4.1 TEMPERATURE

ADJUSTMENT OF D.H.W.

The sistem with a potentiometer for adju-

sting the temperature of D.H.W. with a set-

ting range from 30° to 60°C offers a dou-

ble advantage:

1) The boiler adapts perfectly to any type of

D.H.W. system, whether the mixing

system is a mechanical or a thermostat-

controlled type.

2) The thermal output is dosed according

to the temperature required, which

means a considerable saving in fuel.

NOTE: In order to avoid any misunder-

standing please remember that the value

obtained by the product of temperature

difference (in °C) between D.H.W. output

and input into the boiler by the hourly

flow rate measured on the tap, where

hot water is drawn off (l/h), cannot be

higher than the useful output developed

by the boiler. For measurements and

checks on flow rate and temperature of

D.H.W., use suitable instruments, taking

into consideration any heat dispersion

along the stretch of piping between the

boiler and the measuring point.

4.2 ADJUSTMENT OF

D.H.W. FLOW RATE

To adjust the D.H.W. flow rate, use the flow

rate adjuster (5 fig. 6).

Remember that the flow rates and corre-

sponding temperatures of use of hot water,

given in section 1.3, have been obtained by

positioning the selector of the circulation

pump on the maximum value.

Should there be any reduction in the

D.H.W. flow rate, the filter installed on the

inlet to the divertor valve (3 fig. 6) will

need cleaning.

