5

HTE302172 25/46

6

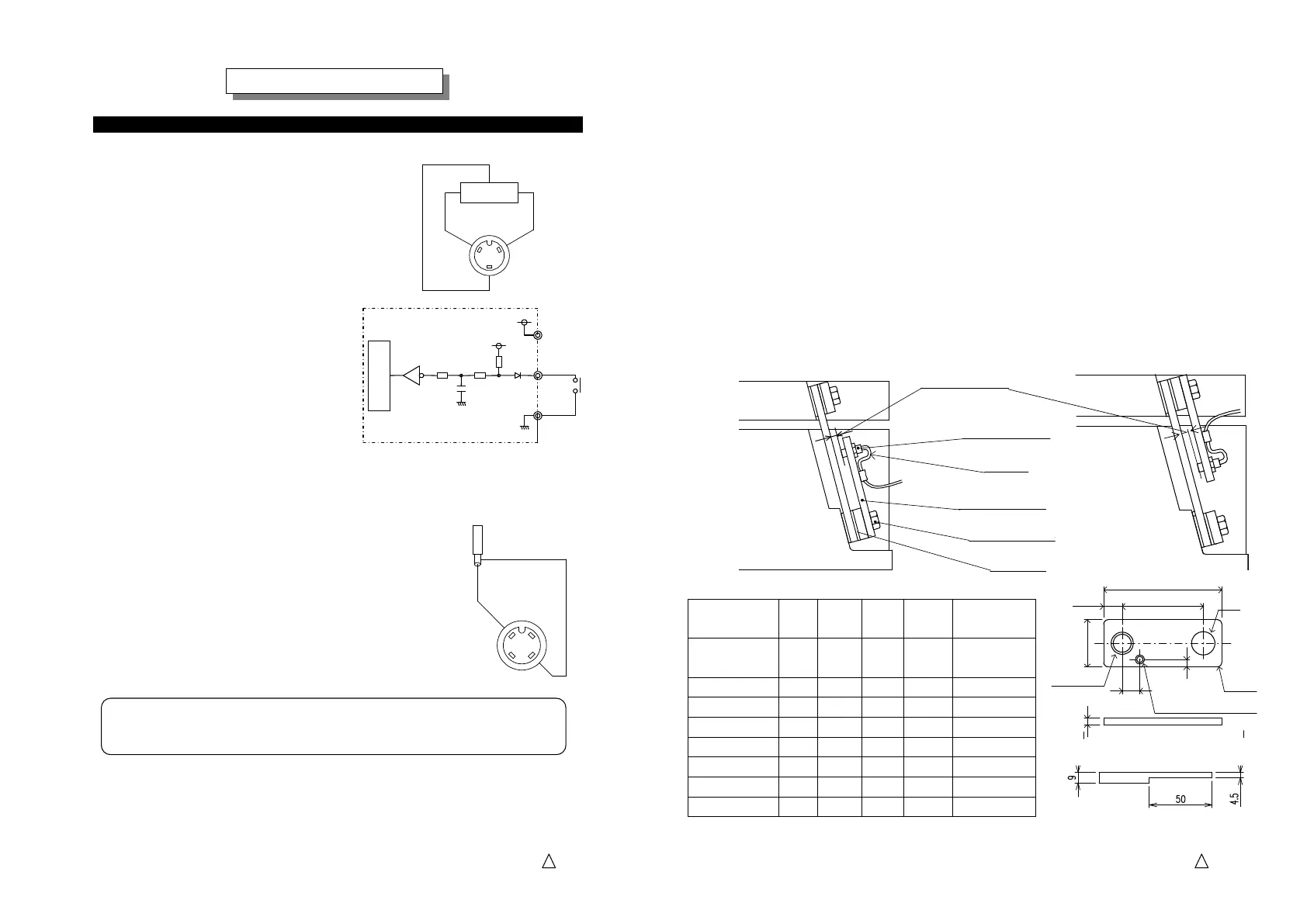

Connection of Overflow Connector

Connection of Overflow Connector Connection of Overflow Connector

Connection of Overflow Connector “

““

“Work Sensor

Work SensorWork Sensor

Work Sensor”

””

”

a. C10-controller provides power supply,

DC 12V and maximum 80 mA, to the Overflow sensor

with a plug and socket connector, three cored, on it.

b. Dry contacts or Open Collector,

maximum sink current 10 mA, is connected

to the No.2 and No. 3 core of

the plug connector controls C10-controller.

