FEED

WHEEL

TRIPPING

POINTS

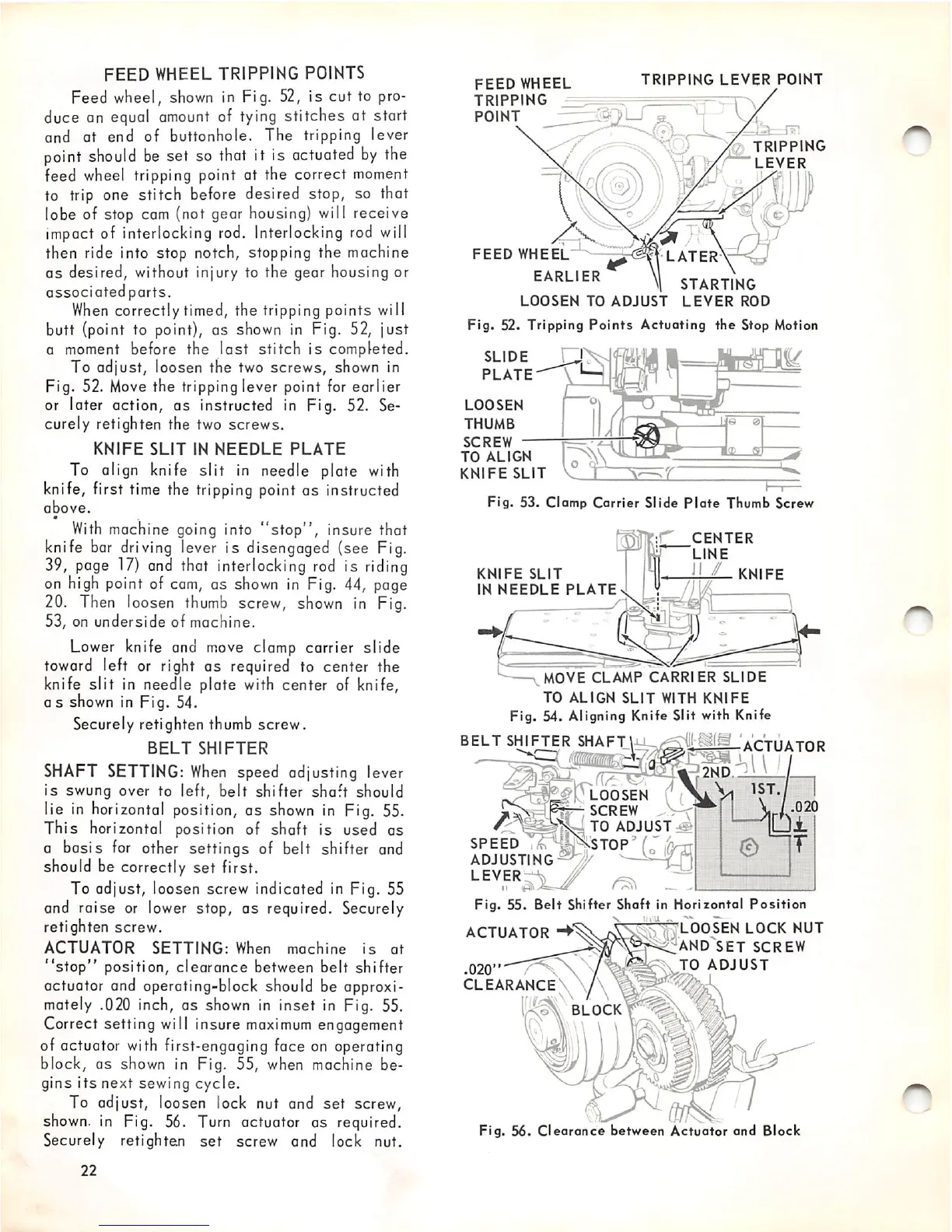

Feed wheel,

shown

in Fig. 52, is cut to pro

duce on

equci

amount

of

tying

stitches at start

and at end of buttonhole. The tripping lever

point

should

be

set so

that

it is

actuated

by

the

feed

wheel

tripping point at the correct

moment

to trip one stitch before desired stop, so that

lobe of stop cam (not gear housing) will receive

impact of interlocking

rod.

Interlocking

rod

will

then ride into stop notch, stopping the machine

as

desired, without injury to the gear housing or

associated parts.

When

correctly timed, the tripping points will

butt (point to point), as shown in Fig. 52, just

a moment before the

last

stitch

is completed.

To adjust, loosen the two

screws,

shown in

Fig. 52.

Move

the tripping lever point for earlier

or later action, as instructed in Fig. 52. Se

curely retighten the two screws.

KNIFE

SLIT

IN

NEEDLE

PLATE

To align knife

slit

in needle plate with

knife, first time the tripping point as instructed

above.

m

With

machine going into

"stop",

insure that

knife

bar

driving

lever is disengaged (see Fig.

39,

page

17)

and

that

interlocking

rod

is

riding

on

high

point of

cam,

as

shown

in Fig. 44, page

20.

Then

loosen

thumb

screw,

shown

in Fig.

53, on

underside

of machine.

Lower

knife and

move

clamp carrier slide

toward left or right as required to center the

knife

slit

in needle plate with center of knife,

Gs

shown

in Fig. 54.

Securely retighten thumb screw.

