5

HTE302172

39/46

6

First Checking Item

First Checking ItemFirst Checking Item

First Checking Item

Remedy

RemedyRemedy

Remedy

●Does the resonant frequency of the partsfeeder match

the driving frequency range of

C10-controller?

●Review the function setting.

●Readjust the resonant frequency of the drive

unit with leaf springs

●Is the setting of the drive frequency range correct?

●Review the function setting.

●Is the weight of a bowl or chute too heavy for the drive

unit?

●Reduce the weight with a decrease of thickness

of a bowl or chute.

●Adjust the air gap.

●Is there any fault wiring, confusing polarities, the

stroke sensor and

C10-controller?

●Is the air gap out of the standard width?

●Review the wiring plug connector.

●Narrow the air gap of the core and armature of

the drive unit.

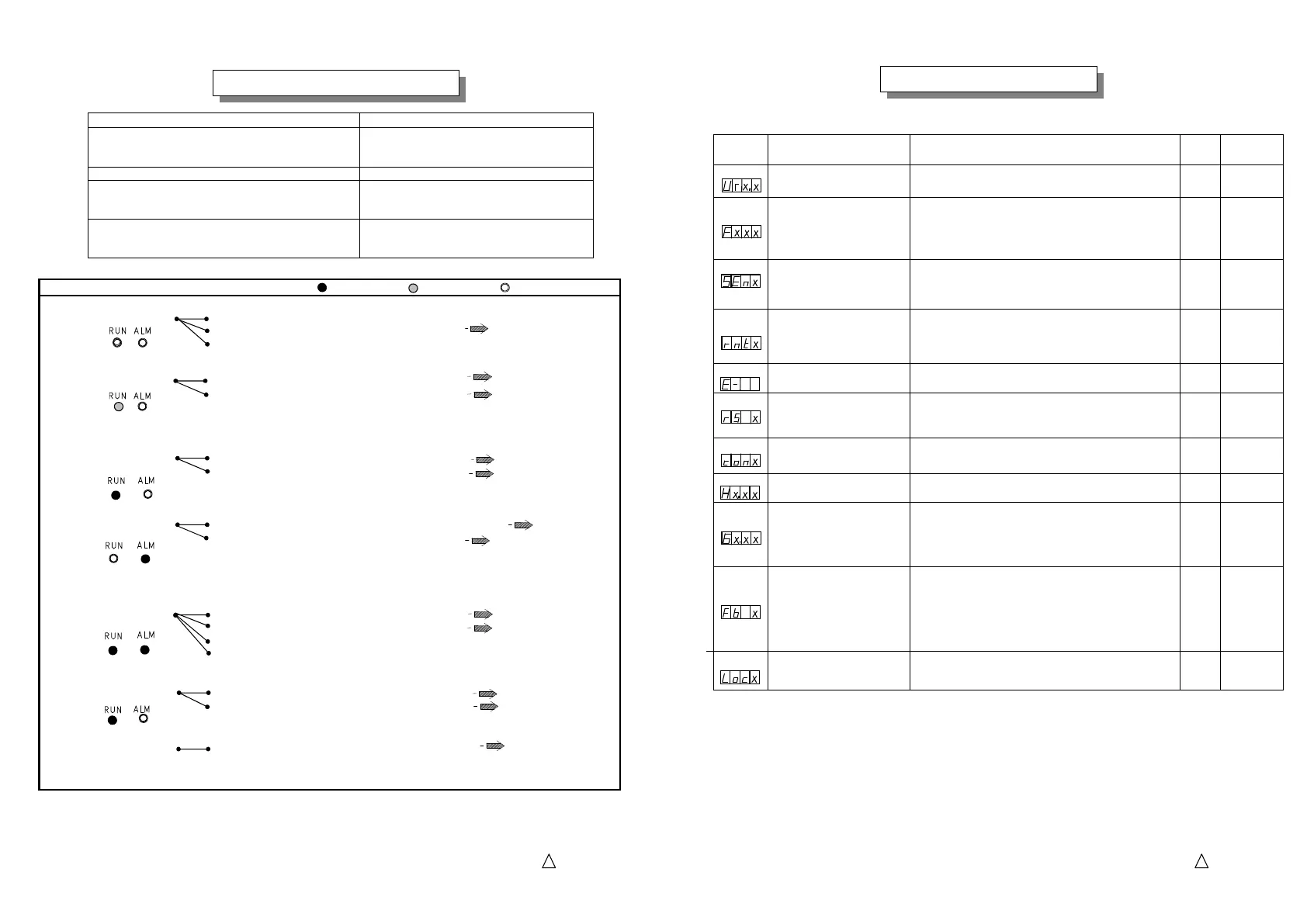

Trouble

TroubleTrouble

Trouble

Checking Item Turning

Checking Item TurningChecking Item Turning

Checking Item Turning

on

onon

on

Biinking

BiinkingBiinking

Biinking

Turning off

Turning off Turning off

Turning off

A. Feeder does not run

1. Fault wiring of power source

2. Low voltage, supply rated voltage

3. Fuse FU1melts down

B. Feeder does not run

1. Stop by the external operation signal

2. Overflow signal is working.

C. Feeder does not run

1. Fault wiring to the feeder/Cable breaks

2. Fault setting of Stroke

D. Feeder does not run

1.

The stroke sensor

is not working, removed or broken lead.

2. Stop by over current protection

2-1. Fault wiring to the feeder/Any short circuit

2-2. Drive frequency range is out of the resonant frequency of the drive unit

2-3. The air gap of the drive unit is too wide

E.

Stroke does not build up

1. Fault setting of Stroke on the panel

2. Too wide air gap of the drive unit

3. Fault function setting for the Stroke Sensor

4. Feeder provides a bowl out of the specification

F. Stroke fluctuates

1. Fault wiring the shield cable and plug connector

2. Loose fitting of the bowl

G.