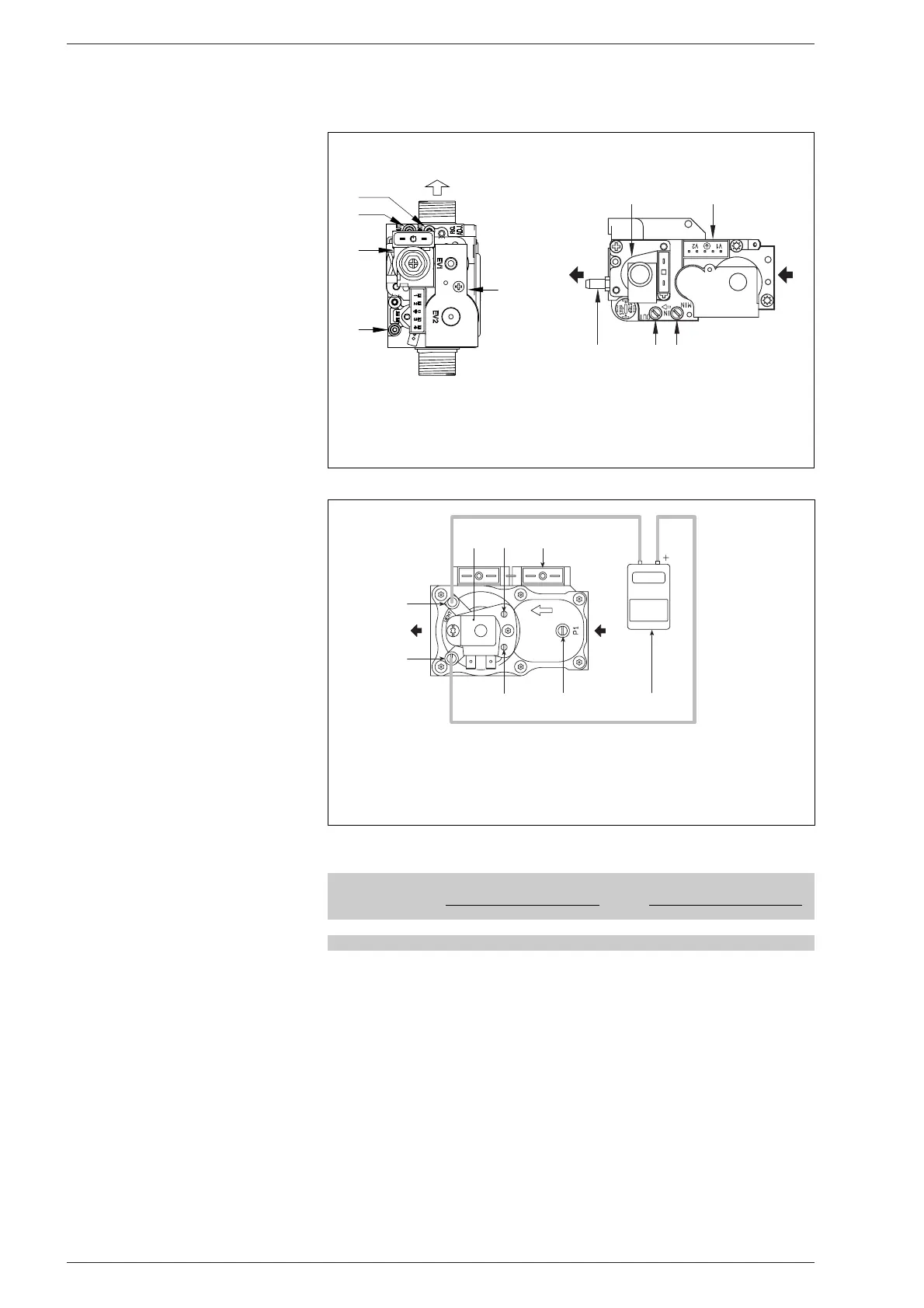

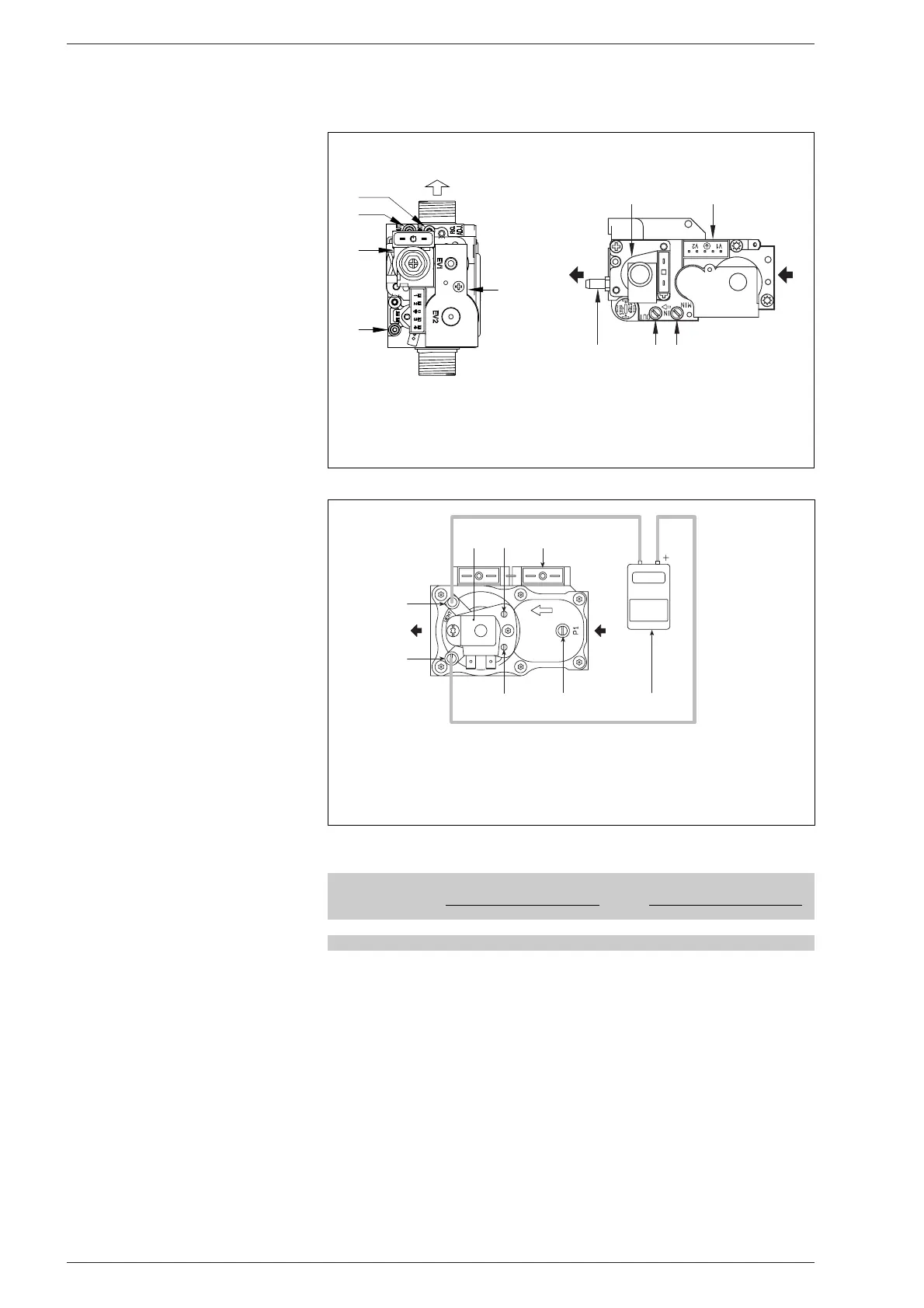

4.3 GAS VALVE

The boilers are equipped standard with the

SIT 845 SIMGA/HONEYWELL VK 4105M

gas valve (fig. 23) and WHITE-RODGERS

91B05S. gas valve (fig. 24).

The gas valve is set at two pressure values:

maximum and minimum.

According to the type of gas burnt, these

correspond to the values given in Table 4.

The gas pressures at the maximum and

minimum values, are factory set. Conse-

quently they must not be altered.

Only when you switch the appliance from

one type of gas supply (methane) to

another (butane or propane), it is permit-

ted to alter the operating pressure.

It is essential that this operation is carried

out exclusively by authorized technical

staff. When the working pressures have

been adjusted, reseal the regulators.

When the gas pressures are to be reset,

this must be done following a set order

depending on the type of valve:

– First the MAXIMUM and then the MINI-

MUM for the SIT 845 SIGMA and

HONEYWELL VK 4105M

gas valve.

–

First the MINIMUM and then the MAXI-

MUM for the WHITE-RODGERS

91B05S gas valves.

4.3.1 Maximum and minimum

pressure adjustment

SIT 845 SIGMA

To set the maximum pressure, proceed as

follows (fig. 25):

–

Connect the pressure column to the pres-

sure inlet downstream of the gas valve.

– Remove the plastic cap (1).

– Set the knob of the D.H.W. potentiome-

ter to the maximum value.

–

Ignite the boiler and open the hot

water cock.

–

Using a ø 10 spanner, turn the nut (3)

to arrive at the maximum pressure

value given in Table 4: to reduce the

pressure, turn the nut counterclockwi-

se; to increase the pressure, turn it

clockwise.

–

Operate the main switch a number of

times, keeping the hot water tap open

all the time, and check that the pressu-

re corresponds to the values given in

Table 4.

83

4 USE AND MAINTENANCE

TABLE 4

Burner max. Modulator Burner min. Modulator

Type of gas pressure current pressure current

mbar mA mbar mA

Methane (G20) 9,5 130 1,4 0

Butane (G30) 27,7 165 5,1 0

Propane (G31) 35,3 165 6,1 0

Loading...

Loading...