When No.2 and No.3 core is closed

the partsfeeder stops. When No.2 and No.3 core

is open the partsfeeder runs.

No.2 and No.3 core is open: On Delay setting

No.2 and No.3 core is closed: Off Delay setting

Note

NoteNote

Note: A proximity switch powered by DC with

two cores can not be used.

Connection of Stroke sensor

Connection of Stroke sensor Connection of Stroke sensor

Connection of Stroke sensor “

““

“PF/LF Sensor

PF/LF SensorPF/LF Sensor

PF/LF Sensor”

””

”

Connection diagram is shown on the right side.

Note

NoteNote

Note: The maximum wiring cable length should be 10m.

When the cable is longer than 10m a shield cable

with an excellent high-frequency characteristic must be used.

+12V 0V

SENSOR

1 3

2

OUT

Caution

CautionCaution

Caution: On the soldering of the cable on the cores of a plug connector,

do not mistake the shield for the core nor the core for the shield.

(

No.2

)

Input

Inner Circuit

(

No.1

)+12V

(

No.3

) 0V

+12V

470Ω

+5V

1

2

Shield

Core lead

Dry contacts or Open Collector

Open:Run

Close:Stop

Connection of Overflow and Stroke sensors

Connection of Overflow and Stroke sensorsConnection of Overflow and Stroke sensors