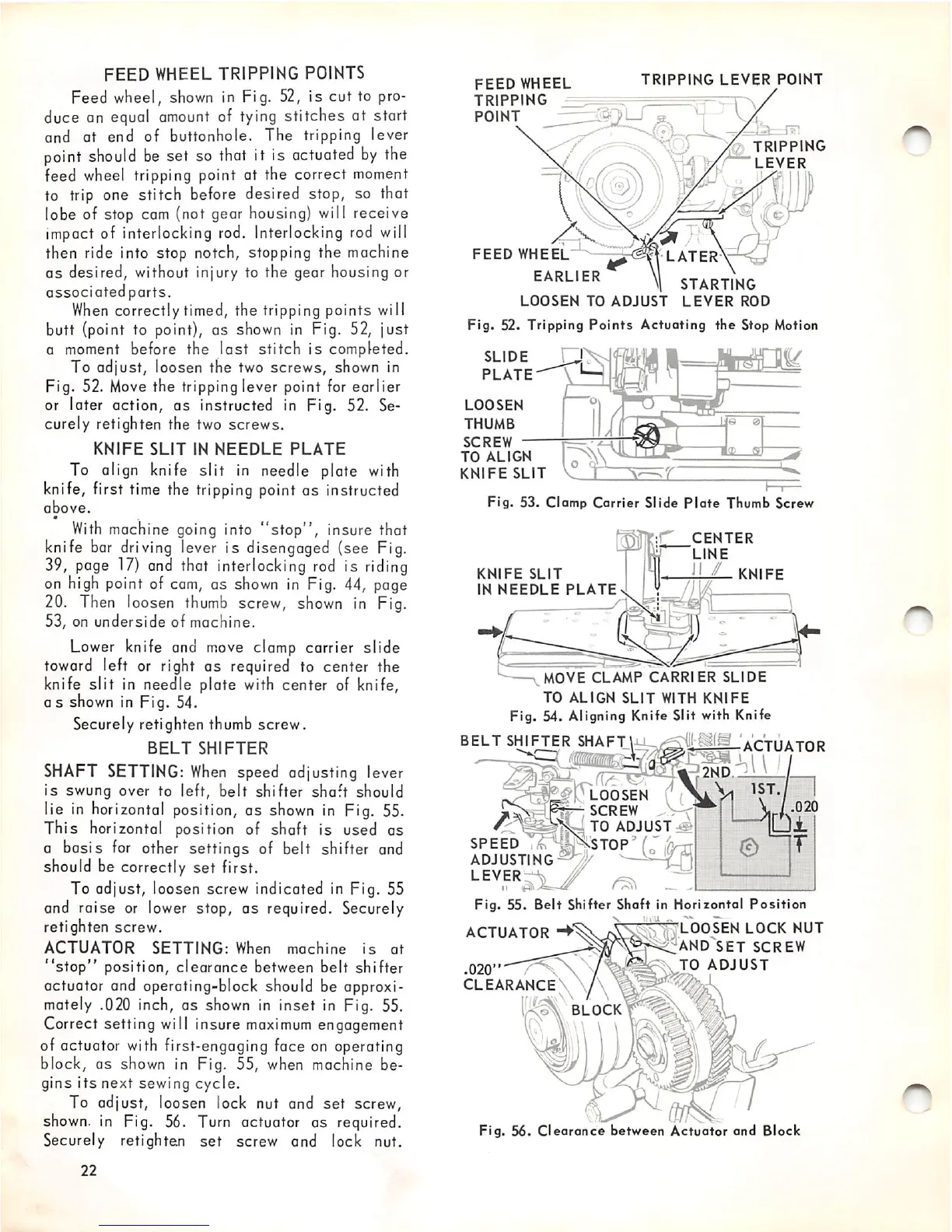

BELT

SHIFTER

SHAFT

SETTING:

When

speed adjusting lever

is

swung over to left,

belt

shifter

shaft

should

lie

in

horizontal position, as

shown

in

Fig. 55.

This horizontal position of shaft is used as

a basis

for

other settings of belt shifter and

should be correctly

set

first.

To adjust, loosen screw indicated in Fig. 55

and raise or lower stop, as required. Securely

retighten screw.

ACTUATOR

SETTING:

When

machine

is

at

"stop"

position,

clearance

between belt shifter

actuator and operating-block should be approxi

mately .020 inch, as

shown

in inset in Fig. 55.

Correct setting will insure

maximum

engagement

of actuator with first-engaging face on operating

block,

OS

shown in Fig. 55,

when

machine be

gins

its

next sewing cycle.

To adjust, loosen lock nut and set screw,

shown,

in Fig. 56. Turn actuator as required.

Securely retighten

set

screw and lock nut.

22

FEED

WHEEL

TRIPPING

POINT

TRIPPING

LEVER

POINT

FEED

WHEEL

EARLIER

LOOSEN

TO

ADJUST

LEVER

ROD

Fig. 52. Tripping

Points

Actuating

the

Stop Motion

SLIDE

PLATE

LOOSEN

THUMB

SCREW

TO

ALIGN

KNIFE

SLIT

Fig.

53.

Clamp

Carrier

Slide

Plate

Thumb

Screw

KNIFE

SLIT

IN

NEEDLE

PLATE

LATER

TRIPPING

LEVER

CENTER

LINE

^

KNIFE

MOVE

CLAMP

CARRIER

SLIDE

TO

ALIGN

SLIT

WITH

KNIFE

Fig. 54. Aligning Knife Slit with Knife

•"

mm

BELT

SHIFTER

SHAFT!

ACTUATOR

ADJUSTING

LEVER

ACTUATOR

.020"

CLEARANCE

2ND.:^

LOOSEN

SCREW

SPEED

Fig.

55.

Beit

Shifter Shaft in Horizontal

Position

LOOSEN

LOCK

NUT

AND^SET

SCREW

TO

ADJUST

•r/.

BLOCK

to'adjust--

Fig.

56.

Clearance

between

Actuator

and

Block

Loading...

Loading...