REAR

EDGE

OF

BLADES

FLUSH

WITH

INSIDE

EDGE

OF

CHECK

LOOSEN

LOCK

NUT'"""^P4

FORWARD

POSITION

CONNECTING

ROD

- ADJUST

STOP

NUT k '

_ AGAINST

\NYLON

WASHER

Fig.

75.

Forward

Position

of

Blades

LATCH

RELEASING

SCREW

LOOSEN

LOCK

NUT

BLADE

IS

FLUSH

WITH

INSIDE

LEFT

EDGE

OF

CHECK

mimnmiimmmmMmiinri

LATCH

Fig.

76.

Cocked

Position

of

Blades

PRESSURE

s.

LOOSEN

LOCK

NUT

TURN

SCREW

TO

ADJUST

PRESSURE

MORE

PRESSURE

Fig. 77. Regulating Pressure on Blodes

UPPER-THREAD

CUTTING

AND

CLAMPING

BLADES

(continued)

REMOVAL:

Remove

connecting rod screw and

check-holder

screw,

shown

in

Fig.

73.

Remove

clamp

check

from

machine

and

turn

it upside

down

as

shown

In

Fig. 74.

Remove

small

screw

at

front

end

of

mat

on

bottom of check and swing mat out of way, as

shown in Fig. 74.

Remove large blade-holder screw. Remove

clamping blade and upper-thread cutting blade.

REPLACEMENT:

Replace

new cutting

blade

and clamping blade fastening them in place with

blade holder screw. Replace mat. Replace clamp

check on holder, fastening it to holder with

large screw and to connecting rod with small

screw, as shown in Fig. 73.

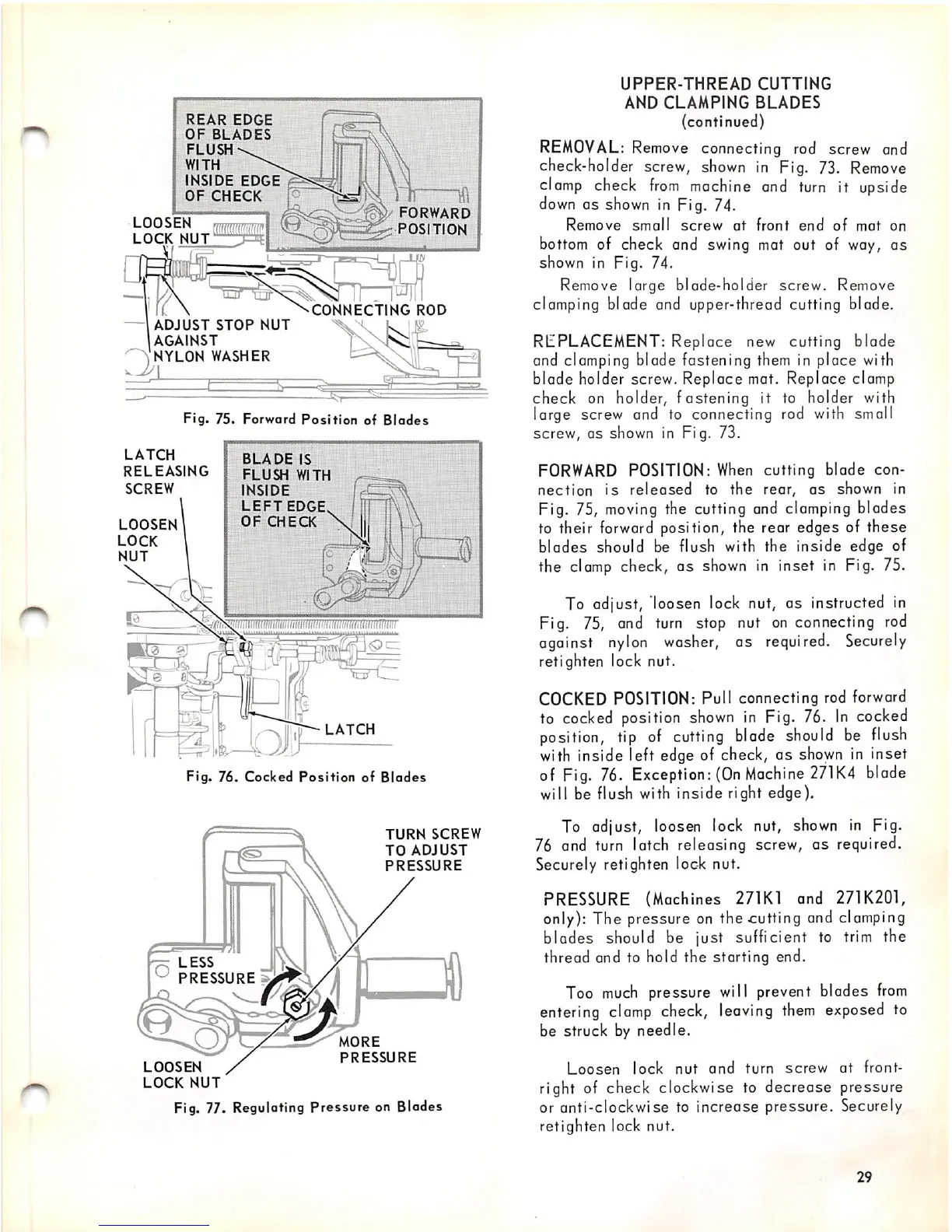

FORWARD

POSITION:

When

cutting blade con

nection

is

released

to

the

rear,

as

shown in

Fig. 75,

moving

the cutting and clamping blades

to their forward position, the rear edges of these

blades

should be flush with the inside edge of

the clamp check,

as

shown in inset in Fig. 75.

