2.

LOOSEN

THIS

SCREW

1.

LOOSEN

7- ) K u

AND

RAISE

OR

LOWER

^BRACKET TO

OBTAIN

J-

- i

AND

MOVE

PLATE

TO

OBTAIN

1/16"

CLEARANCE

TH

S

SCREU

1/16"

CLEARANCE

ROLLER

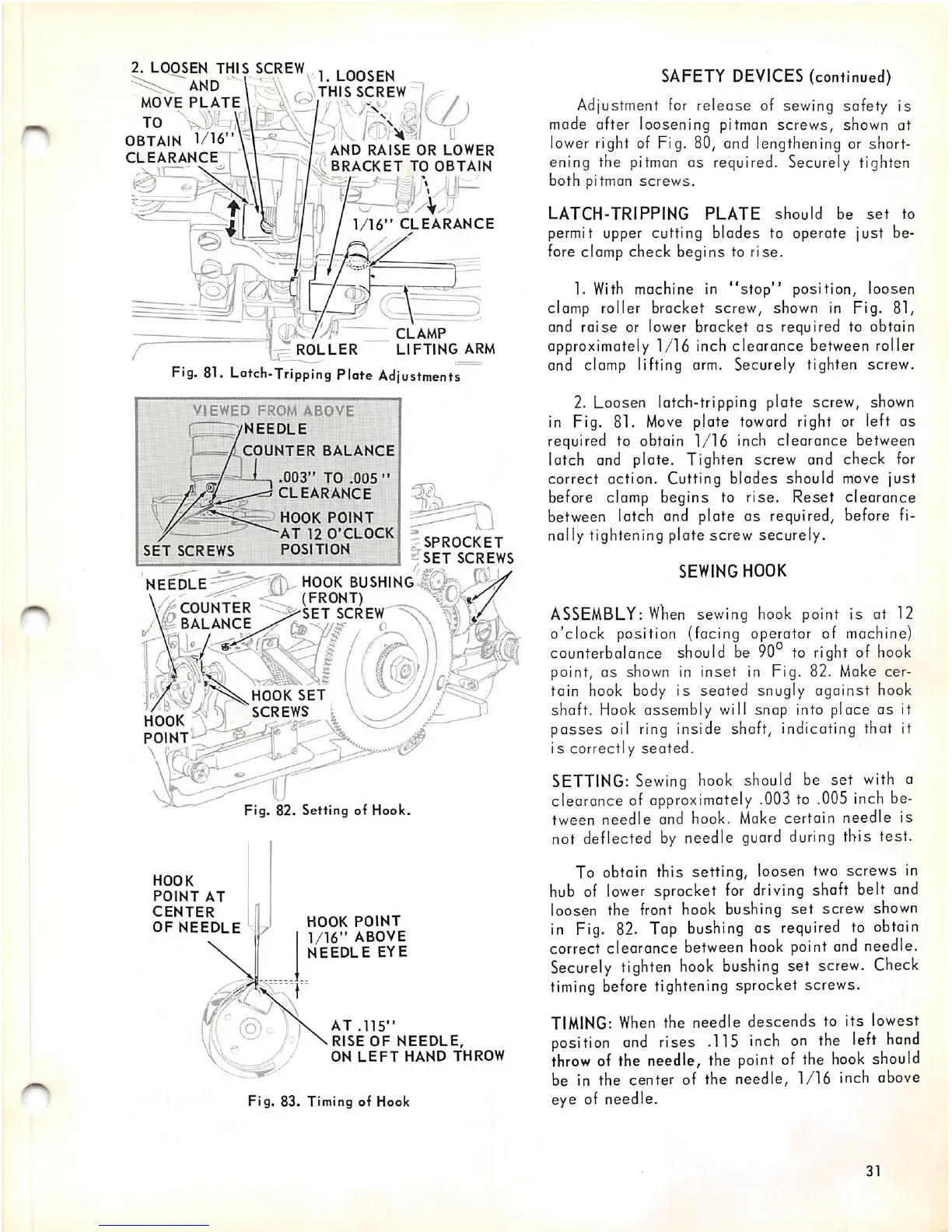

Fig. 81. Lotch-Tripping Plate Adjustments

CLAMP

LIFTING

ARM

VIEWED

FROM

ABOVE

NEEDLE

COUNTER

BALANCE

SET

SCREWS

NEEDLE

COUNTER

BALANCE

HOOK

POINT

,

.003"

TO

.005"

CLEARANCE

HOOK

POINT

AT

12

O'CLOCK

POSITION

(FRONT)

