angular

cut

r

Jj

MUST

NOT

BREAK

^

/V\

into

TAPPED

HOL^

/

C

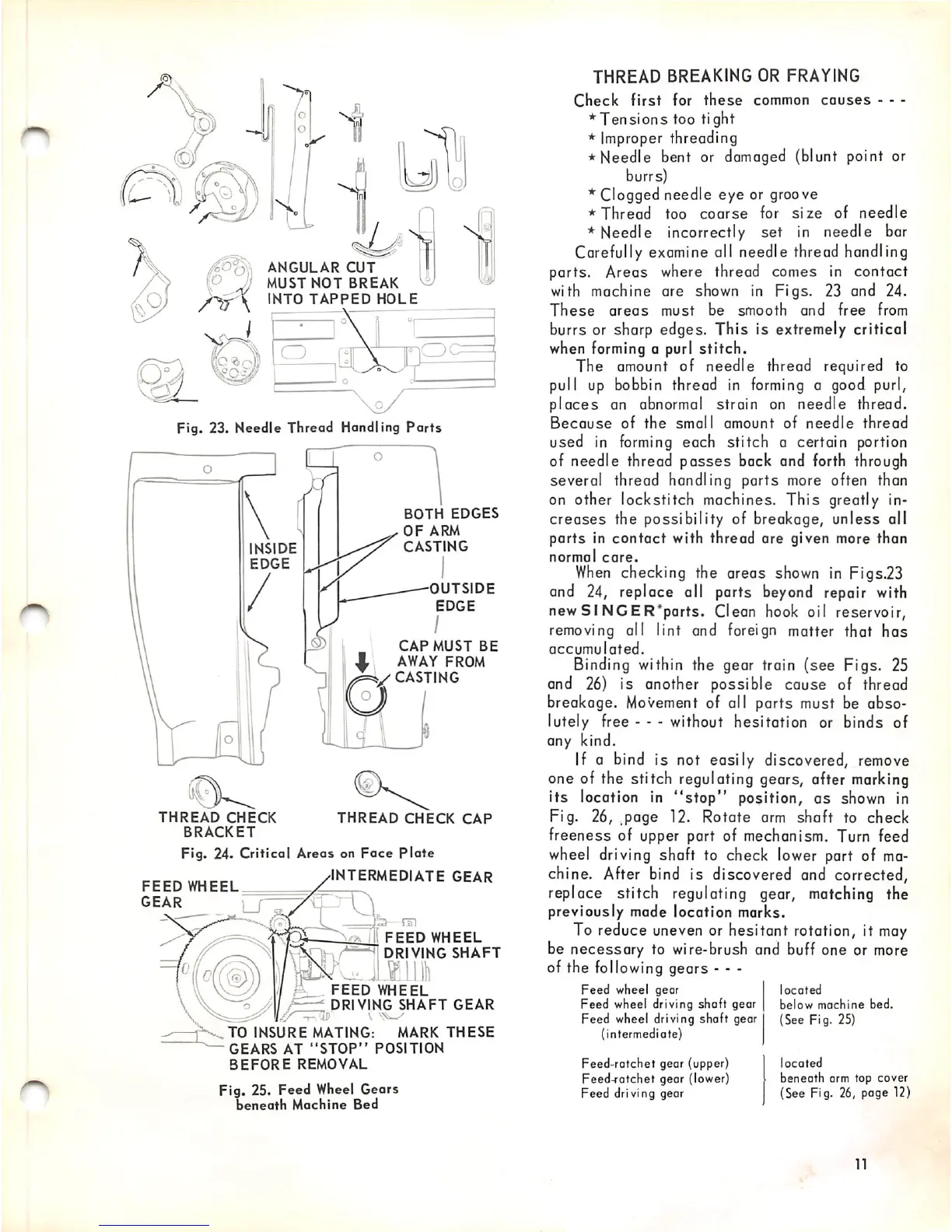

Fig. 23. Needle Thread Handling

Parts

CT

INSIDE

EDGE

THREAD

CHECK

BRACKET

BOTH

EDGES

OF

ARM

CASTING

I

OUTSIDE

EDGE

/

CAP

MUST

BE

X

AWAY

FROM

CASTING

O

"*

THREAD

CHECK

CAP

Fig.

24.

Critical

Areas on

Face

Plate

INTERMEDIATE

GEAR

FEED

WHEEL

GEAR

13-

rm

FEED

WHEEL

DRIVING

SHAFT

!Jih

FEED

WHEEL

DRIVING

SHAFT

GEAR

\

'N-

•

TO

INSURE

MATING;

MARK

THESE

-GEARS

AT

"STOP"