To adjust, loosen lock nut, as instructed in

Fig.

75,

and

turn

stop nut

on

connecting

rod

against

nylon

washer,

as

required.

Securely

retighten lock nut.

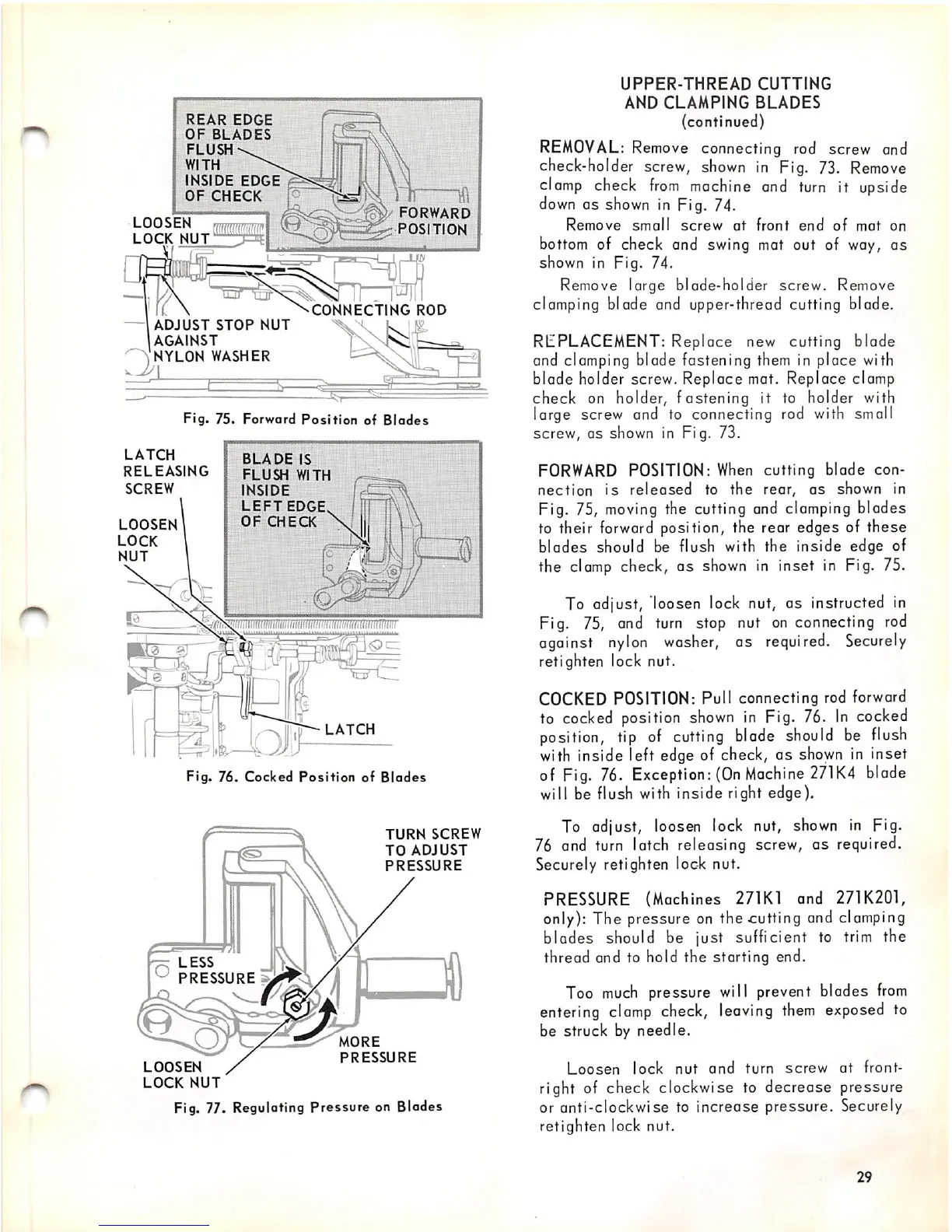

COCKED

POSITION: Pull connecting rod forward

to

cocked

position

shown

in

Fig.

76.

In

cocked

position,

tip

of

cutting

blade

should

be

flush

with inside left edge of check, as

shown

in inset

of

Fig.

76.

Exception:

(On

Machine

271K4

blade

will be flush with inside right edge).

To adjust, loosen lock nut,

shown

in Fig.

76 and

turn

latch releasing screw, as required.

Securely retighten

loc-k

nut.

PRESSURE (Machines 271K1 and 271K201,

only): The pressure on the

Glutting

and clamping

blades should be just sufficient to

trim

the

thread and to hold the starting end.

Too

much

pressure will prevent blades

from

entering

clamp

check,

leaving

them

exposed

to

be struck by needle.

Loosen

lock

nut

and

turn

screw

at

front-

right of check clockwise to decrease pressure

or anti-clockwise to

increase

pressure. Securely

retighten lock nut.

29

Loading...

Loading...