SET

SCREW

i

HOOK

SET

SCREWS

'V

r?\',

.1

SPROCKET

SET

SCREWS

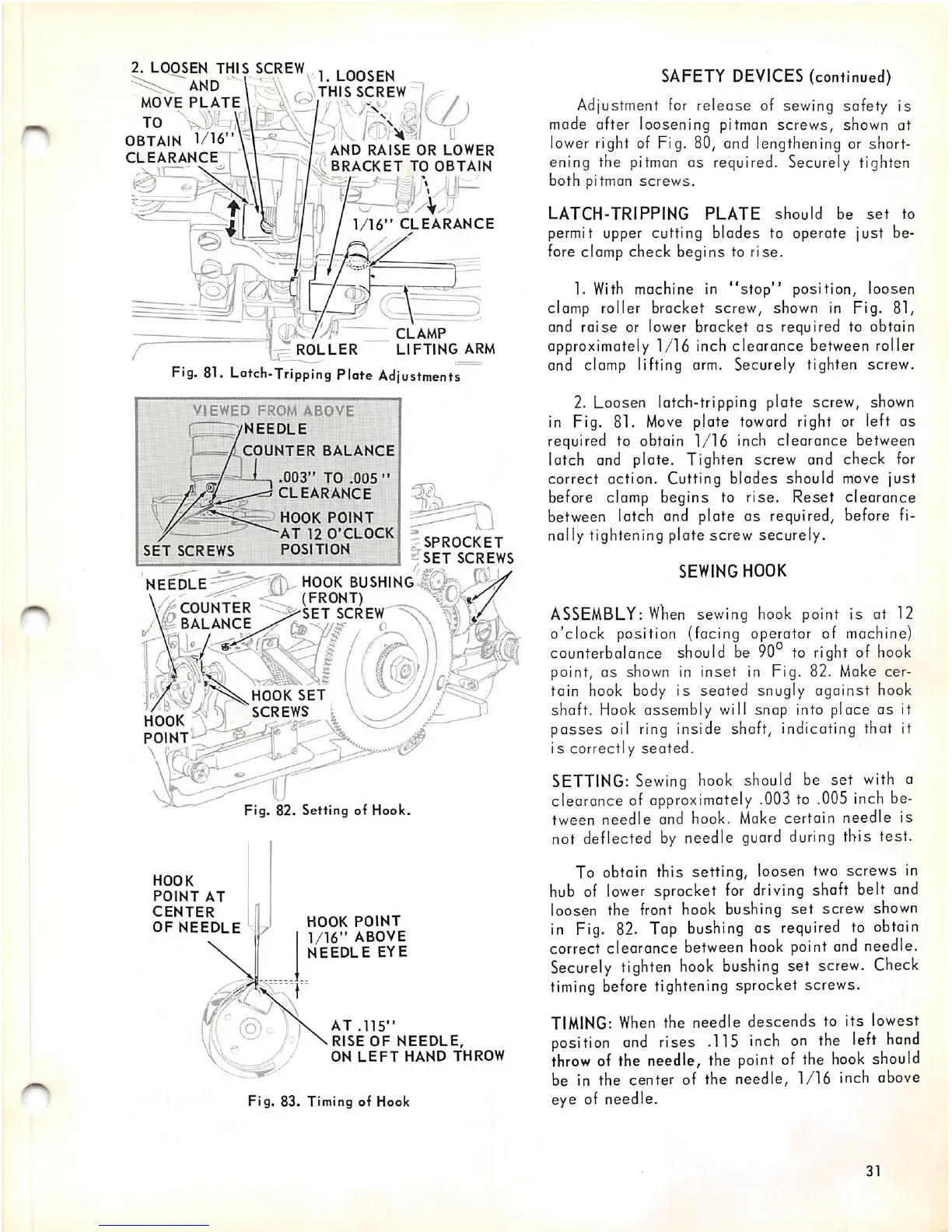

Fig.

82.

Setting

of Hook.

HOOK

POINT

AT

CENTER

OF

NEEDLE

HOOK

POINT

1/16"

ABOVE

NEEDLE

EYE

AT

.115"

RISE

OF

NEEDLE,

ON

LEFT

HAND

THROW

Fig.

83. Timing of Hook

SAFETY DEVICES (continued)

Adjustment for

release

of sewing safety is

made after loosening pitman

screws,

shown at

lower right of Fig. 80, and lengthening or short

ening the pitman as required. Securely tighten

both pitman

screws.

LATCH-TRIPPING

PLATE

should

be

set

to

permit upper cutting blades to operate just be

fore clamp check begins to rise.

1.

With

machine in

"stop"

position, loosen

clamp roller bracket screw, shown in Fig. 81,

and

raise

or lower bracket

as

required to obtain

approximately 1/16 inch clearance between roller

and clamp lifting arm. Securely tighten screw.

2. Loosen latch-tripping plate screw, shown

in Fig. 81.

Move

plate

toward

right or left as

required to obtain 1/16 inch clearance between

latch and plate. Tighten screw and check for

correct action. Cutting blades should

move

just

before clamp begins to rise. Reset clearance

between latch and plate as required, before fi

nally tightening plate screw securely.

SEWING HOOK

ASSEMBLY:

WVien

sewing

hook

point

is at 12

o'clock position (facing operator of machine)

counterbalance

should

be

90°

to

right

of

hook

point, as shown in inset in Fig. 82.

Make

cer

tain hook body is seated snugly against hook

shaft. Hook assembly will snap into place

as

it

passes

oil ring inside shaft, indicating that it

is

correctly

seated.

SETTING:

Sewing

hook

should

be set

with

a

clearance of

approximately

.003

to

.005

inch

be

tween

needle

and hook. Make

certain

needle

is

not deflected

by

needle

guard

during

this test.

To obtain this setting, loosen two screws in

hub

of

lower

sprocket

for

driving

shaft belt

and

loosen the front hook bushing

set

screw shown

in Fig. 82. Tap

bushing

as

required

to obtain

correct clearance between hook point

and

needle.

Securely

tighten

hook

bushing

set

screw.

Check

timing before tightening sprocket screws.

TIMING:

When

the needle

descends

to

its

lowest

position

and

rises

.115

inch

on

the

left

hand

throw

of the needle, the point of the

hook

should

be in the center of the needle, 1/16 inch above

eye of needle.

31

Loading...

Loading...