MIN.

.015"

CLEARANCE

LOOSEN

LOCK

NUT

TO

ADJUST

TURN

STOP

SCREW

ROD

IN

"STOP"

NOTCH

STARTING

LEVER

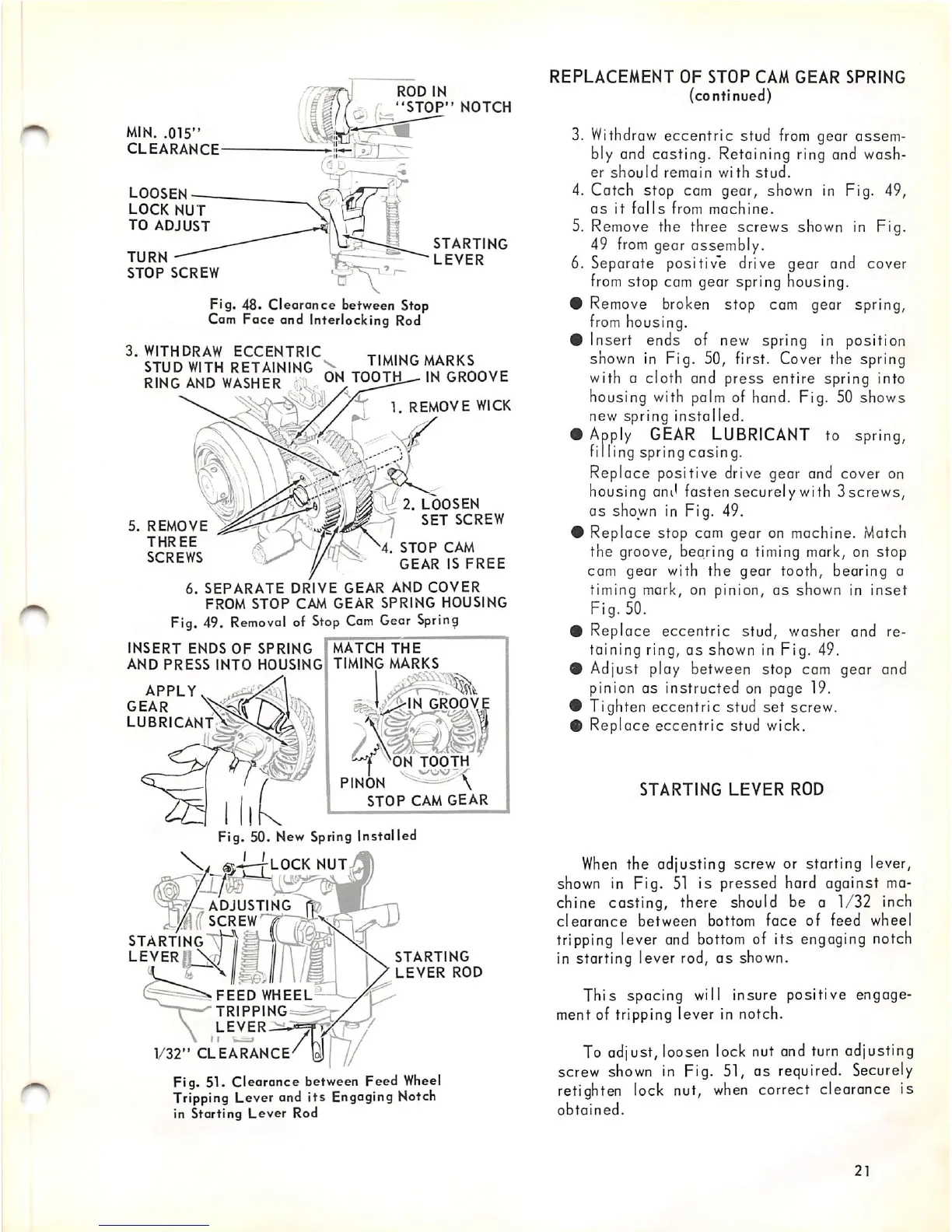

Fig. 48.

Clearance

between Stop

Cam

Face

and Interlocking Rod

3.

WITHDRAW

ECCENTRIC

STUD

WITH

RETAINING

RING

AND

WASHER

.j

V TIMING MARKS

ON

TOOThL-

IN

GROOVE

5.

REMOVE

THREE

SCREWS

1. REMOVE WICK

2.

LOOSEN

SET

SCREW

4.

STOP

CAM

GEAR

IS

FREE

6.

SEPARATE

DRIVE

GEAR

AND

COVER

FROM

STOP

CAM

GEAR

SPRING

HOUSING

Fig. 49.

Removal

of

Stop

Cam

Gear

Spring

INSERT

ENDS

OF

SPRING

AND

PRESS

INTO

HOUSING

APPLY

GEAR

LUBRICANT

MATCH

THE

TIMING

MARKS

1 ;

GROOVE

t^OTH

PINON

STOP

CAM

GEAR

Fig. 50.

New

Spring Installed

V ' I

'•%J

ADJUSTING

_

({

SCREW

STARTING'X)"")^

LEVERIi

Vj

LOCK

NUT.

