presenting high head losses.

At each restart after the period of slow

ignition, the boiler will set itself for about

1 minute at the minimum modulation

pressure, and will then move to the hea-

ting pressure value set.

When the connecting link is inserted,

both the programmed technical pause

and the period of operation at minimum

pressure in the startup phase will be

cancelled. In this case, the times ela-

psing between turning off and subse-

quent re-ignition will depend on a tempe-

rature difference of 5°C detected by

the C.H. sensor (SM).

ATTENTION: It is essential that the opera-

tions described above be carried out by

authorized technical staff.

3.2 TEMPERATURE SENSOR

The “METRÒ” boiler is equipped with sen-

sor for detecting heating temperature.

The sensor acts as a limit stat, switching-

off the burner when the temperature mea-

sured is higher than 85°C; the reset tem-

perature is set at 80°C.

When C.H. sensor (SM) has tripped, the

boiler will not function for either service.

Table 3 shows the resistance values (Ω)

that are obtained on the sensor as the

temperature varies.

3.3 ELECTRONIC IGNITION

Ignition and flame detection is controlled by

an electrode located on the burner.

These guarantee maximum safety with

intervention times, for accidental switching

off or gas failure, of within one second.

3.3.1 Operating cycle

Rotate the rotary switch to summer or win-

ter, the red led should light up.

Burner ignition normally takes place within

10 seconds.

However, it is possible for igni-

tion failures to occur, with consequent

activation of signal indicating that the con-

trol box has “locked out”.

– Gas failure

The control box runs through the cycle

normally sending electric power to the

ignition electrode.

The electrode continues spark discharge

for a maximum of 10 sec.

If the burner does not ignite, the control

box “locks out”.

This may occur upon first ignition or

after long periods of boiler lay-off when

there is air in the pipes.

It may be caused by the gas cock being

closed or by one of the valve coils having

a break in the winding, so that the valve

cannot open.

– Ignition electrode fails to spark

In the boiler, only the gas to the burner is

seen to open. After 10 sec. the control

box “locks out”.

This may be due to a break in the wire of

the electrode or to the wire not properly

fastened to the electric terminal of the

ignition transformer.

The electrode is earthed or very worm

and needs to be substituted.

The control box is defective.

When there is a sudden voltage failure, the

burner shuts out immediately; when power

supply returns, the boiler will start up again

automatically.

3.4 “25 OF” SMOKE

SAFETY DEVICE

This is a safety device against possible

smoke emission into the ambience (15 fig.

3). The safety device goes into action by

blocking operation of the gas valve when the

return of the smoke into the ambience is

continuous and in quantities that might con-

stitute a danger. To restart the boiler reac-

tivate the button of the thermostat.

Should the boiler continue to “lock out”, it will

be necessary to make a careful check on

the flue pipe, making all the necessary modi-

fications and amendments so that it can

work properly.

Check for proper functioning after all work on

the device. If you must replace a part, use only

original Sime spare parts.

NOTE: The device must not be turned off.

3.5 “25 BF” SMOKE

PRESSURE SWITCH

The pressure switch with fixed settings 4.5-

6 mm H

2

O

is able to guarantee the boiler

operation even with air intake and smoke

outlet pipes at the maximum limit of the

length allowed (10 fig. 3).

Impurities and possible formations of

condensate, which are more likely in cold

periods of the year, could lead the pres-

sure switch not to work and the boiler

fail to start.

3.6 NO WATER FLOW

SAFETY DEVICE

The boiler has a flow switch (8 fig. 6) which

is tripped when it does not detect water

flow in the primary circuit (>400 l/h), pre-

venting the burner from functioning.

To start the burner again, check the pres-

sure in the system and make sure that

the pump and the flow switch are working

properly.

