5

HTE302172

27/46

6

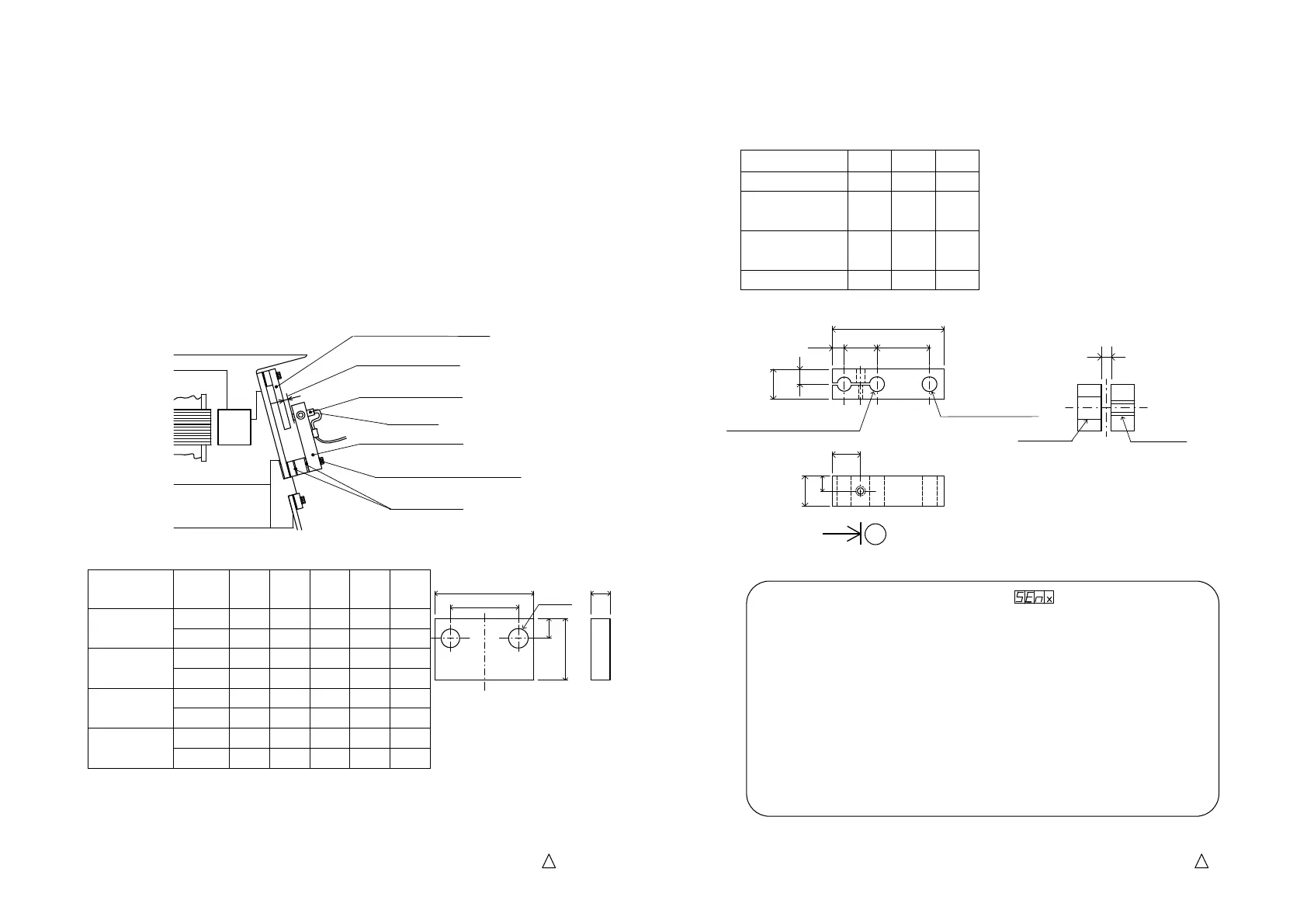

Mounting of Stroke sensor on a linear feeder

Mounting of Stroke sensor on a linear feederMounting of Stroke sensor on a linear feeder

Mounting of Stroke sensor on a linear feeder

a.

Model LFB and DFG series are using leaf springs made of Glass-fiber reinforced plastic

and the proximity sensor does not detect them.

The stainless bar as an object sensed must be mounted on in front of a leaf spring.

The stainless bar is screwed together with the leaf springs with the leaf spring fixing

bolt on the bowl side or top.

b.

The stroke sensor must be mounted on in front of the stainless bar. The sensor support

is screwed together with the leaf springs with the leaf spring fixing bolt on the base

frame side or bottom.

The sensor must be off the bar by 1.0mm and it is called the “air gap”. The width

of the gap changes by the vibration of the drive unit and the change is detected with

the proximity sensor.

The bolt must be longer than usual by the thickness of the support and the bar.

c.

Recommended stroke sensor is “EH-305 Proximity sensor” by Keyense.

d.

Size of the stainless bar / Top and bottom

The table shows model of a linear feeder and the size of the stainless bar.

