UNDER-THREAD

CUTTING

BLADE

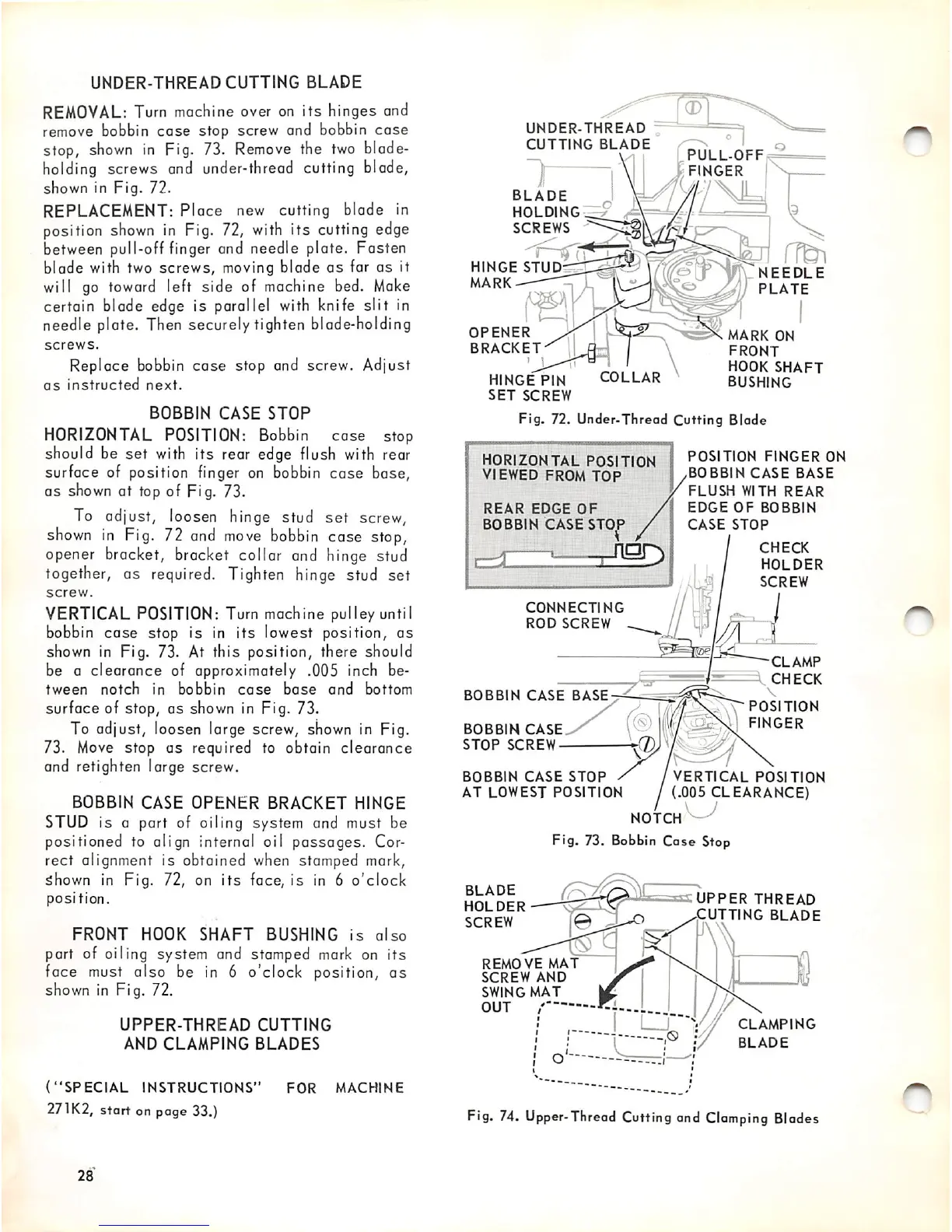

REMOVAL:

Turn machine over

on

its hinges and

remove bobbin case stop screw and bobbin

case

stop,

shown

in

Fig. 73.

Remove

the

two

blade-

holding screws and under-thread cutting blade,

shown in Fig. 72.

REPLACEMENT: Place new cutting blade in

position

shown

in Fig. 72,

with

its cutting edge

between pull-off finger and needle plate. Fasten

blade with two screws, moving blade

as

far as it

will go

toward

left side of machine bed.

Make

certain blade edge is parallel with knife

slit

in

needle plate. Then securely tighten blade-holding

screws.

Replace bobbin

case

stop and screw. Adjust

as

instructed

next.

