STITCHING

OVER

TWICE

ON

THE

SAME

BUTTONHOLE

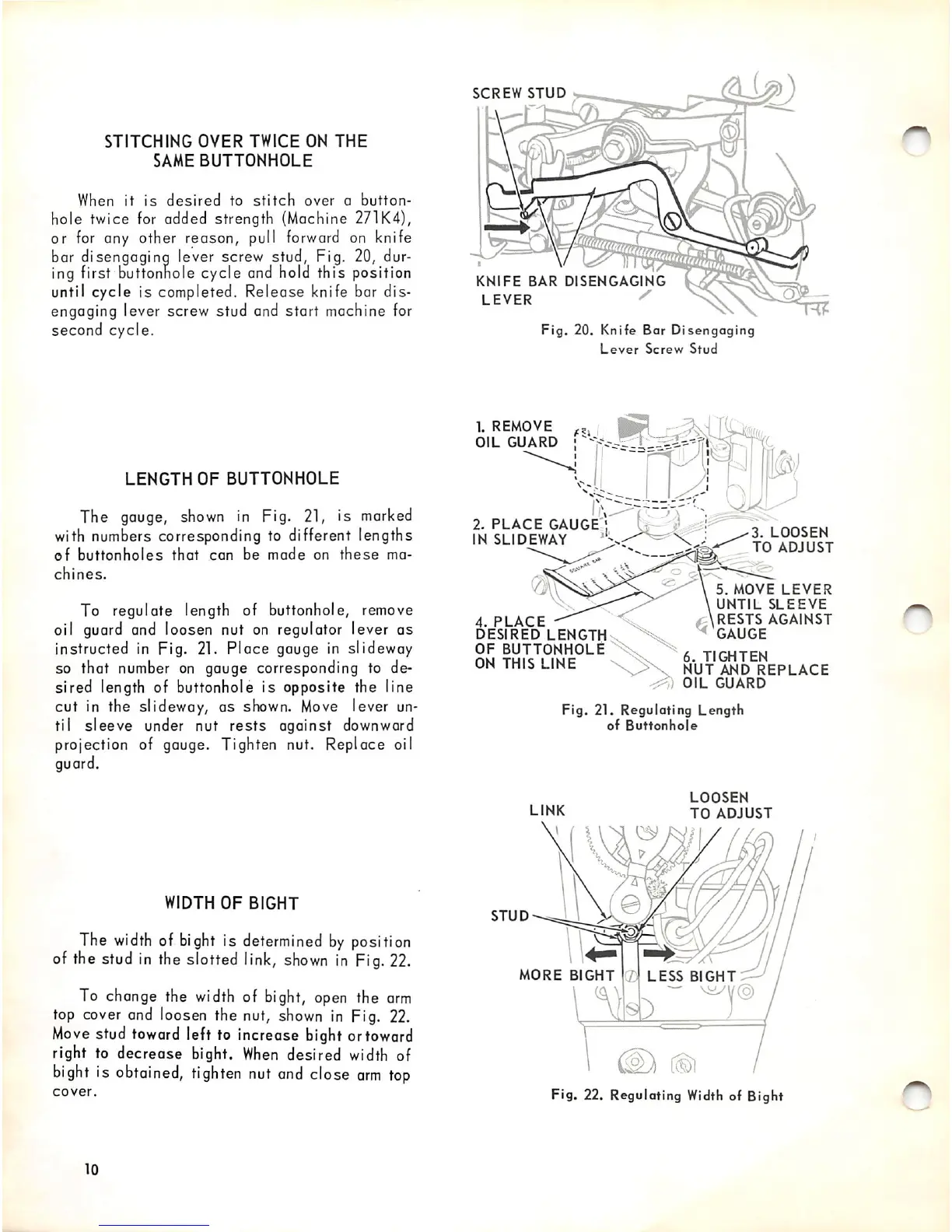

When it

is

desired

to

stitch

over

a

button

hole twice for added strength (Mochine 271K4),

or for any other reason, pull

forward

on knife

bar disengaging lever screw stud, Fig. 20, dur

ing first buttonhole cycle and hold this position

until cycle is completed. Release knife bar dis

engaging lever screw stud and start machine for

second

cycle.