Drive Unit

Mounted

position

φD

L1

L2

H1

H2

LFB-300

Top 4.5 35 25 15 4

Bottom 4.5 35 25 8 4

LFB-400

LFG-600

Top 5.5 40 28 20 5

Bottom 5.5 40 28 10 5

LFB-550

LFG-750

Top 6.5 45 31 25 6

Bottom

6.5 45 31 12 6

LFG-900

Top 8.5 55 37 30 8

Bottom 8.5 55 37 16 8

6

2-φD

L1

L2

H1

H2

Spacer

Slack

1.0mm

Air gap

Leaf spring fixing bolt

Sensor support

Stroke sensor

Armature

Stainless bar

KEYENCE・・・Model EH-305

5

HTE302172

28/46

6

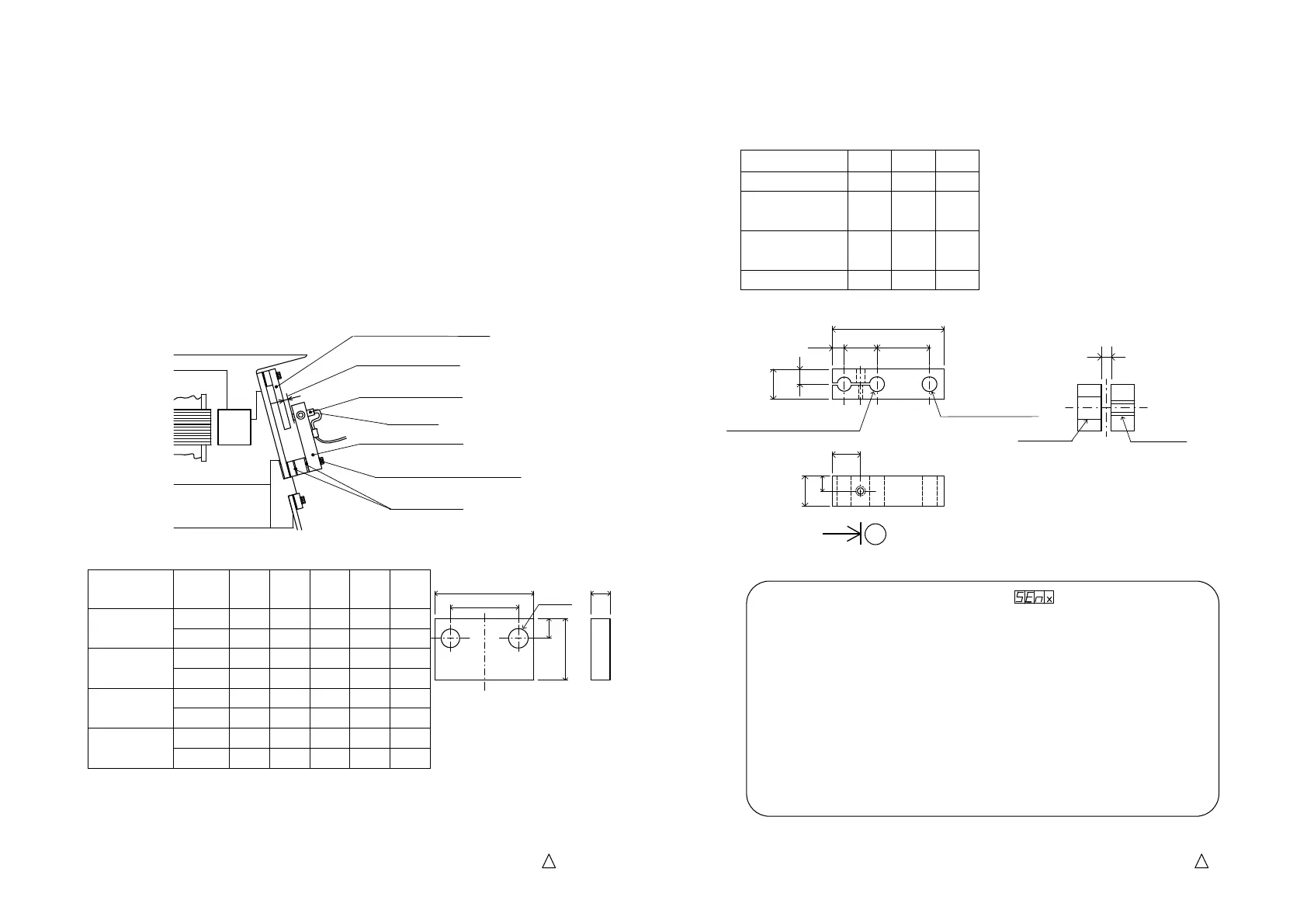

Size of the stainless bar / Top and bottom

Size of the stainless bar / Top and bottomSize of the stainless bar / Top and bottom

Size of the stainless bar / Top and bottom

The table shows model of a linear feeder and the size of the stainless bar.

Drive Unit φD L1 L2

LFB-300 4.5 35 12

LFB-400

LFG-600

5.5 40 17

LFB-550

LFG-750

6.5 45 22

LFG-900 8.5 50 27

Function

Function Function

Function setting

settingsetting

setting

suits for an arrangement of the Stroke Sensor.

suits for an arrangement of the Stroke Sensor.suits for an arrangement of the Stroke Sensor.

suits for an arrangement of the Stroke Sensor.

It is not necessary to set the Function Code according to the phase of

the air gap on the program version 6 or later.

The phase of the air gap is automatically detected when the auto-tuning of

initial setting is completed.

Manual setting is available by setting the Function Code.

Sen0: The phase is reverse. “Reverse” means when the magnet on the drive unit

pulls down the armature the air gap becomes wide.

Sen1: The phase is synchronous. “Synchronous” means when the magnet on the

drive unit pulls down the armature the air gap becomes narrow.

Sen2: Automatically set

9.5

5

10

A

M3

1.0

-

--

-

Section A-

φ3.5

Through hole on one side

L2 12

L1

4

5

10

φD

Through hole

2-φ5.5

Through hole

(Through)Threading on one

Loading...

Loading...