After having adjusted the maximum pressu-

re, calibrate the minimum pressure as fol-

lows (fig. 25):

– Disconnect the electric power to the

modulator.

–

With the D.H.W. potentiometer knob on

maximum, the D.H.W. cock open and the

burner ignited, turn the screw (2) keeping

locked the nut (3) to achieve the mini-

mum pressure value given in Table 4: to

reduce the pressure, turn the screw

counterclockwise; to increase the pressu-

re, turn it clockwise.

–

Operate the main switch a number of

times, keeping the D.H.W. tap open all the

time, and check that the pressure corre-

sponds to the values given in Table 4.

– Restore electric power to the modulator.

– Replace the plastic cap (1) in position.

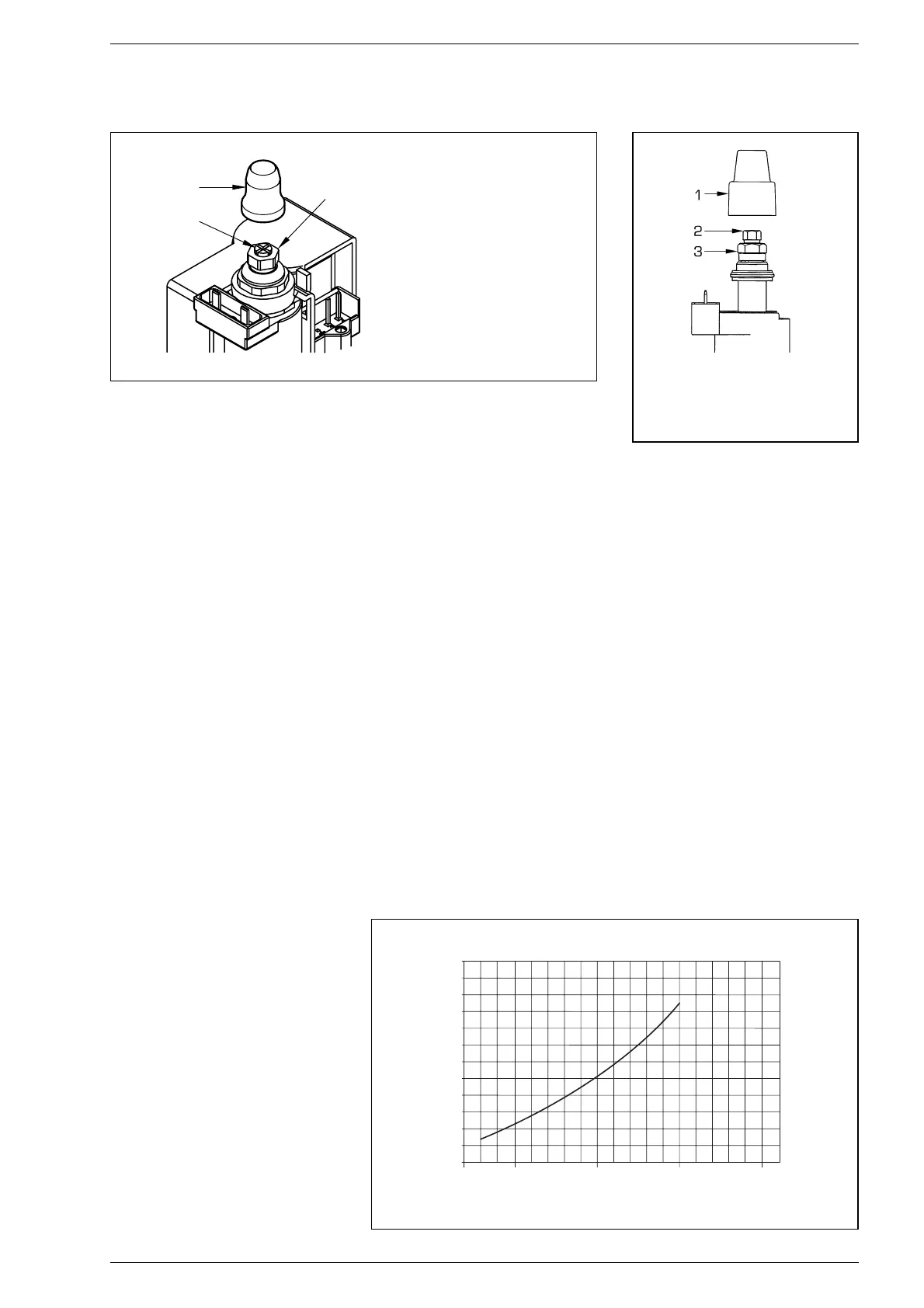

4.3.2 Maximum and minimum

pressure adjustment

HONEYWELL VK 4105M

To set the maximum pressure, proceed as

follows (fig. 26):

–

Connect the pressure column to the pres-

sure inlet downstream of the gas valve.

– For the “BF” models connect the pressu-

re column as shown in fig. 24.

– Remove the plastic cap on the modula-

tor (1).

– Set the knob of the D.H.W. potentiome-

ter to the maximum value.

– Ignite the boiler and open the D.H.W. cock.

– Using a ø 9 spanner, turn the nut (3) to

achieve the maximum pressure value

given in

Table 4

: to reduce the pressure,

turn the nut counterclockwise; to increa-

se the pressure, turn it clockwise.

–

Operate the main switch a number of

times, keeping the D.H.W. cock open all the

time, and check that the pressure corre-

sponds to the values given in Table 4.

After adjusting maximum pressure, pro-

ceed to calibrate minimum pressure (fig.

26):

–

Disconnect the electric power supply

from the modulator.

–

With the hot water potentiometer

knob set to the maximum, the hot

water tap turned on and the burner lit,

hold nut (3) locked in place and simulta-

neously turn nut (2) using a fixed ø 7

wrench to identify the minimum pres-

sure value shown in Table 4: turn the

nut anti-clockwise to reduce pressure

or clockwise to increase it.