FEED

WHEEL

TRIPPING

LEVER

V32"

CLEARANCE

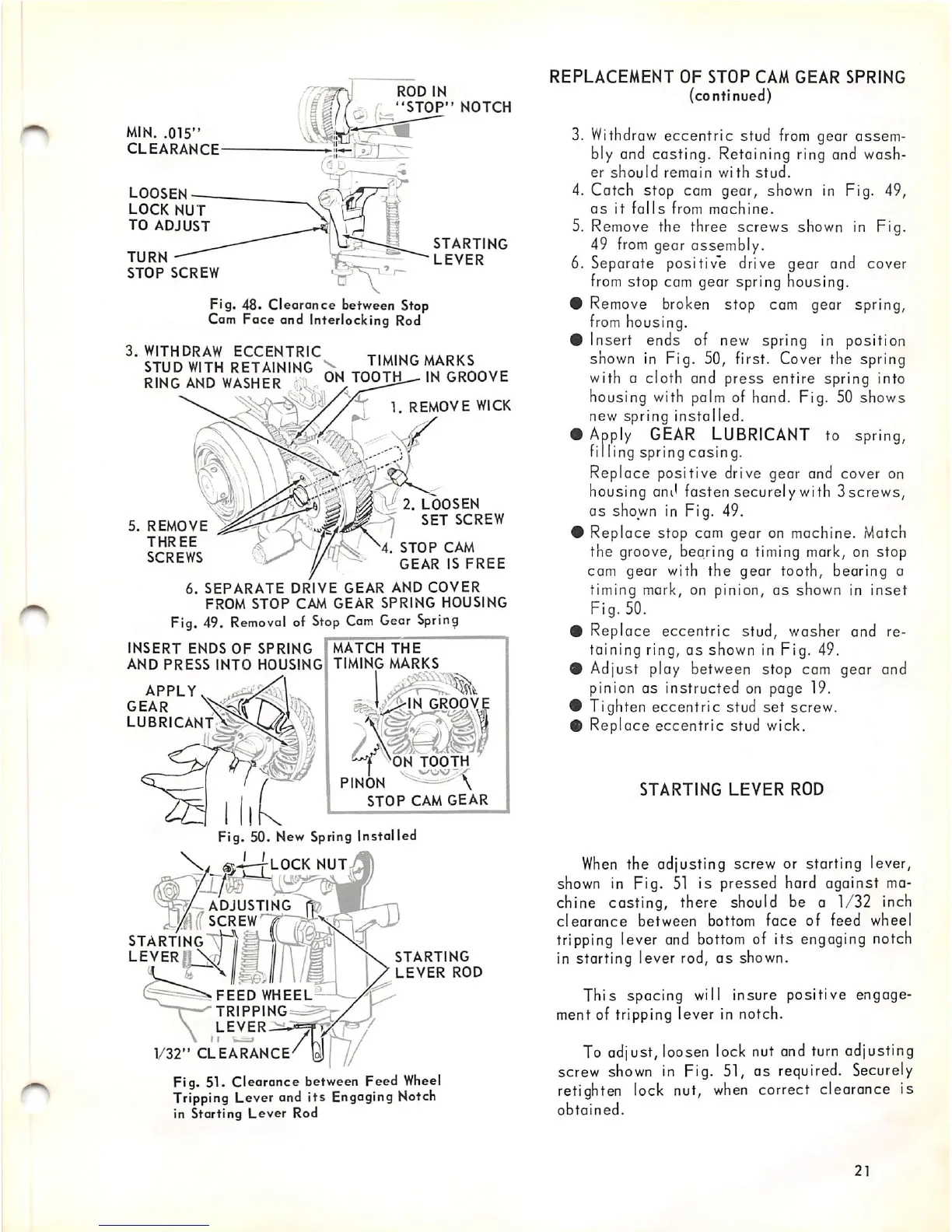

Fig. 51. Clearance between Feed

Wheel

Tripping Lever and

its

Engaging Notch

in Starting

Lever

Rod

STARTING

LEVER

ROD

REPLACEMENT

OF

STOP

CAM

GEAR

SPRING

(continued)

3.

Withdraw

eccentric stud

from

gear assem

bly and casting. Retaining ring and wash

er

should

remain

with

stud.

4. Catch stop cam gear, shown in Fig. 49,

as

it

falls

from

machine.

5. Remove the three screws shown in Fig.

49

from

gear assembly.

6. Separate positive drive gear and cover

from

stop

cam

gear

spring

housing.

#

Remove

broken

stop cam gear spring,

from

housing.

# Insert ends of new spring in position

shown in Fig. 50, first. Cover the spring

with a cloth and press entire spring into

housing with palm of hand. Fig. 50 shows

new spring installed.

0

Apply

GEAR

LUBRICANT

to

spring,

filling

spring

casing.

Replace positive drive gear and cover on

housing and fasten securely with

Sscrews,

as shown in Fig. 49.

• Replace stop cam gear on machine. Match

the groove, bearing a timing mark, on stop

cam gear with the gear tooth, bearing a

timing mark, on pinion,

as

shown in

inset

Fig. 50.

• Replace

eccentric

stud, washer and re

taining ring, as shown in Fig. 49.

# Adjust play between stop cam gear and

pinion as instructed on page 19.

• Tighten

eccentric

stud

set

screw,

0 Replace

eccentric

stud wick.

STARTING

LEVER

ROD

When

the adjusting screw or starting lever,

shown in Fig.

51

is pressed hard against ma

chine casting, there should be a 1/32 inch

clearance

between

bottom

face

of

feed

wheel

tripping lever

and

bottom

of its engaging notch

in starting lever rod,

as

shown.

This

spacing will insure positive engage

ment of tripping lever in notch.

To adjust, loosen lock nut and

turn

adjusting

screw

shown

in Fig. 51, as required.

Securely

retighten lock nut,

when

correct clearance is

obtained.

21

Loading...

Loading...