THE

CUTTING

SPACE

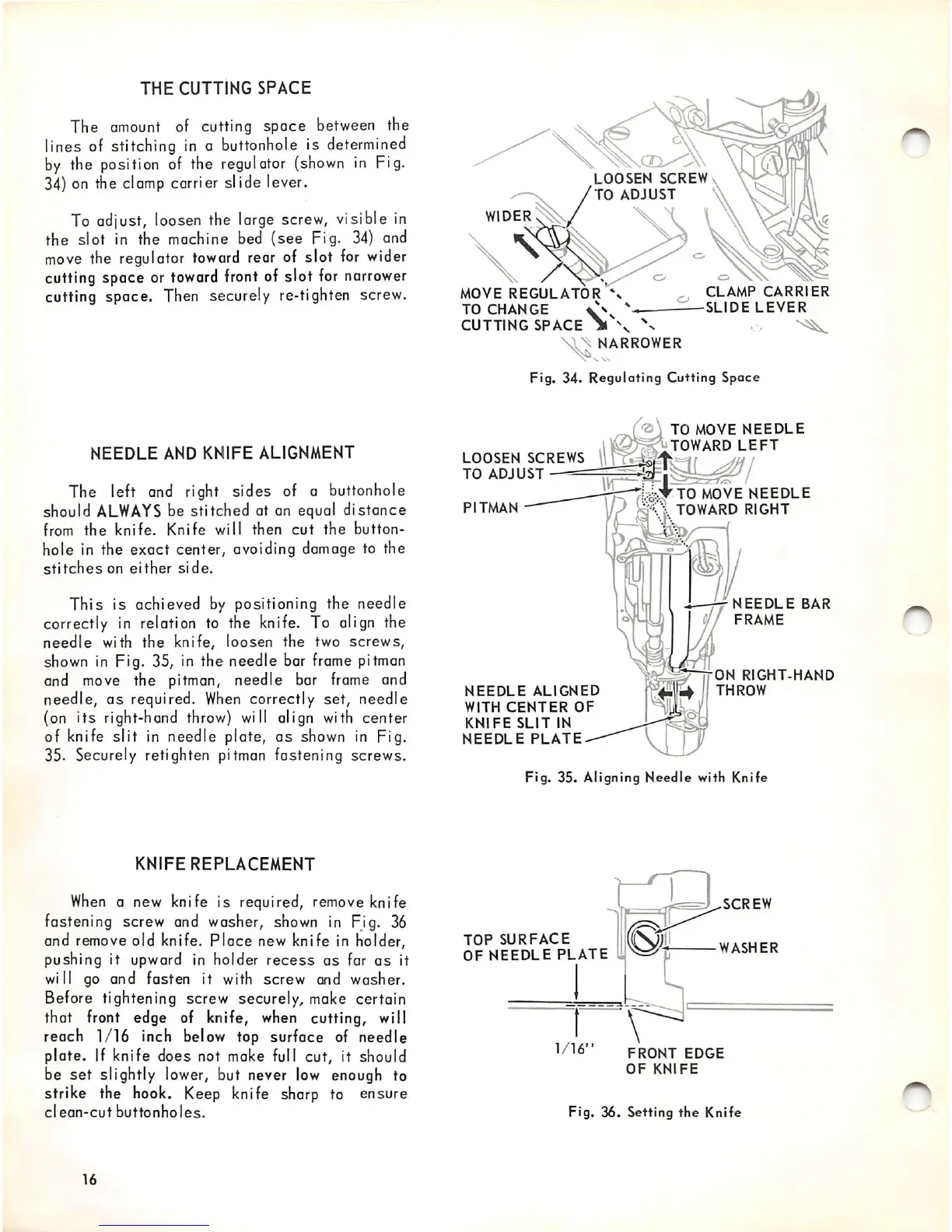

The

amount

of cutting space

between

the

lines of stitching

in

a

buttonhole

is

determined

by

the position of the

regulator

(shown

in

Fig.

34) on the

clomp

carrier slide lever.

To

adjust,

loosen

the large screw, visible

in

the slot in the mochine bed

(see

Fig. 34) and

move

the regulator

toward

rear of slot

for

wider

cutting space or

toward

front

of slot

for

narrower

cutting space. Then securely re-tighten screw.