POSITION

BEFORE

REMOVAL

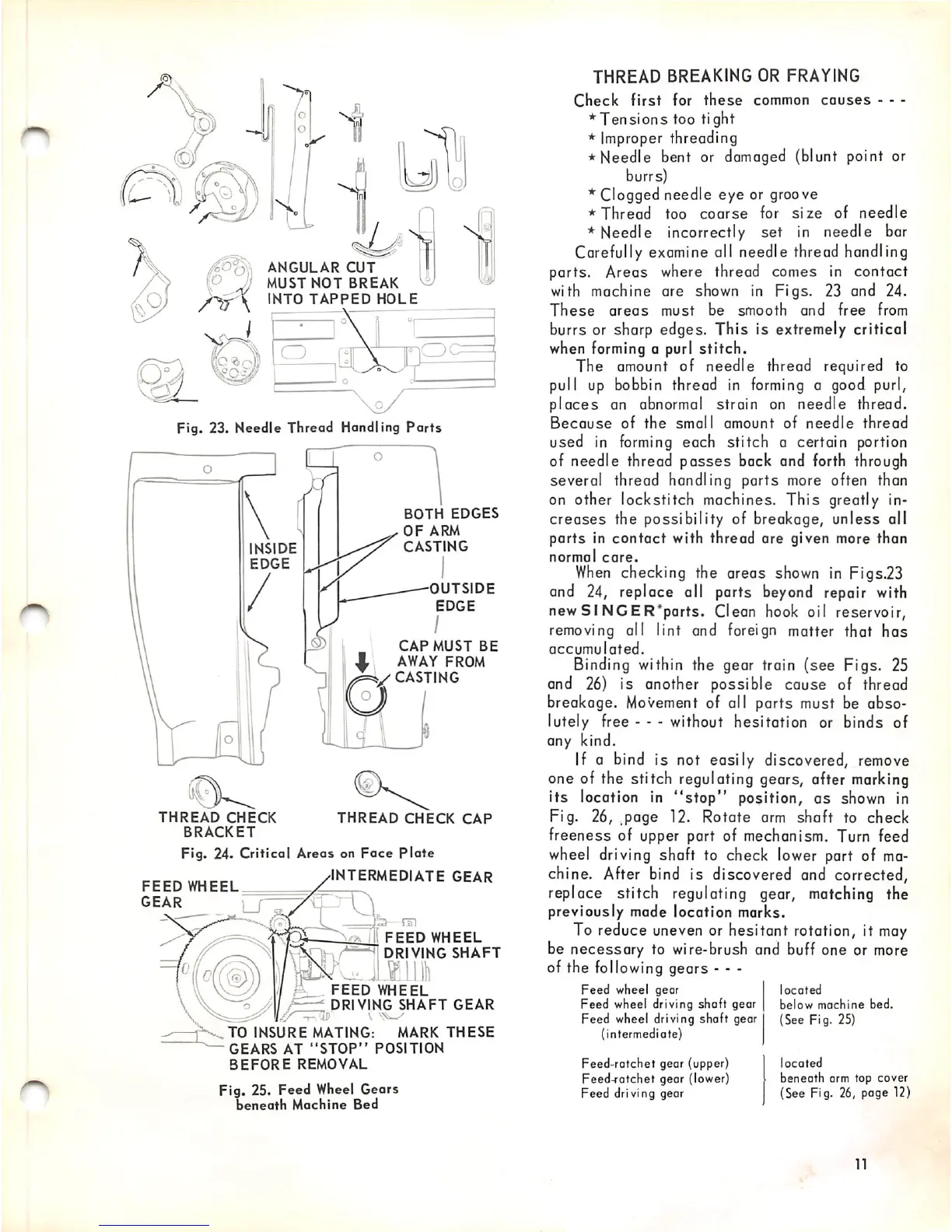

Fig. 25. Feed Wheel Gears

beneath

Machine

Bed

THREAD BREAKING OR FRAYING

Check

first

for

these

common

causes

- - -

*Tensions

too tight

* Improper threading

* Needle bent or damaged (blunt point or

burrs)

* Clogged needle

eye

or groove

★Thread

too

coarse

for

size

of

needle

* Needle incorrectly set in needle bar

Carefully examine all needle thread handling

parts. Areas where thread comes in contact

with machine are shown in Figs. 23 and 24.

These

areas

must

be

smooth

and

free

from

burrs or sharp edges. This is extremely critical

when

forming

a purl stitch.

The amount of needle thread required to

pull up bobbin thread in

forming

a good purl,

places

an abnormal strain on needle thread.

Because

of

the

small

amount

of

needle

thread

used in

forming

each stitch a certain portion

of needle thread

passes

bock and forth through

several thread handling parts more often than

on other lockstitch machines. This greatly in

creases

the

possibility

of breakage,

unless

oil

parts in contact with thread are given more than

normal

core.

When

checking the areas

shown

in Figs.23

and 24, replace all parts

beyond

repair with

new

Si

NC ER*parts. Clean hook oil reservoir,

removing all lint and foreign matter that

has

accumulated.

Binding within the gear train (see Figs. 25

and

26)

is another possible cause of thread

breakoge.

Movement

of oil parts must be abso

lutely

free---

without hesitation or binds of

any kind.

If a bind is not easily discovered,

remove

one of the stitch regulating gears, after

marking

its location in

"stop"

position, as

shown

in

Fig. 26, .page 12. Rotate arm shaft to check

freeness of upper port of mechanism. Turn feed

wheel driving shaft to check lower part of

ma

chine. After bind is discovered and corrected,

replace stitch regulating gear,

matching

the

previously made location marks.

To reduce uneven or hesitant rotation, it

may

be necessary to wire-brush and buff one or more

of the following gears - - •

Feed

wheel geor

Feed wheel driving shaft geor

Feed wheel driving shaft gear

(intermediote)

Feed-ratchet geor (upper)

Feed-rotchet gear (lower)

Feed

driving geor

located

belaw

machine

bed.

(See Fig. 25)

located

beneath orm top cover

(See Fig. 26, page 12)

11

Loading...

Loading...