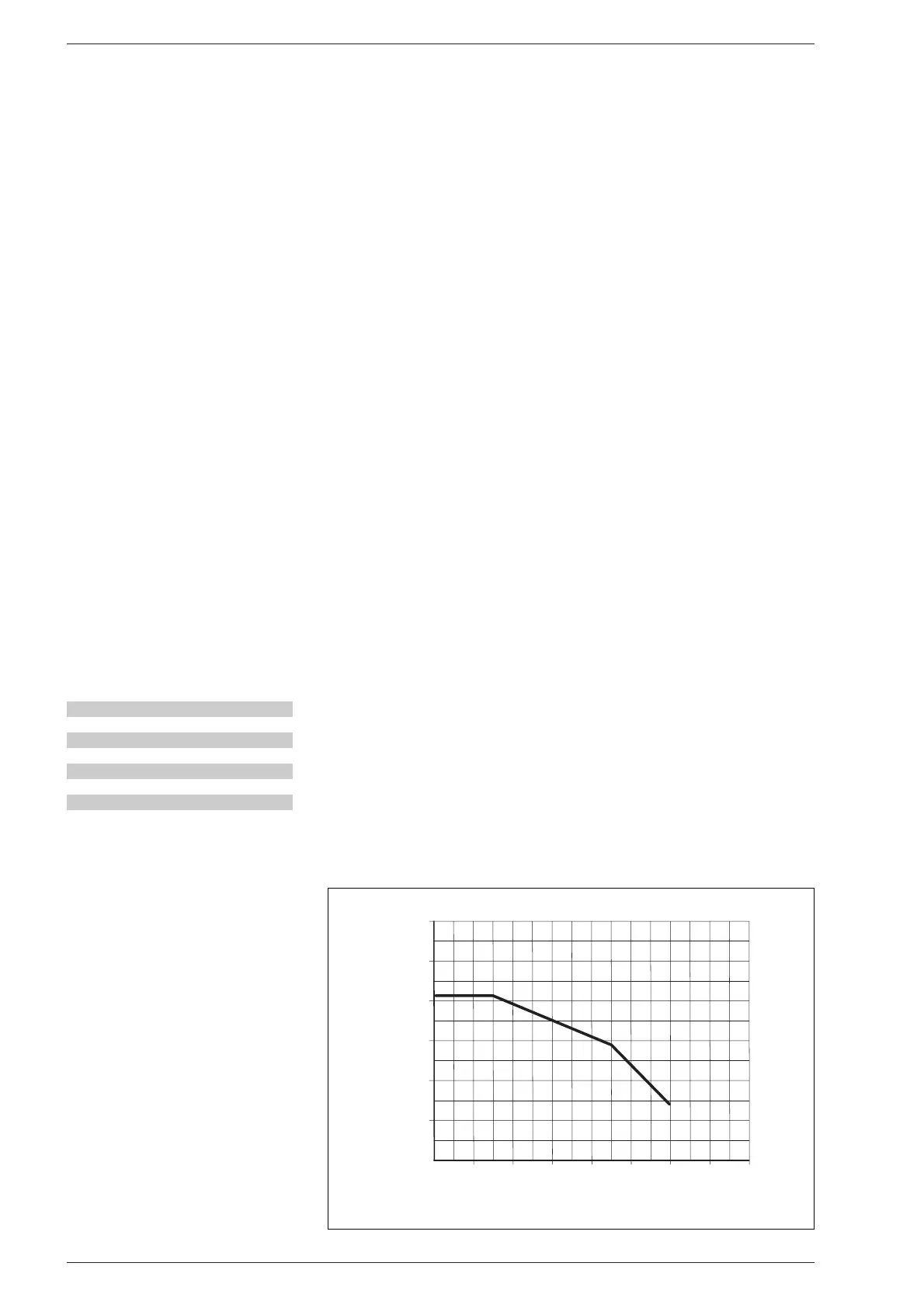

3.7 SYSTEM AVAILABLE HEAD

The head available for the heating plant is

shown as a function of the flow in graph in

fig. 20.

3.8 TIME PROGRAMMER

(optional)

The control panel allows a time program-

mer to be utilised for the management of

the heating, supplied on request in the kit

81

TABLE 3

Temperature (°C) Resistance (Ω)

20 12.090

30 8.313

40 5.828

50 4.161

60 3.021

70 2.229

80 1.669

Loading...

Loading...