REGULATING

OIL

FLOW

TO

HOOK

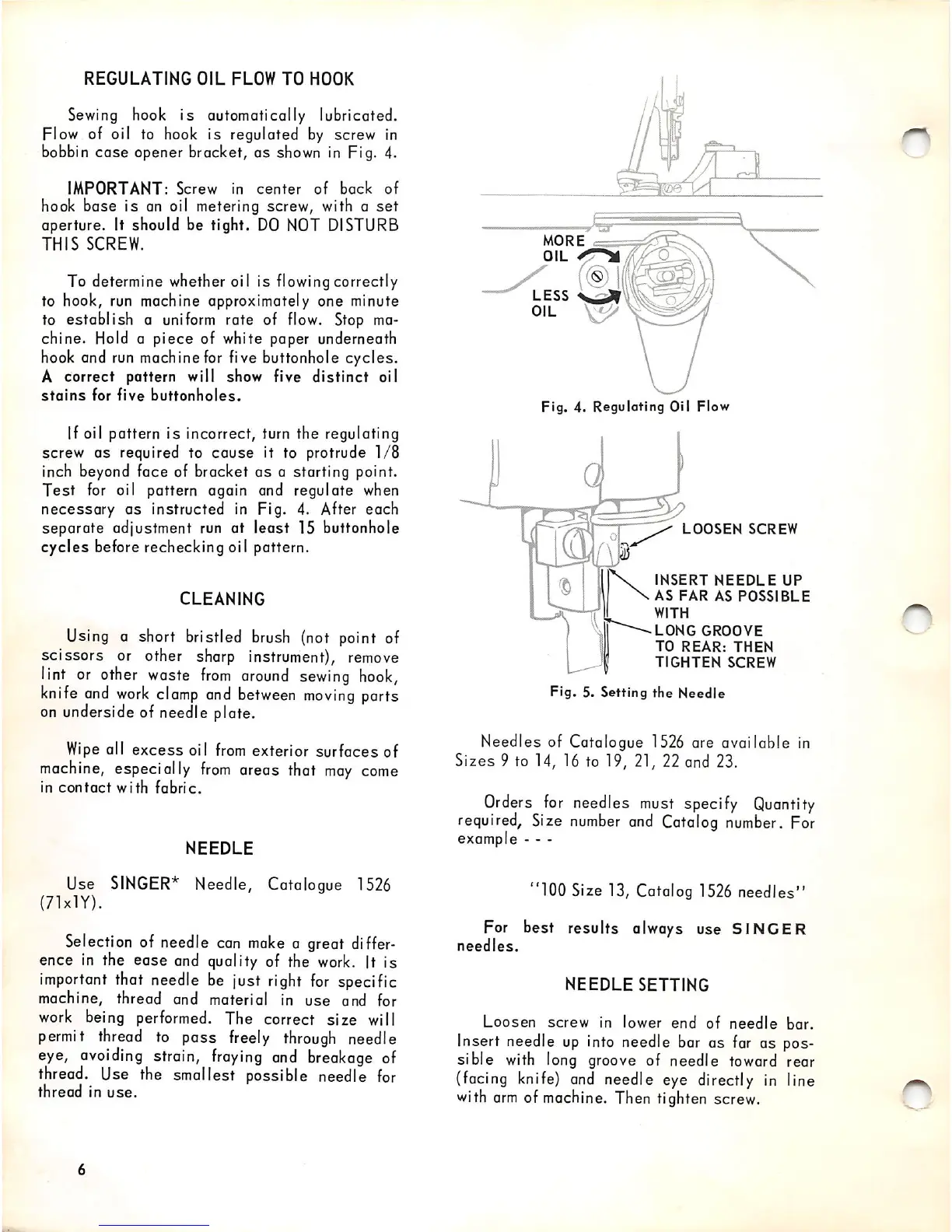

Sewing hook

is

automatically lubricated.

Flow of oil to hook is regulated by screw in

bobbin

case

opener bracket, as shown in Fig. 4.

IMPORTANT:

Screw

in

center

of

back

of

hook base is an oil metering screw, with a

set

aperture. It should be tight.

DO

NOT

DISTURB

THIS

SCREW.

To determine whether oil is flowing correctly

to hook, run machine approximately one minute

to

establish

a uniform rate of flow. Stop ma

chine. Hold a piece of white paper underneath

hook and run machine for five buttonhole cycles.

A correct pattern will show five

distinct

oil

stains

for

five

buttonholes.

If oil pattern is incorrect, turn the regulating

screw

as

required to

cause

it to protrude

1/8

inch beyond face of bracket

as

a starting point.

Test

for oil pattern again and regulate

when

necessary

as

instructed in Fig. 4. After each

separate adjustment run at least 15 buttonhole

cycles

before rechecking oiI pattern.

CLEANING

Using a short bristled brush (not point of

scissors or other sharp instrument),

remove

lint or

other

waste

from

around

sewing

hook,

knife

and

work

clamp

and

between

moving

ports

on underside of needle plate.

Wipe

all

excess

oil

from

exterior

surfaces

of

machine,

especially

from

areas that

may

come

in

contact

with

fabric.

