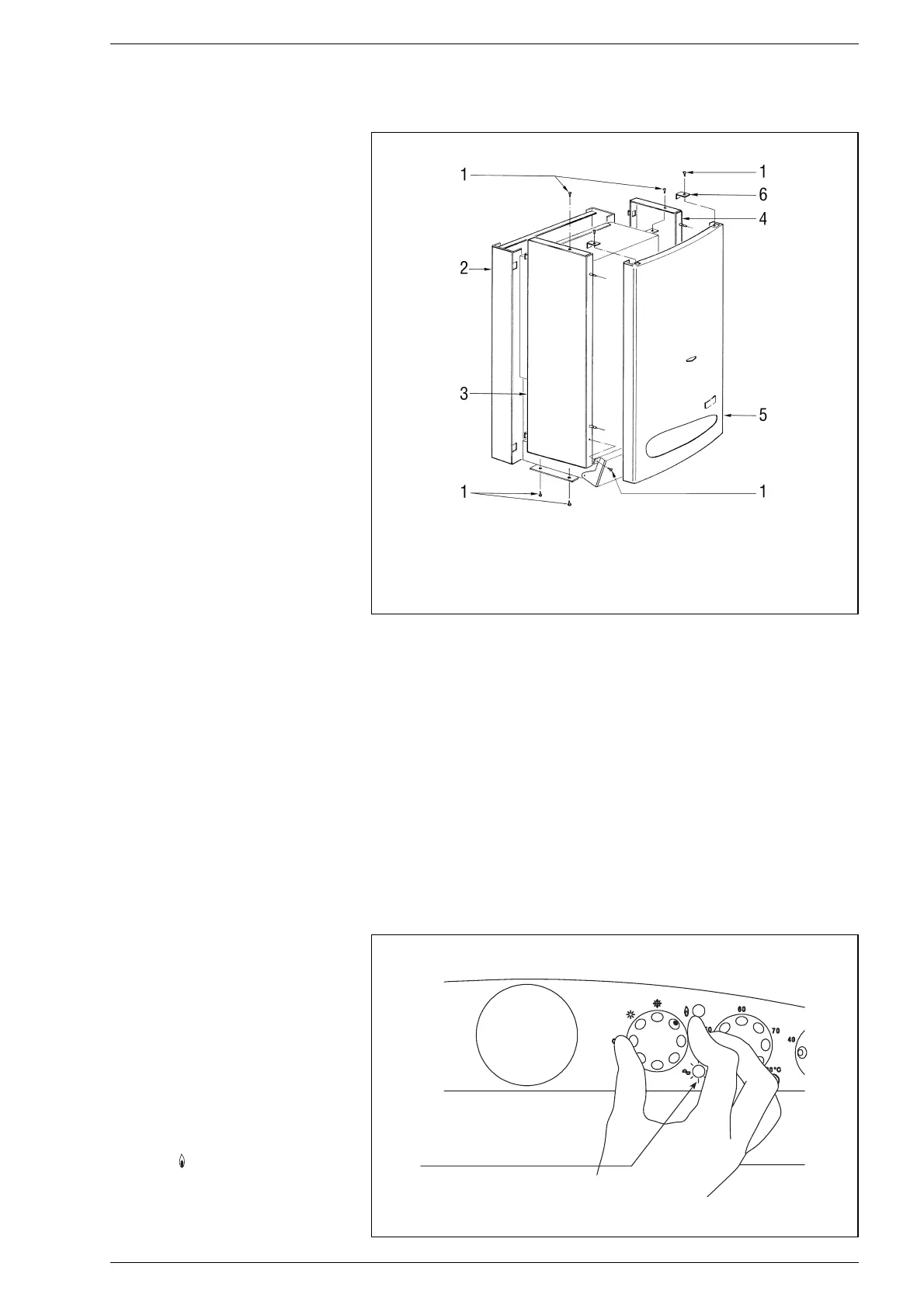

4.7 REMOVAL OF OUTER CASING

It is possible to completely disassemble the

shell for an easy maintenance of the boiler

following these simple instructions (fig. 30):

– Remove the two screws and bracket (6)

locking the front panel to the sides.

– Pull the front panel forwards so as to

release it from the slot-in pins located on

the sides.

– Unscrew the two screws fixing the instru-

ment panel to the sides.

– Unscrew the four screws fixing the sides

to the instrument panel support.

–

Push the sides (3) and (4) upwards, sliding

them out of their slots in the frame (2).

4.8 CLEANING AND

MAINTENANCE

Carry out the cleaning of the generator in

the following way:

– Turn the main switch off to stop electric

power reaching the boiler and close the

gas feed cock.

– Remove the outer casing as described in

section 4.7.

– Remove the gas burner manifold unit

(fig. 28).

– To clean the burner, blow in a jet of air, so

as to remove any dust particles that may

have accumulated.

– Clean the heat exchanger, removing any

dust or residue from combustion.

– When cleaning the heat exchanger or

the burners, chemical products or steel

brushes MUST NOT BE USED.

–

Make sure that the tops of the burners

with the holes are free from encrustations.

– Reassemble the items removed from

the boiler, making sure to follow the cor-

rect sequence.

– Check the chimney to make sure that

the flue is clean.

– Check operation of the main burner.

– After assembly of all the gas connec-

tions, these must be tested for sound-

ness, using soapy water or appropriate

products.

DO NOT USE NAKED FLAMES.