NEEDLE

AND

KNIFE

ALIGNMENT

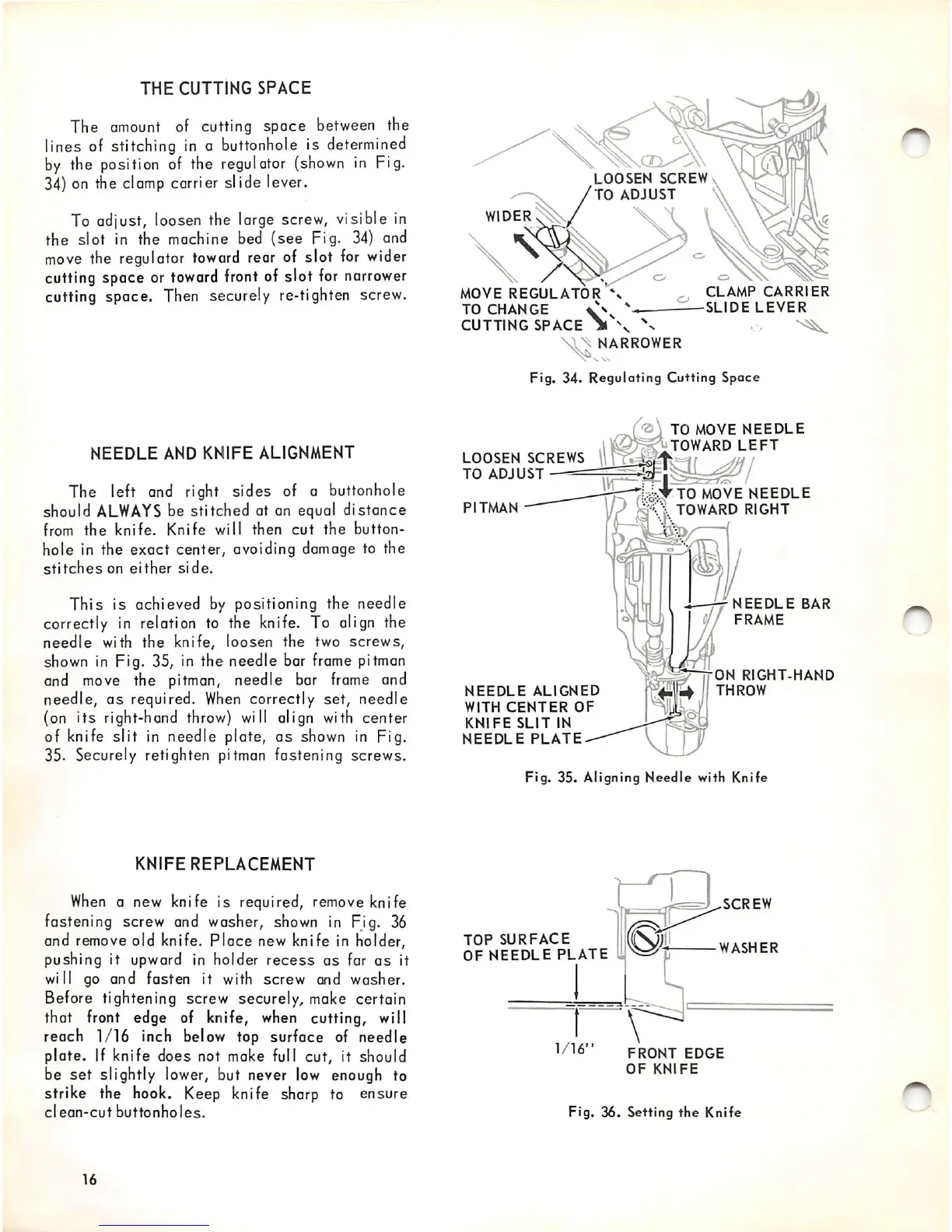

The left and right sides of a buttonhole

should

ALWAYS

be stitched at an equal distance

from

the

knife. Knife will then

cut

the

button

hole in the exact center, avoiding damage to the

stitches

on

either

side.

This is achieved by positioning the needle

correctly in relation to the

knife.

To

align

the

needle

with

the

knife, loosen the two

screws,

shown in Fig. 35, in the needle bar frame pitman

and

move

the pitman, needle bar

frame

and

needle, as required.

When

correctly

set,

needle

(on

its

right-hand throw) will align with center

of knife

slit

in needle plate,

as

shown in Fig.

35. Securely retighten pitman fastening screws.

KNIFE

REPLACEMENT

When

a new knife is required,

remove

knife

fastening screw and washer,

shown

in Fig.

36

and remove old knife.

Place

new knife in holder,

pushing it upward in holder

recess

as for as it

will go and fasten it with screw and washer.

Before tightening screw securely,

moke

certain

that front edge of knife,

when

cutting, will

reach 1/16 inch below top surface of needle

plate. If knife does not moke full cut, it should

be

set

slightly lower, but never low enough to

strike the hook. Keep knife sharp to ensure

clean-cut

buttonholes.

16

WIDER

LOOSEN

SCREW

TO

ADJUST

MOVE

REGULATOR

%

TO

CHANGE

CUTTING

SPACE

- ^

NARROWER

CLAMP

CARRIER

-SLIDE

LEVER

Fig.

34.

Regulating

Cutting Spoce

to

MOVE

NEEDLE

^TOWARD

LEFT

'H

!

LOOSEN

SCREWS

TO

ADJUST

PITMAN

TO

MOVE

NEEDLE

i

TOWARD

RIGHT

NEEDLE

ALIGNED

WITH

CENTER

OF

KNIFE

SLIT

IN

NEEDLE

PLATE

NEEDLE

BAR

!!/

FRAME

ON

RIGHT-HAND

THROW

Fig. 35. Aligning

Needle

with Knife

TOP

SURFACE

OF

NEEDLE

PLATE

1 \

1/16"

front

EDGE

OF

KNIFE

Fig.

36. Setting

the

Knife

SCREW

WASHER

Loading...

Loading...