5

HTE302172 19/46

6

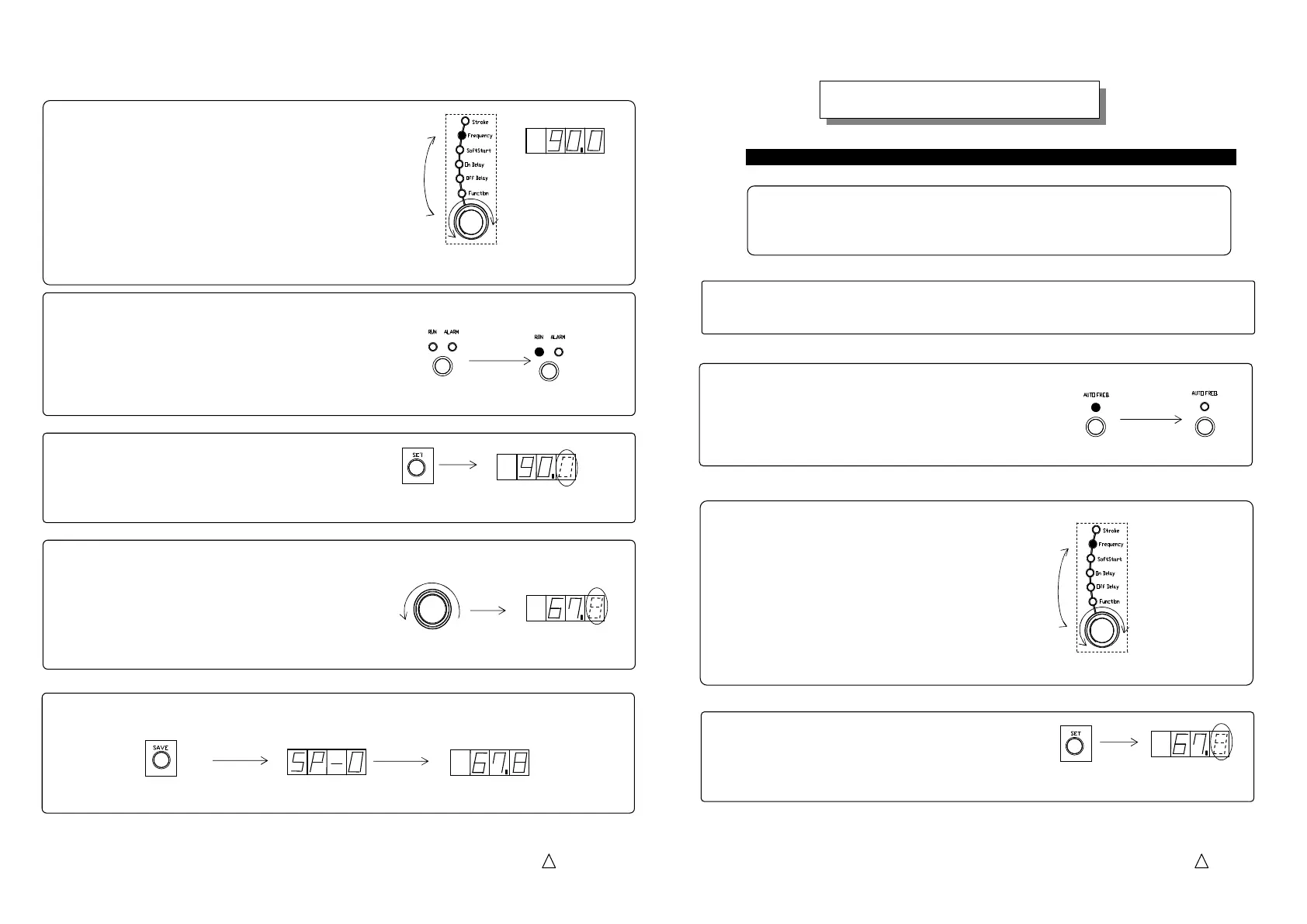

7. Push “Set” button to shift the mode from

“Indication” to “Adjust”.

Blinkin

Push “SET”

8. Dial the Setting Encoder in the counterclockwise to reduce

the drive frequency so that the work pieces are discharged smoothly.

Push “Set” button two times to shift the blinking digit

from decimals to units.

Note: In the case of “Model CF” drive unit the stroke must be set for at the maximum of the unit.

Setting Encoder

Dial

9. When the work pieces are discharged smoothly, push the “Save” button

to store the data having been set.

Push “Save” button

Storing

New data is stored

6. Push “Run/Stop” button and run the partsfeeder or linear feeder.

This example shows the partsfeeder is running at the output

voltage 75 % and drive frequency 90 Hz.

Note: When RUN lamp is blinking

see “Alarm by blinking RUN lamp” on the page 8.

5. Dial “Selection Dial” and select “Frequency”.

Selection Dial

Turning on

Dial

Push Run/Stop

Turning RUN lamp on.

