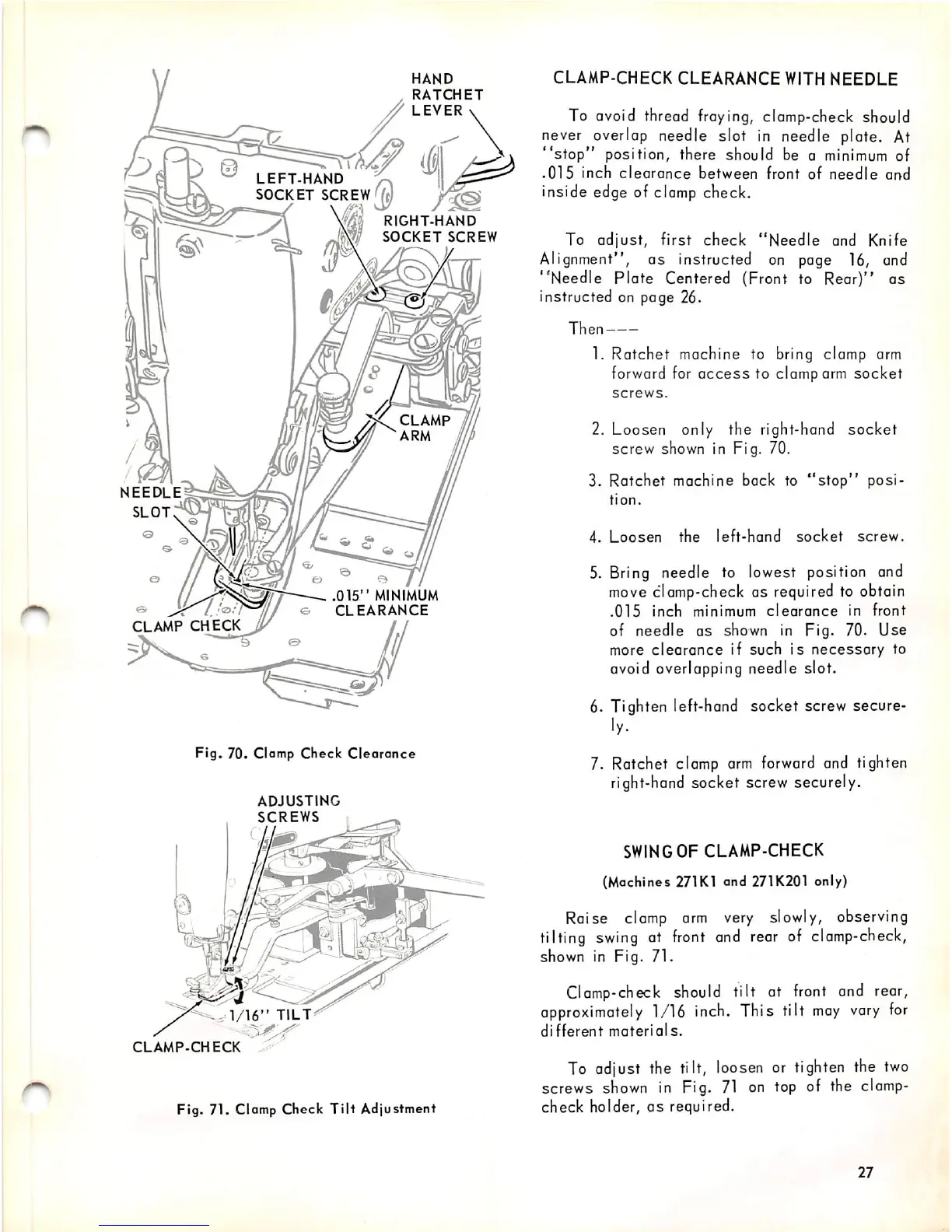

NEEDLE

SLOT

CLAMP

CHECK

LEFT-HAND

SOCKET

SCREW^

RIGHT-HAND

SOCKET

SCREW

HAND

RATCHET

LEVER

^ 'I

CLAMP

ARM

j.

.015"

MINIMUM

e

CLEARANCE

Fig.