Memory stores no setting

1. You did not store the data before off the power

See page 29

See Manual of the feeder

See page 25

See page 5

See page 9

See page 26

See page 9

See Manual of the feeder

See page 25

See Manual of the feeder

See page 9

Trouble Shooting

Trouble ShootingTrouble Shooting

Trouble Shooting

See page 6

5

HTE302172

40/46

6

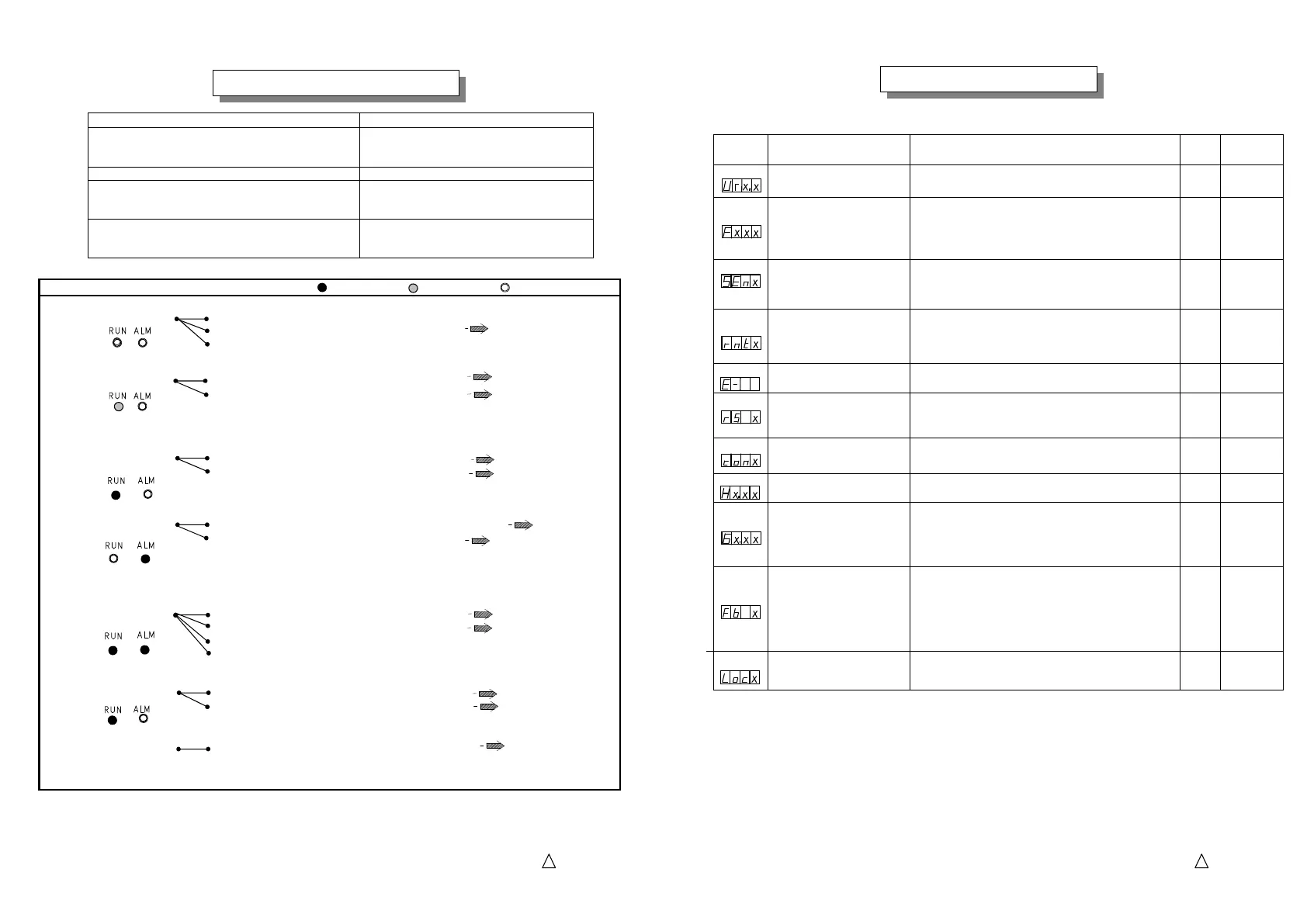

Function

Function Function

Function

Code

CodeCode

Code

Name of Function

Name of FunctionName of Function

Name of Function

Applicable Range

Applicable RangeApplicable Range

Applicable Range

Factory

Factory Factory

Factory

Default

DefaultDefault

Default

Remarks

RemarksRemarks

Remarks

Ur

Information on version

Program Version

Ex.

1.0

See page 11

F

Drive frequency range

90:45 to 90Hz(Half-wave)

180:90 to 180Hz(Full-wave)

360:180 to 360Hz (High-frequency)

120:65 to 120Hz(Middle-frequency)

180 See page 14

Sen

Direction of stroke sensor

0: Reverse phase

1: Synchronous phase

2: Automatic setting

0

See page 28

rnt

Remote

0: Panel operation

1: 4-20 mA current control

2: Two-Rate-of-Feed with two external rheostats

0

See page 30

E-

Error code Error Code of arising error

E-

See page 41

rS

Run/Stop by the Panel mode

0: Running and stopping by RUN/STOP button on the panel

1: Power supply runs the feeder ignoring RUN/STOP

button

1

See page 8

con

“P1”, “P2”

0: “P1” and “P2” is open

1: “P1” and “P2” is close

0

See page 29

H

Scaling of the stroke

Scaling coefficient: 1.00 to 5.00

1.00

See page 22

G

Control Gain

Gain Range: 0.01 to 9.00

On the auto-

tuning and constant stroke mode,

adjusting gain improves responsibility and

stability of soft start and etc.

1.00

See page 21

See page 24

Fb

Feedback Gain

0: Normal

1: Fine

In the case frequency range “F360”

the feedback gain is set for “Fine”

automatically.

0/1 See page 17

Loc

Key Lock

0: Lock off

1: Lock on

0 See page 24

Function Table

Function TableFunction Table

Function Table

Function Table

Function TableFunction Table

Function Table

Loading...

Loading...