– Turn the boiler on and off repeatedly

while keeping the hot water tap turned

on, checking that pressure corresponds

to the values shown in Table 4.

– Connect up the power supply to the

modulator again.

– Replace the plastic cap (1).

4.3.3 Minimum and maximum

pressure adjustment

WHITE-RODGERS 91B05S

To set the minimum and maximum pressu-

res, proceed as follows:

–

Connect the manometer as shown in

fig. 24.

– Set the knob of the D.H.W. potentiome-

ter to the maximum value.

– Ignite the boiler and open the D.H.W. cock.

–

Turn the screw (7 fig. 24) to achieve the

minimum pressure value given in Table 4:

to reduce the pressure, turn the screw

counterclockwise; to increase the pressu-

re, turn it clockwise.

– Turn the screw (6 fig. 24) to achieve the

maximum pressure value given in Table 4:

to reduce the pressure, turn the screw

counterclockwise; to increase the pressu-

re, turn it clockwise.

–

Operate the main switch a number of

times, keeping the D.H.W. cock open all

the time, and check that the pressure cor-

responds to the values given in Table 4.

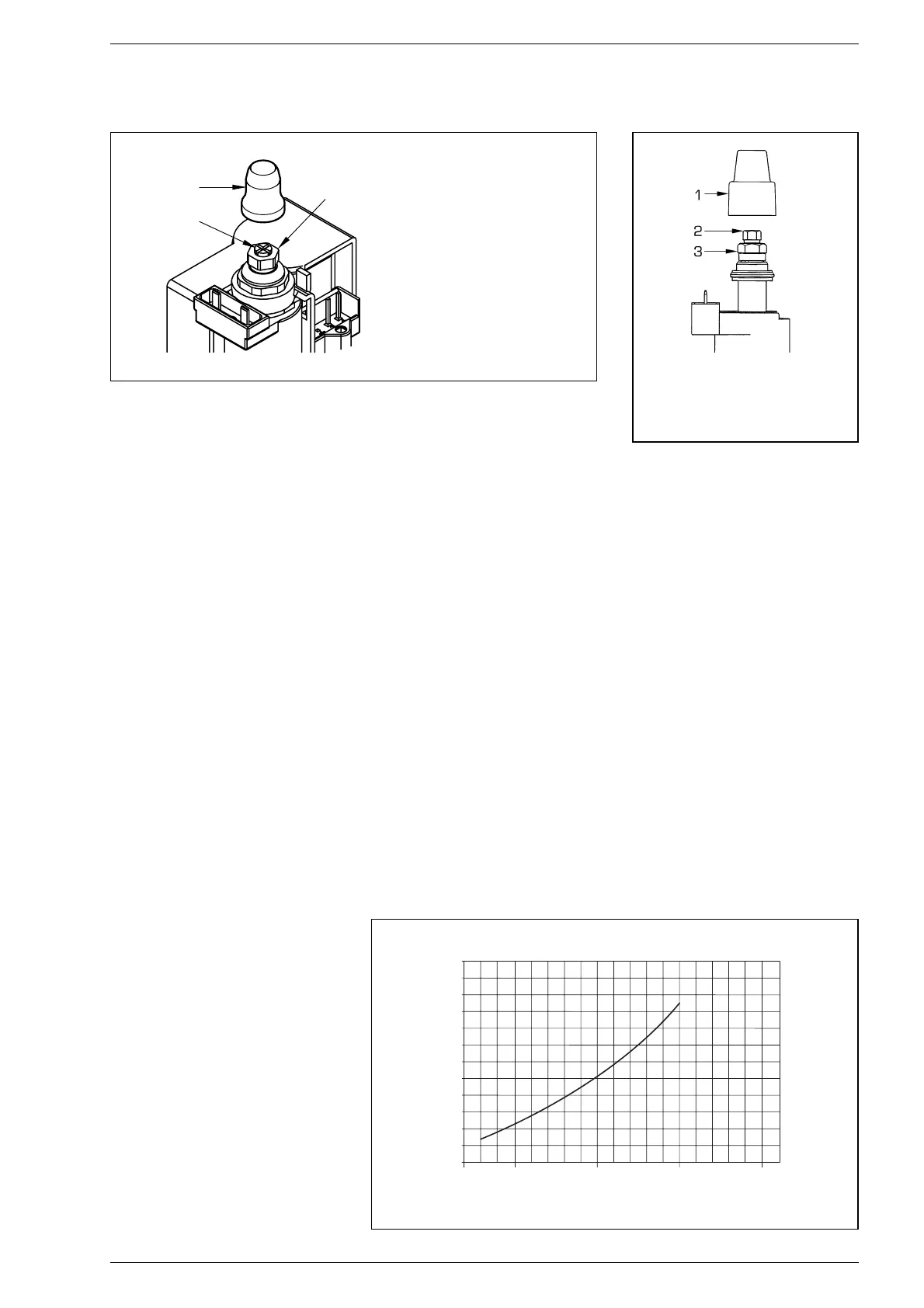

4.4 ADJUSTMENT OF HEAT

OUTPUT FOR HEATING

To adjust boiler heat output for heating pur-

poses, i.e., modifying the setting made at the

factory which is approximately 16 kW, use a

screwdriver to adjust the C.H. heat output

trimmer (1 fig. 19). To increase working

pressure, turn the trimmer clockwise; to

reduce pressure, turn the trimmer coun-

terclockwise. To facilitate the operations of

adjusting heat output, see the

pressure/heat output diagrams for natural

gas (methane) and butane or propane gas

(figg. 27 - 27/a - 27/b).

84

Loading...

Loading...