NUMBER OF STITCHES

IN

BUTTONHOLE

{See Fig. 26)

The

number

of

stitches

in a

buttonhole

is

controlled by the

set

of stitch regulating gears

selected

for

use.

IMPORTANT: To avoid disturbingthe timing

of the machine, do not permit any of the gear

shafts

to turn, while changing stitch regulating

gears.

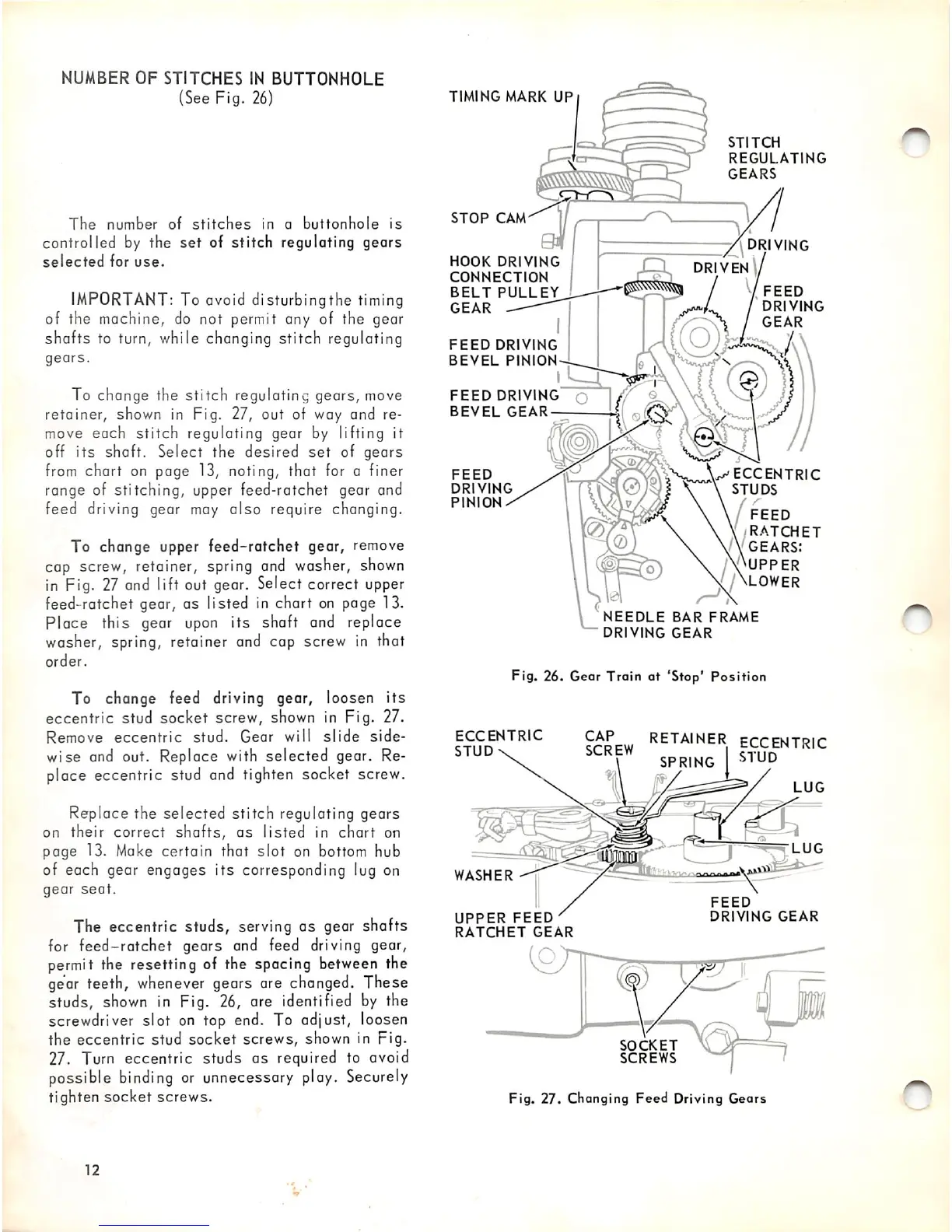

To change the

stitch

regulating gears, move

retainer, shown in Fig. 27, out of way and re

move each

stitch

regulating gear by lifting it

off

its

shaft. Select the desired

set

of gears

from

chart on page 13, noting, that for a finer

range of stitching, upper feed-ratchet gear and

feed driving gear may also require changing.

To change upper feed-ratchet gear, remove

cap screw, retainer, spring

and

washer,

shown

in Fig.

27

and

lift out gear. Select correct

upper

feed-ratchet gear, as listed in chart on page 13.

Place this gear

upon

its shaft and replace

washer, spring, retainer and cap screw

in

that

order.

To change feed driving gear, loosen

its

eccentric

stud

socket

screw, shown in Fig. 27.

Remove

eccentric

stud.

Gear will

slide

side-

wise and out. Replace with selected gear. Re

place eccentric stud and tighten socket screw.

Replace the selected stitch regulating gears

on their

correct

shafts,

as

listed

in

chart

on

page 13.

Make

certain that slot on bottom hub

of each gear engages

its

corresponding lug on

gear

seat.