70. Clamp

Check

Clearance

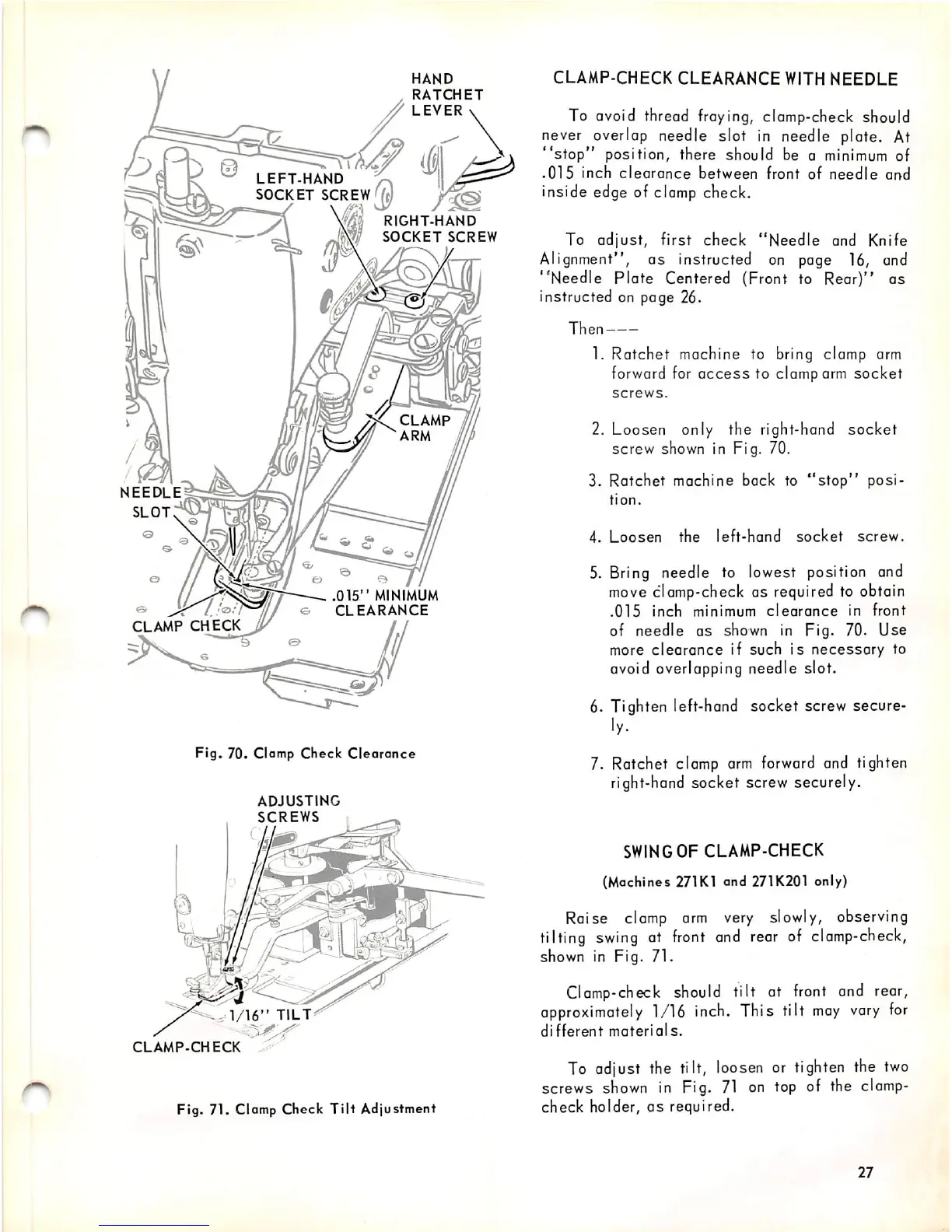

ADJUSTING

SCREWS

1/16"

TILT

CLAMP-CHECK

Fig. 71. Clamp Check Tilt Adjustment

CLAMP-CHECK

CLEARANCE

WITH

NEEDLE

To avoid thread fraying, ciamp-check should

never overlap needle slot in needle plate. At

"stop"

position, there should be a

minimum

of

.015

inch

clearance

between

front of

needle

and

inside edge of clamp check.

To

adjust,

first

check

"Needle

and Knife

Alignment", as instructed on page 16, and

"Needle

Plate

Centered (Front to Rear)" as

instructed on page 26.

Then

1. Ratchet machine to bring clamp arm

forward for

access

to clamp arm

socket

screws.

2. Loosen only the right-hand

socket

screw shown in Fig. 70.

3. Ratchet machine bock to

"stop"

posi

tion.

4.

Loosen

the

left-hand

socket

screw.

5.

Bring

needle to lowest position and

move clamp-check as required to obtain

.015

inch

minimum

clearance

in

front

of needle as shown in Fig. 70. Use

more

clearance

if such

is

necessary

to

avoid overlapping needle slot.

6. Tighten left-hand socket screw secure-

ly.

7. Ratchet clamp

arm

forward

and tighten

right-hand socket screw securely.

SWING

OF CLAMP-CHECK

(Machines 271K1 and271K2Q1 only)

Raise

clamp

arm

very

slowly, observing

tilting

swing

at

front

and

rear

of

clamp-check,

shown in Fig. 71.

Clamp-check should tilt at front and rear,

approximately

1/16 inch. This tilt

may

vary

for

different

materials.

To

adjust the tilt,

loosen

or

tighten

the

two

screws

shown

in Fig.

71

on

top of the

clamp-

check holder,

as

required.

27

Loading...

Loading...