SEWING

HOOK

(continued)

To time the

hook,

loosen the two sprocket

set

screws, shown in Fig. 82, in the

lower

sprocket for the driving shaft belt. Hold hook so

that

its

point will be in dead center of needle

and

turn

arm

shaft until needle eye is 1/16

inch

below

hook

point

(needle bar rising

on

left

hand

throw).

Tighten

sprocket

set screws

lightly.

Tap

hook

shaft lightly to achieve .002 inch to

.003

inch

end

play

and

securelytighten sprocket

set screws. Recheck and, if necessary, re-time.

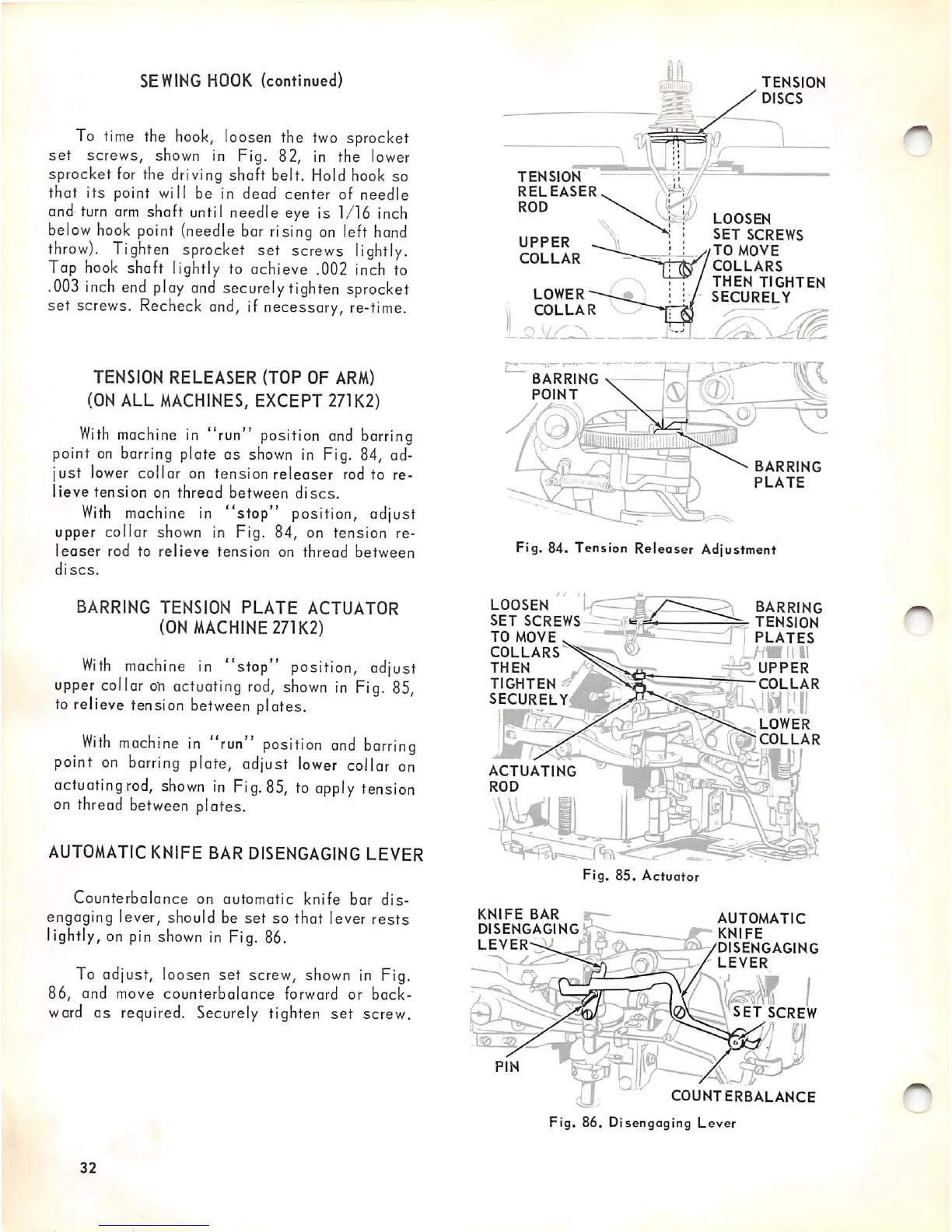

TENSION RELEASER (TOP OF

ARM)

(ON

ALL

MACHINES,

EXCEPT

271K2)

With

machine

in

"run"

position

and

barring

point

on

barring plate as

shown

in Fig. 84, ad

just

lower collar on tension releaser rod to re

lieve

tension

on

thread

between

discs.

With

machine

in

"stop"

position, adjust

upper collar shown in Fig. 84, on tension re-

leaser

rod to

relieve

tension

on

thread

between

discs.