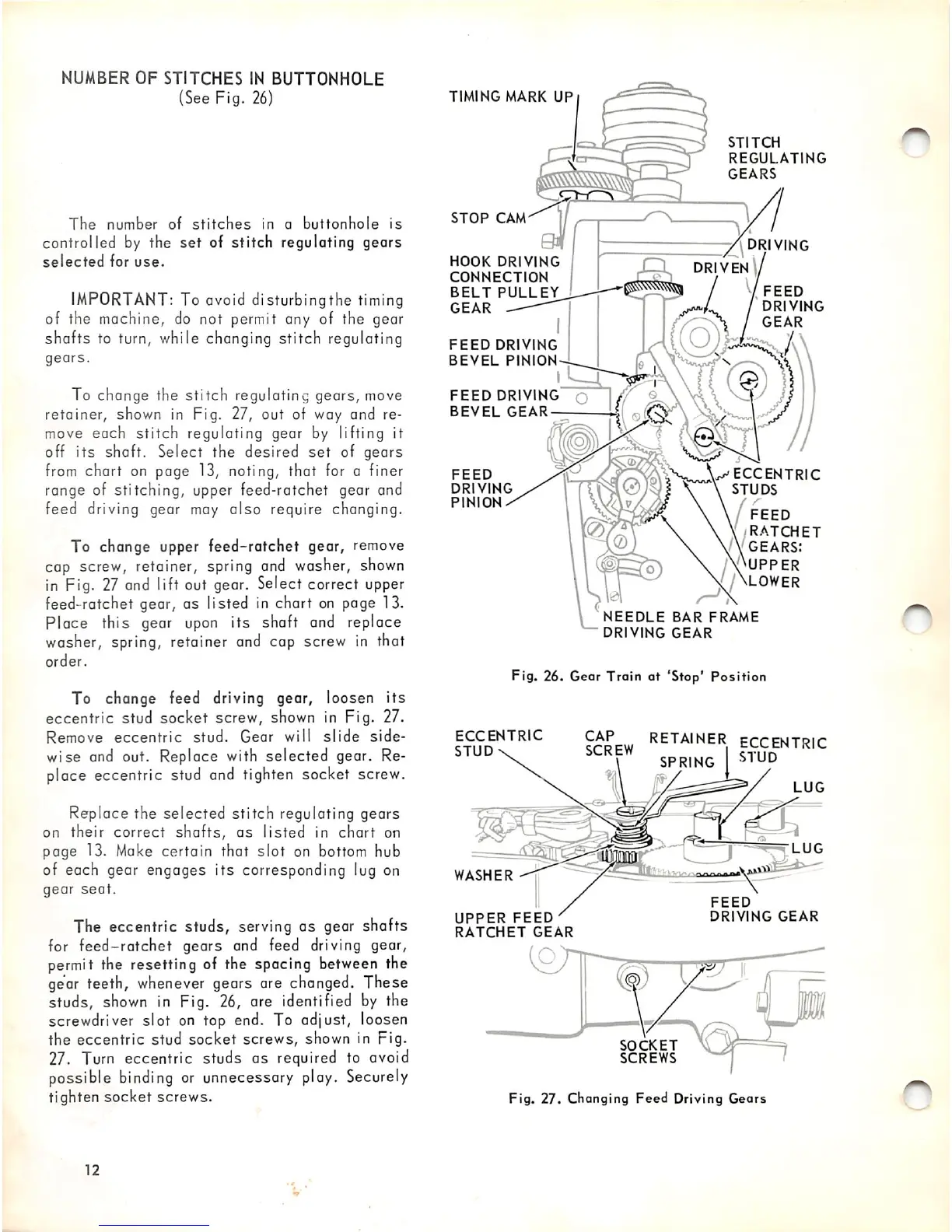

The eccentric studs, serving as gear shafts

for

feed-ratchet

gears and feed driving gear,

permit

the resetting of the spacing

between

the

gear teeth,

whenever

gears are changed. These

studs, shown in Fig. 26, ore identified

by

the

screwdriver slot on top end. To adjust, loosen

the

eccentric

stud

socket

screws,

shown in

Fig.

27. Turn eccentric studs as required to avoid

possible

binding

or

unnecessary

play.

Securely

tighten socket screws.

12

TIMING

MARK

UP

STOP

CAM

HOOK

DRIVING

CONNECTION

BELT

PULLEYJ

GEAR

FEED

DRIVING

BEVEL

PINION

FEED

DRIVING q

BEVEL

GEAR

FEED

DRIVING

PINION

STITCH

REGULATING

GEARS

\

DRIVING

driven!

/

FEED

DRIVING

GEAR

eccentric

STUDS

FEED

ratchet

gears;

UPPER

lower

NEEDLE

BAR

FRAME

DRIVING

GEAR

Fig. 26. Gear Train at 'Stop' Position

ECCENTRIC

STUD

WASHER

UPPER

FEED

RATCHET

GEAR

SCREW

ECCENTRIC

SPRING

STUD

SOCKET

SCREWS

LUG

FEED

DRIVING

GEAR

Fig.

27.

Changing

Feed

Driving

Gears

Loading...

Loading...