5

HTE302172 20/46

6

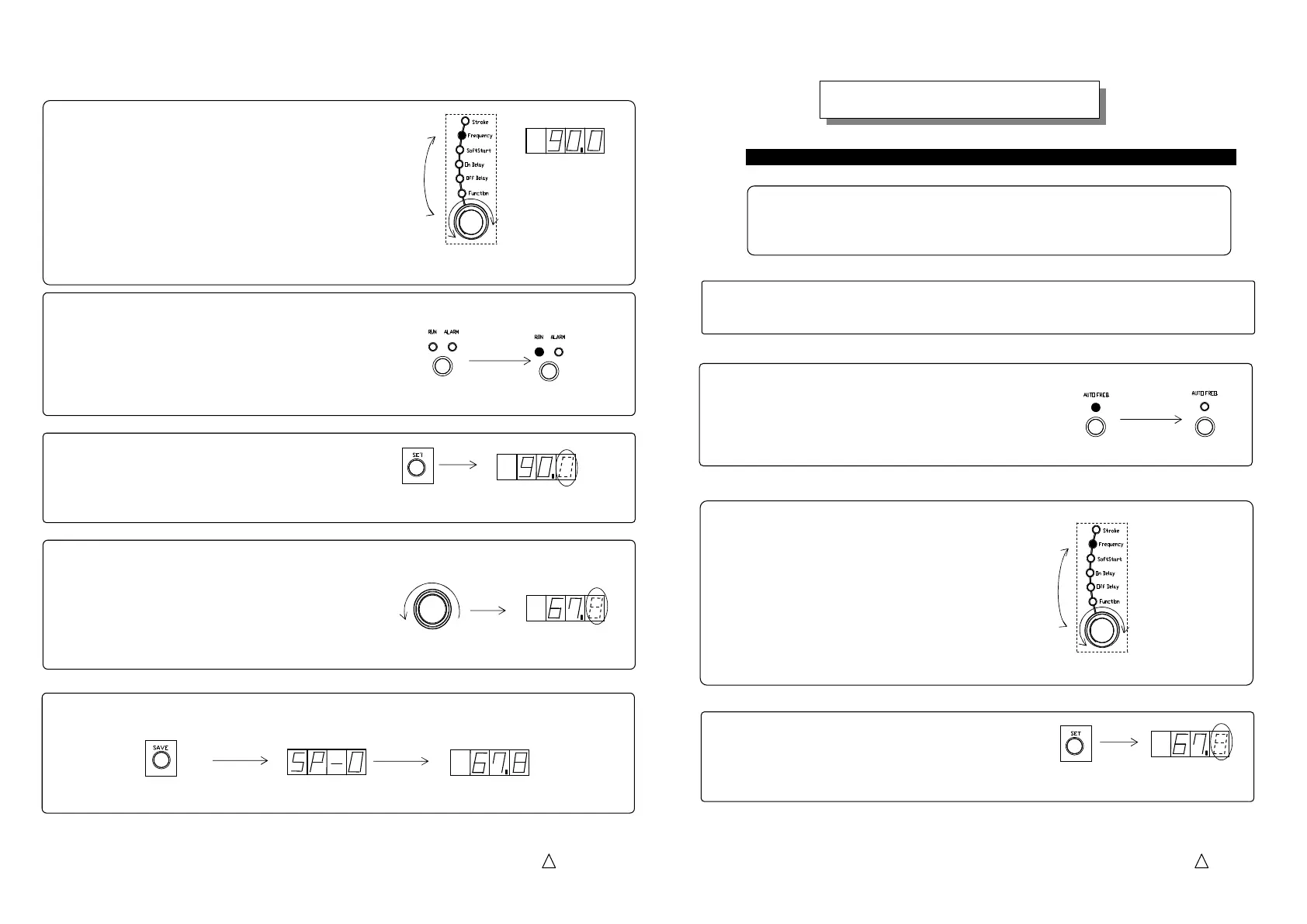

4. Push “Set” button to change the mode from

“Indication” to “Adjustment”.

How to set the Stroke on

How to set the Stroke on How to set the Stroke on

How to set the Stroke on

Constant Stroke mode

Constant Stroke modeConstant Stroke mode

Constant Stroke mode

3. Dial “Selection Dial” to select “Function”.

1. On the beginning, “Stroke” is set on the “Auto-tuning” mode.

See “How to set the stroke on the auto-tuning mode”.

2. Push “Auto Freq” button more than three seconds

and change the mode from auto-tuning to constant stroke.

Push button

AUTO FREQ AUTO FREQ

Selection Dial

Turning on

Dial

Push button

Blinking

After setting the “Frequency Range”, set the stroke following the procedure below.

Put some work pieces in the bowl or chute and set the stroke so that they are discharged

smoothly on the track.

Initial Setting

Initial SettingInitial Setting

Initial Setting

-Continued-

push more than three seconds

Loading...

Loading...