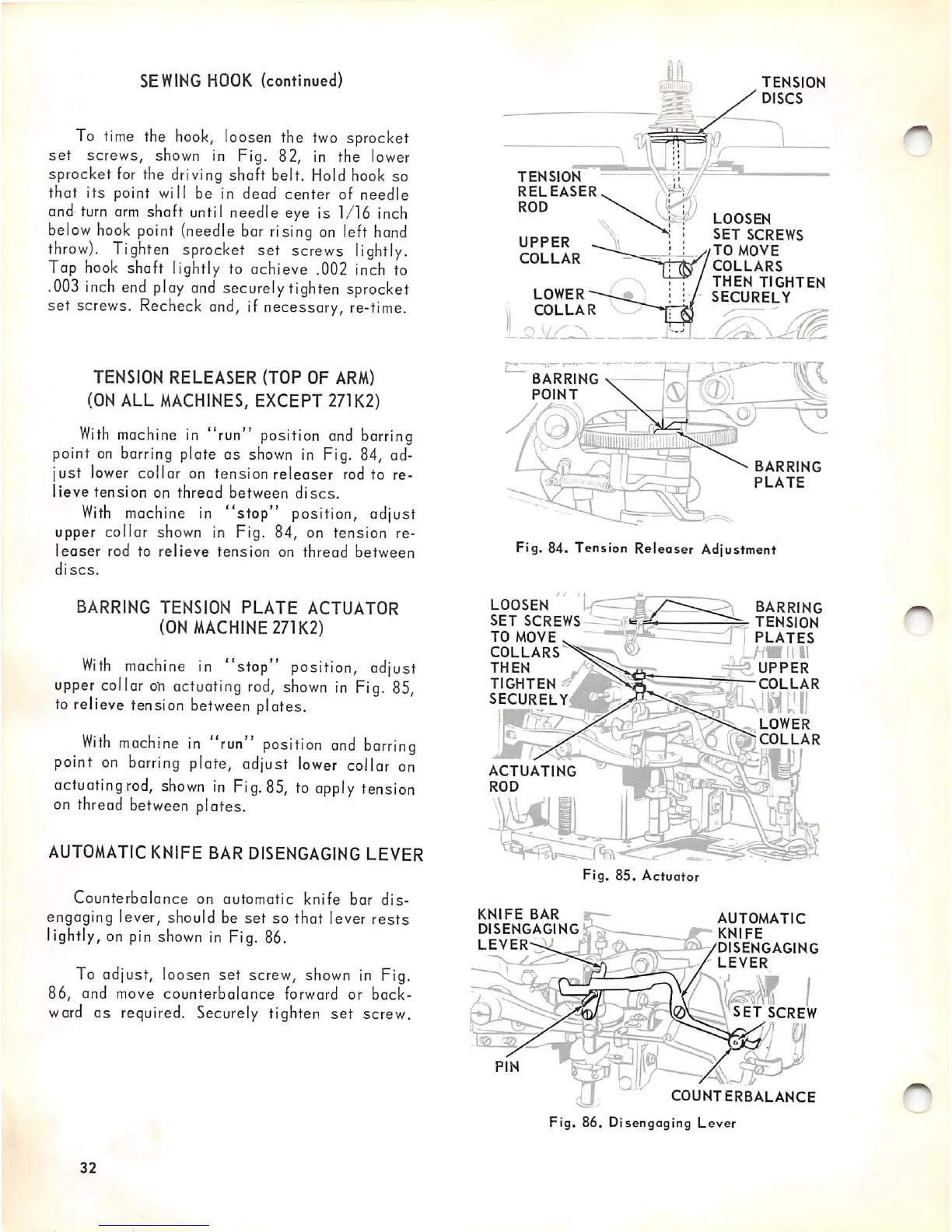

BARRING

TENSION

PLATE

ACTUATOR

(ON

MACHINE

271K2)

With

machine

in

"stop" position, adjust

upper

collar

oti

actuating

rod,

shown

in

Fig.

85,

to relieve tension between plates.

With

machine

in

"run"

position

and

barring

point

on

barring

plate, adjust

lower

collar on

actuatingrod,

shown

in

Fig.

85,

to

apply

tension

on thread

between

plates.

AUTOMATIC

KNIFE BAR

DISENGAGING

LEVER

Counterbalance

on

automatic

knife bar

dis

engaging lever, should be

set

so that lever

rests

lightly,

on

pin

shown

in

Fig.

86.

To adjust, loosen set screw,

shown

in Fig.

86, and move

counterbalance

forward or back

ward as required. Securely tighten

set

screw.

32

TENSION

RELEASER

ROD

UPPER

V

COLLAR

LOWER

COLLAR

BARRING

POINT

TENSION

DISCS

LOOSEN

SET

SCREWS

TO

MOVE

COLLARS

THEN

TIGHTEN

SECURELY

BARRING

PLATE

Fig. 84. Tension Releaser Adjustment

LOOSEN

SET

SCREWS

.fe

TO

MOVE

COLLARS

THEN

TIGHTEN

^ ^

SECURELVii

ACTUATING

ROD

KNIFE

BAR

DISENGAGING

LEVER^^

Fig.

85.

Actuator

barring

TENSION

PIRATES

"

^UPPER

h-COLLAR

LOWER

COLLAR

AUTOMATIC

KNIFE

DISENGAGING

LEVER

^ I

SCREW

COUNTERBALANCE

Fig.

86.

Disengaging

Lever

Loading...

Loading...