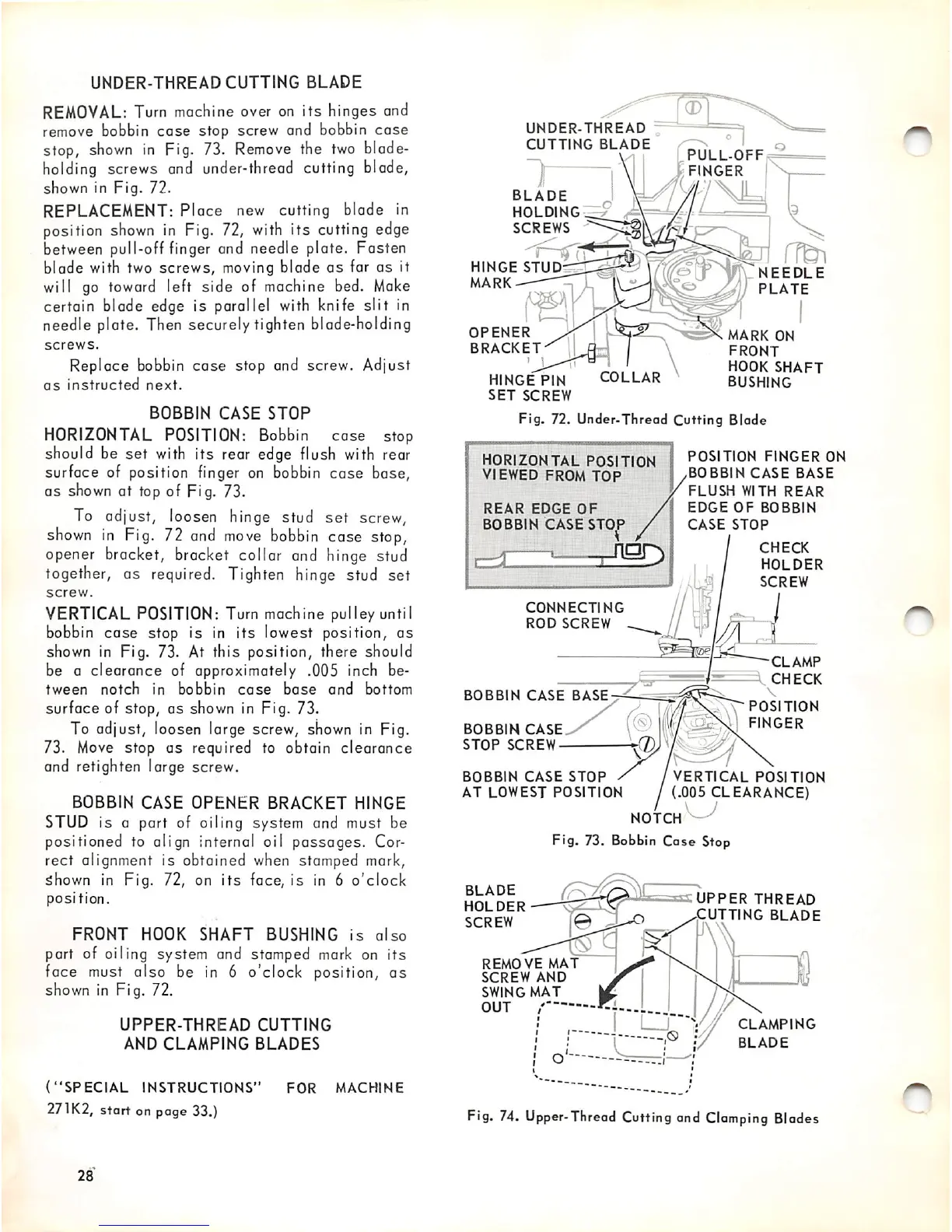

BOBBIN

CASE

STOP

HORIZONTAL POSITION: Bobbin cose stop

should be

set

with its rear edge flush with rear

surface of position finger on bobbin

case

base,

as

shown

at top of Fig. 73.

To adjust, loosen hinge stud

set

screw,

shown

in

Fig. 72

and

move

bobbin

case stop,

opener bracket, bracket collar and hinge stud

together, as required. Tighten hinge stud set

screw.

VERTICAL POSITION: Turn machine pulley until

bobbin case stop is in its lowest position, as

shown in Fig. 73. At this position, there should

be a

clearance

of approximately .005 inch be

tween

notch

in

bobbin

cose

base

and

bottom

surface of stop, as shown in Fig. 73.

To adjust, loosen large screw, shown in Fig.

73.

Move

stop as required to obtain

clearance

and retighten large screw.

BOBBIN

CASE

OPENER

BRACKET

HINGE

STUD is a part of oiling system and must be

positioned to align internal oil passages. Cor

rect alignment is obtained when stamped mark,

5hown in Fig. 72, on

its

face, is in 6

o'clock

position.

FRONT

HOOK

SHAFT

BUSHING

is

also

port of oiling system and stamped mark on

its

face must also be in 6 o'clock position,

as

shown in Fig. 72.

UPPER-THREAD

CUTTING

AND

CLAMPING

BLADES

("SPECIAL

INSTRUCTIONS"

FOR

MACHINE

271K2,

start on page 33.)

28

UNDER-THREAD

CUTTING

BLADE

BLADE

HOLDING

SCREWS

HINGE

STUD

MARK

OPENER

BRACKET

HINGE

PIN

SET

SCREW

COLLAR

Ftg.

72. Under-Thread

Cutting

Blade

HORIZONTAL POSITION

VIEWED FROM

TOP

REAR

EDGE

OF

BOBBIN

CASE

STOP

'

riTSQ

CONNECTING

ROD

SCREW

BOBBIN

CASE

BASE-^-^

-__

BOBBIN

CASE

STOP

SCREW

BOBBIN

CASE

STOP

AT

LOWEST

POSITION

PULL-OFF

FINGER

r?^

NEEDLE

PLATE

mark

ON

FRONT

HOOK

SHAFT

BUSHING

POSITION

FINGER

ON

,BOBBIN

CASE

BASE

FLUSH

WITH

REAR

EDGE

OF

BOBBIN

CASE

STOP

CHECK

HOLDER

SCREW

CLAMP

CHECK

V

POSITION

FINGER

VERTICAL

POSITION

:.005 CLEARANCE)

NOTCH

Fig. 73. Bobbin Case Stop

BLADE

HOLDER

SCREW

[0

rf

REMOVE

MAT

SCREW

AND

SWING

MAT

OUT

UPPER

THREAD

UTTING

BLADE

CLAMPING

BLADE

Fig. 74.

Upper-Thread

Cuttingand

Clamping

Blades

Loading...

Loading...