Connection of Overflow and Stroke sensors

Additional Function

Additional FunctionAdditional Function

Additional Function

-Continued-

5

HTE302172 26/46

6

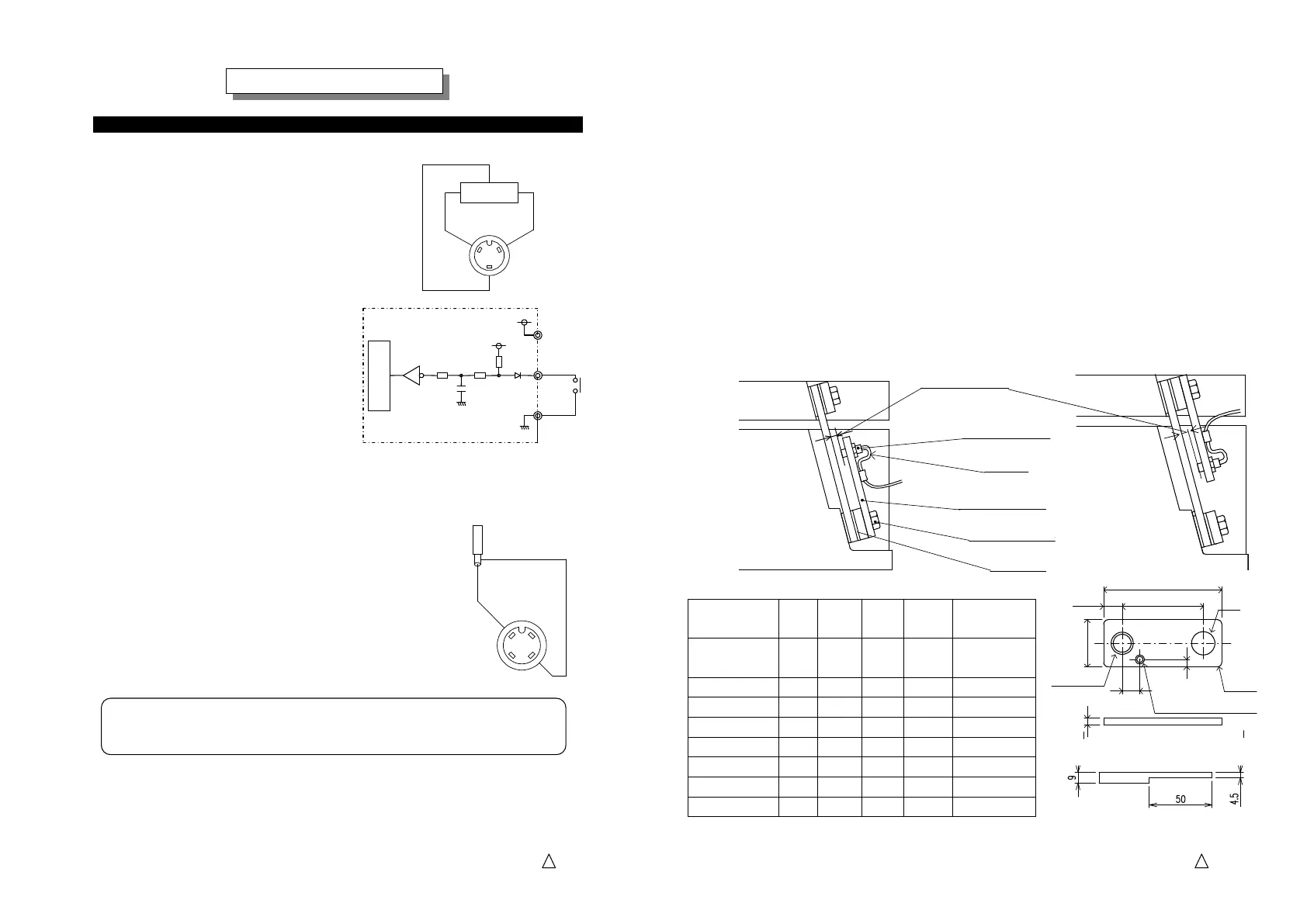

Armature

Base Frame

Mounting of a stroke sensor on a partsfeeder

Mounting of a stroke sensor on a partsfeederMounting of a stroke sensor on a partsfeeder

Mounting of a stroke sensor on a partsfeeder

a.

The stroke sensor must be mounted on in front of a leaf spring with a sensor support.

See the list of the support on the table below that is classified with the model of

the drive unit.

b.

The sensor support is screwed together with the leaf springs with the leaf spring fixing

bolt on the base frame side or bottom without model EA-15 and EA-20.

The supports of model EA-15 and EA-20 must be screwed on the armature or top.

In this case function code “SEn X” must be set for “X=1”. See page 28.

The bolt should be longer than usual by the thickness of the support.

c.

The sensor must be off the leaf spring by 0.5mm and it is called the “air gap”.

d.

Fix the cable with some slack on it to prevent secondary-excited vibration or contact

with any obstacle to break it.

e.

Recommended stroke sensor is: Model EH-110 Proximity sensor by Keyense

Drive Unit W φD L1

L2

Fixing

Direction

EA-15,EA-20

(Previous model)

19 8.5 75 55 Armature

EA-15B 16 7 45 25 Base Frame

EA-20B 19 9 50 30 Base Frame

EA-25,ER-25 19 10.5 80 55 Base Frame

EA-30,ER-30 25 12.5 80 55 Base Frame

EA-38,ER-38 32 16.5 80 55 Base Frame

EA-45,ER-45 32 16.5 80 55 Base Frame

ER-55,65,75 32 16.5 90 60 Base Frame

Size of Sensor support

Spacer

Slack

0.5mm

Air gap

Sensor support

Stroke sensor

Armature

Base Frame

the base frame side

the armature side

See below for ER-55,65,75

M4(

For cable clamp

)

M10 P=1.0

4.5

12

W

L1

L2

4-C1

10

ΦD

Loading...

Loading...