– Do not use calcium chloride to treat the

plastic component during generator

maintenance.

Preventive maintenance and checking of

efficient operation of equipment and

safety devices must be carried out exclu-

sively by authorized technical personnel.

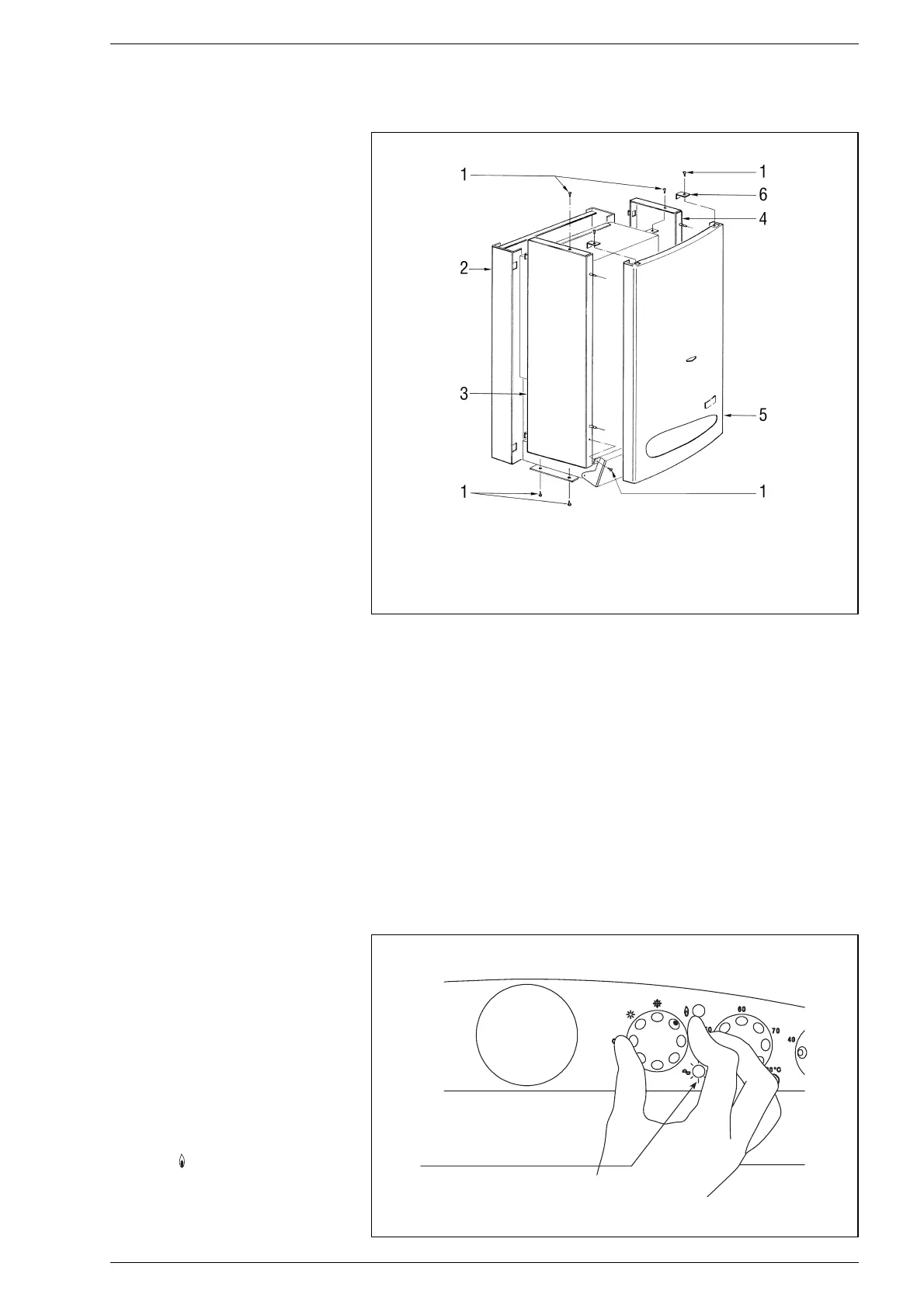

4.8.1 Chimney sweep

function

To carry out the verification of combustion

in the boiler turn the selector and stop on

the position ( ) until the green/ orange led

starts to flash intermittently (fig. 31).

From that moment the boiler will start func-

tioning in heating mode at the maximum

power (20,000 kcal/ h), with switching off

at 80°C and restarting at 70°C.

Before activating the chimney sweep func-

tion make sure that the radiator valves or

eventual zone valves are open.

The test may be carried out also during hot-

water service functioning.

To do so it is enough, after having activated

the chimney sweep function, to take some

hot water from one or more cocks.

Even in this condition the boiler functions

at the maximum temperature always

with the primary controlled between

80°C and 70°C.

During the entire duration of the testing the

hot water taps must remain open.

After verifying the combustion the boiler

should be switched off by placing the selec-

tor on the OFF position; then return the

selector to the desired function.

ATTENTION:

After about 15 minutes, or once the hot

water request has been fulfilled, the

chimney sweep function automatically

deactivates.

4.9 FAULT FINDING

The burner does not ignite and the circu-

lator is working.

– Check that the water pressure reads 1 -

1.2 bar.

– The flowmeter is faulty, replace it.

86

Fig. 30

KEY

1 Self-tapping screw

2 Frame

3 L.H. side panel

4 R.H. side panel

5 Front panel

6 Fixing bracket

Loading...

Loading...