LENGTH

OF

BUTTONHOLE

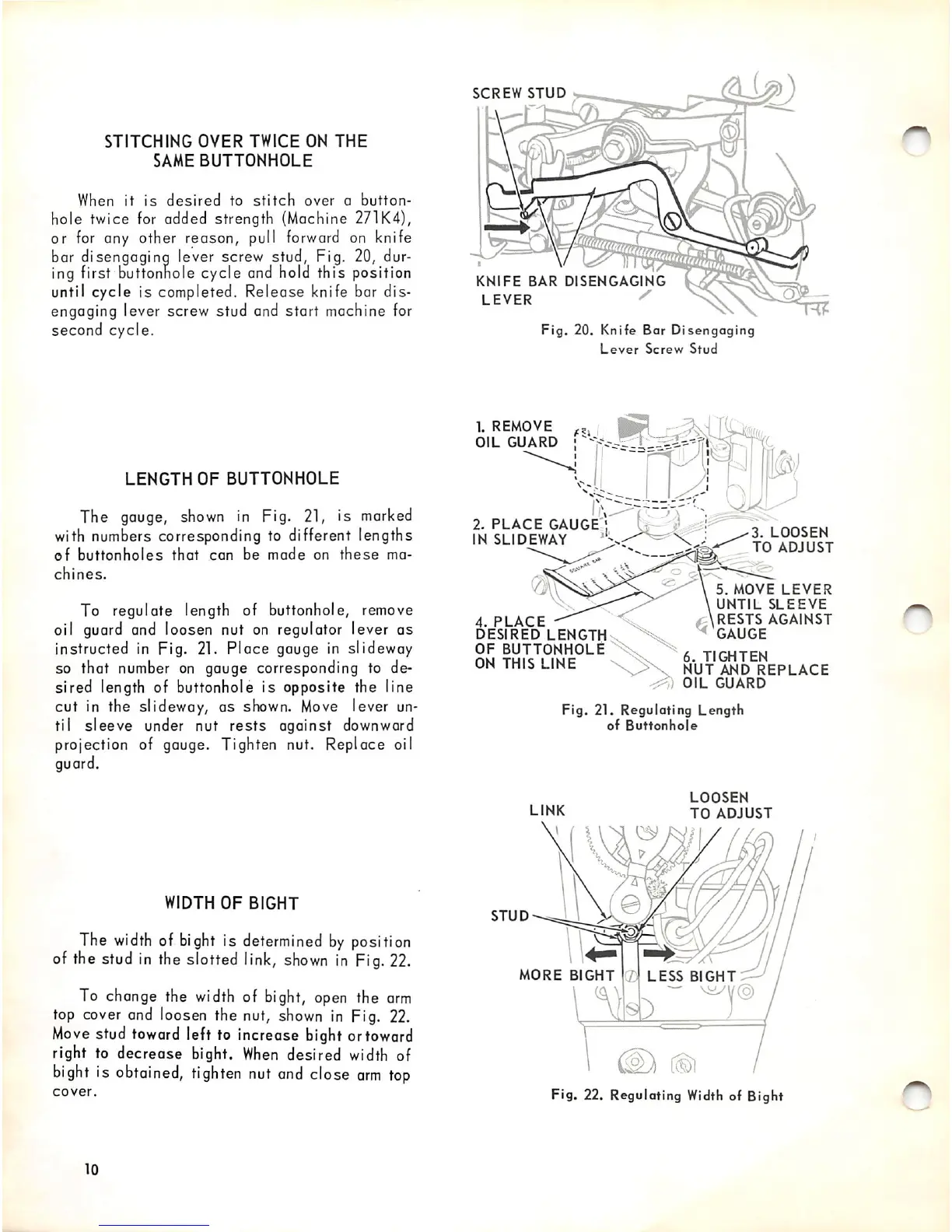

The gauge,

shown

in Fig.

21,

is

marked

with numbers corresponding to different lengths

of

buttonholes

that

con

be

made

on

these

ma

chines.

To regulate length of buttonhole, remove

oil guard and loosen nut on regulator lever as

instructed in Fig. 21.

Place

gauge in slideway

so that number

on

gauge corresponding to de

sired length of buttonhole

is

opposite the line

cut in the slideway, as

shown.

Move

lever

un

til

sleeve

under nut

rests

against downward

projection of gauge. Tighten nut. Replace oil

guard.

WIDTH

OF

BIGHT

The

width

of

bight

is

determined

by

position

of the stud in the slotted

link,

shown

in

Fig.

22.

To change the

width

of bight,

open

the

arm

top

cover

and loosen the nut,

shown

in Fig.

22.

Move

stud

toward

left to increase bight ortoward

right to decrease bight.

When

desired

width

of

bight

is

obtained,

tighten

nut

and

close

arm

top

cover.

10

SCREW

STUD

KNIFE

BAR

DISENGAGING

LEVER

Fig.

20. Knife Bar

Disengaging

Lever

Screw

Stud

1.

REMOVE

OIL

GUARD

2.

PLACE

GAUGE'5

IN

SLIDEWAY

4.

PLACE

DESIRED

LENGTH

OF

BUTTONHOLE

ON

THIS

LINE

^

'3.

LOOSEN

TO

ADJUST

5.

MOVE

LEVER

UNTIL

SLEEVE

RESTS

AGAINST

GAUGE

6.

TIGHTEN

NUT

AND

REPLACE

OIL

GUARD

Fig.

21.

Regulating

Length

of

Buttonhole

STUD

LOOSEN

TO

ADJUST

MORE

BIGHT

'T

LESS

BIGHT

I'M

—

^ ' 1

Fig. 22. Reguloting

Width

of Bight

Loading...

Loading...