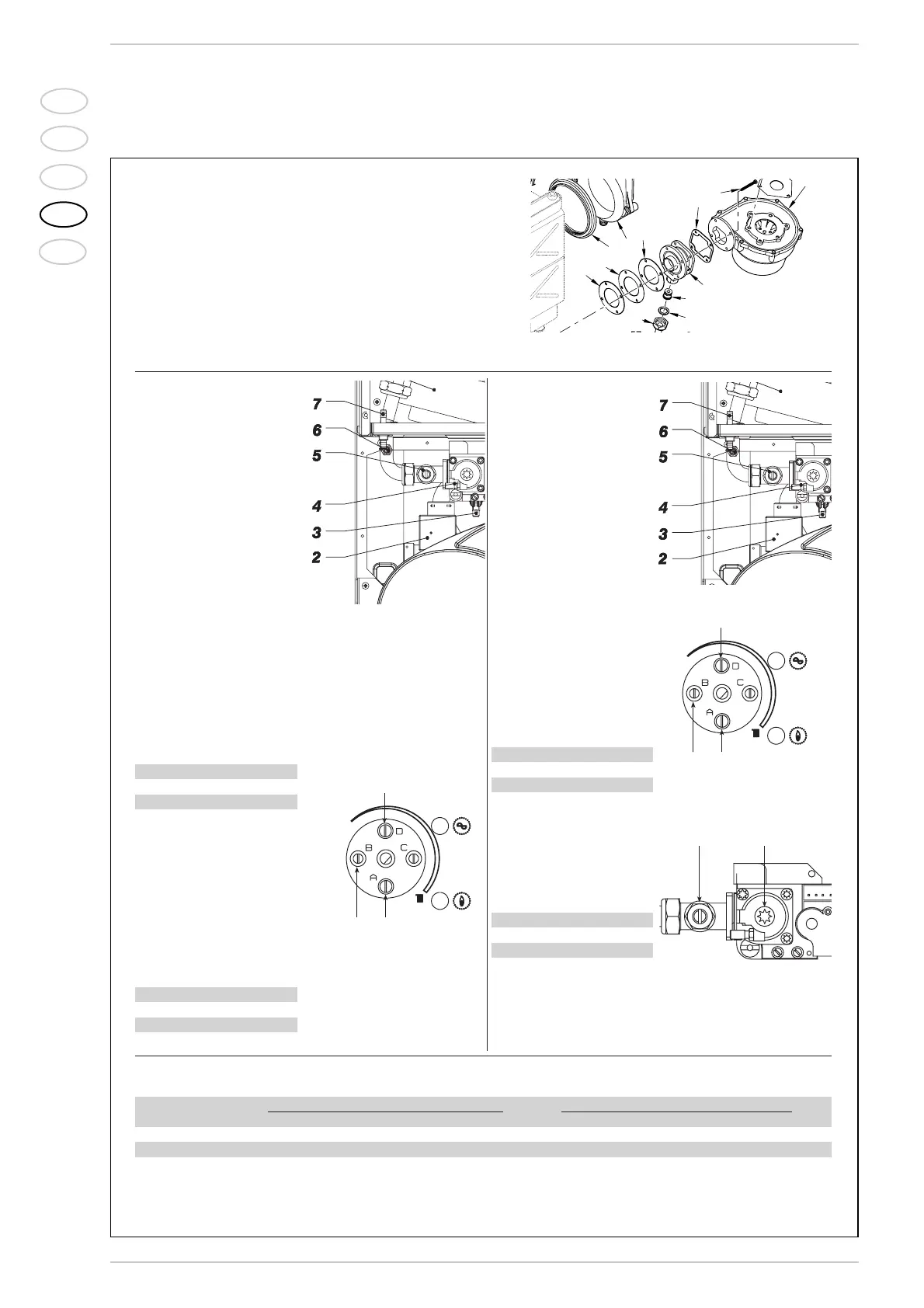

GAS CALIBRATION

Connect the differential mano-

meter (+ sign) with decimal

scale in mm or Pascal to the

gas intake [6 - Drawing 3].

Sequence of operations:

1) Turn the heating power adju-

stment trimmer anticlockwi-

se to the bottom of the

scale B [6 - Drawing 4].

2) Fully open the gas capacity

step [7 - Drawing 5]

3) Calibrate gas pressure

using the OFF-SET adjust-

ment screw [8 - Drawing 5]

to obtain the figure in

mmH

2

O shown in the table:

4) Close the gas capacity step

[7 - Drawing 5] to obtain the

figure in mmH

2

O shown in

the table:

After completion of calibration operations, check CO

2

values using a combustion analyser. If discrepancies are found with respect to the

values appearing in the tables, correct as necessary:

– Use the OFFSET screw (

8 – Drawing 5

) to correct CO

2

at “MIN” output.

– Use the capacity step to correct CO

2 at “MAX” output (

7 – Drawing 5

).

25 BF 30 BF

G20 13,0 13,0

G31 13,0 13,0

“Format Dewy.zip 25 BF” “Format Dewy.zip 30 BF”

CO

2

(Methane) CO

2 (Propane) CO

2

(Methane) CO

2

(Propane)

“MIN” power 9,0 ±0,3 9,9 ±0,2 9,0 ±0,3 9,9 ±0,2

“MAX” power 9,0 ±0,3 9,9 ±0,2 9,0 ±0,3 9,9 ±0,2

GAS CONVERSION

– Close the gas cock.

– Replace the injector (pos. 30)

and the relevant gasket (pos.

45).

–

Cut the specified resistance on

the fan control board.

– Test for soundness all the gas

connections using soapy water

or appropriate products.

DO NOT USE NAKED FLAMES.

– Stick onto the casing panel the

plate showing the relevant fee-

ding gas.

– Proceed with air and gas cali-

bration as described below.

Loading...

Loading...