NEEDLE

Use

SINGER*

Needle, Catalogue

1526

(71xlY).

Selection of needle can

make

a great

differ

ence

in

the ease and quality of the

work.

It is

important

that needle be just

right

for

specific

machine, thread and material In

use

and for

work being performed. The correct

size

will

permit

thread

to pass

freely

through

needle

eye,

avoiding

strain,

fraying

and

breakage

of

thread. Use the smallest possible needle

for

thread

in

use.

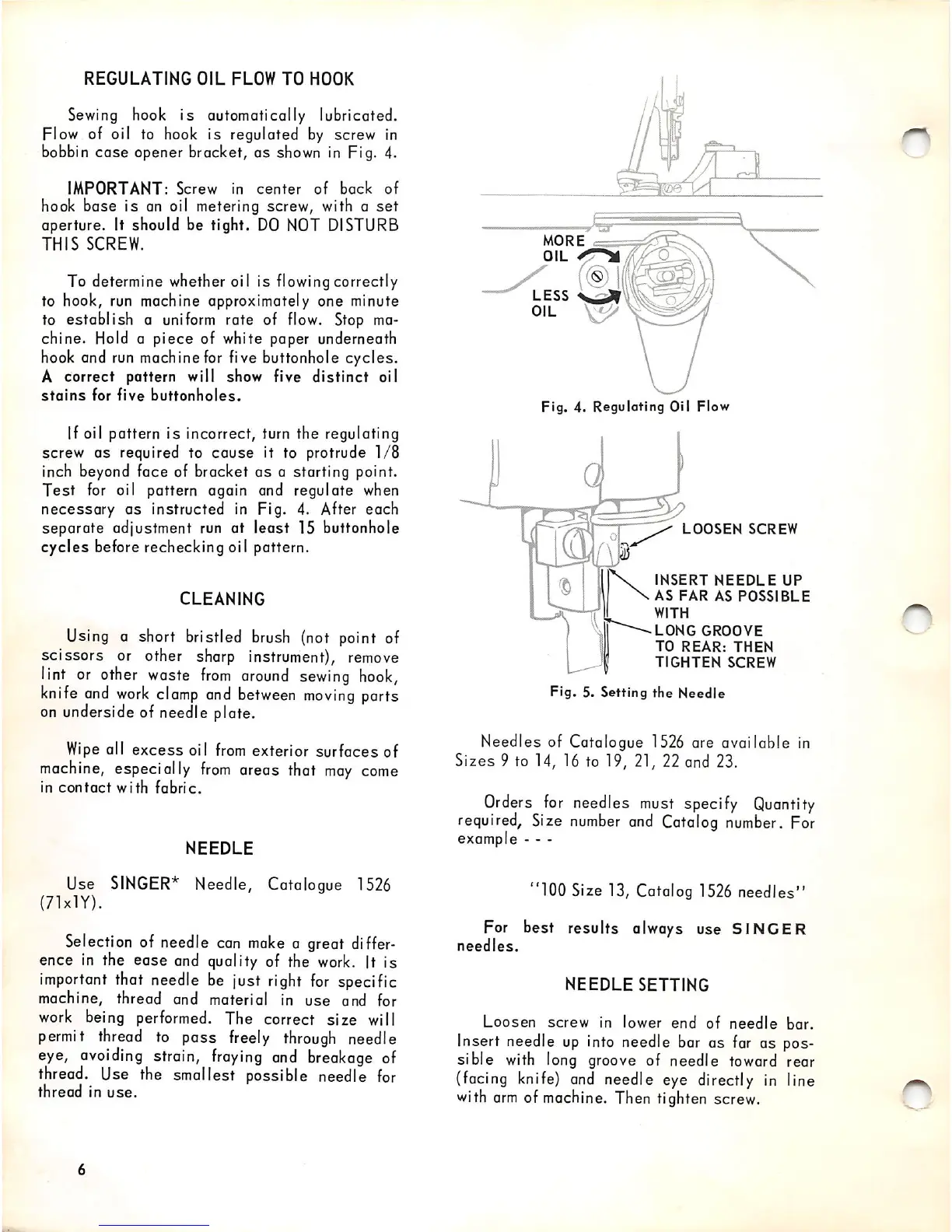

MORE

OIL

ir^sr

Fig. 4. Regulating Oil Flow

LOOSEN

SCREW

INSERT

NEEDLE

UP

AS

FAR

AS

POSSIBLE

WITH

LONG

GROOVE

TO

REAR:

THEN

TIGHTEN

SCREW

Fig.

5.

Setting

the

Needle

Needles of Catalogue 1526 are available in

Sizes 9 to 14, 16 to 19, 21, 22 and 23.

Orders

for

needles

must

specify

Quantity

required.

Size

number

and

Catalog

number.

For

example - - -

"100 Size 13, Catalog

1526

needles"

For best results always use

SINGER

needles.

NEEDLE

SETTING

Loosen

screw

in lower

end

of

needle

bar.

Insert needle

up

into

needle bar as far as pos

sible

with

long groove of needle toward rear

(facing

knife)

and

needle eye directly

in

line

with

arm

of machine. Then tighten screw.

Loading...

Loading...