STOP

MOTION

(continued)

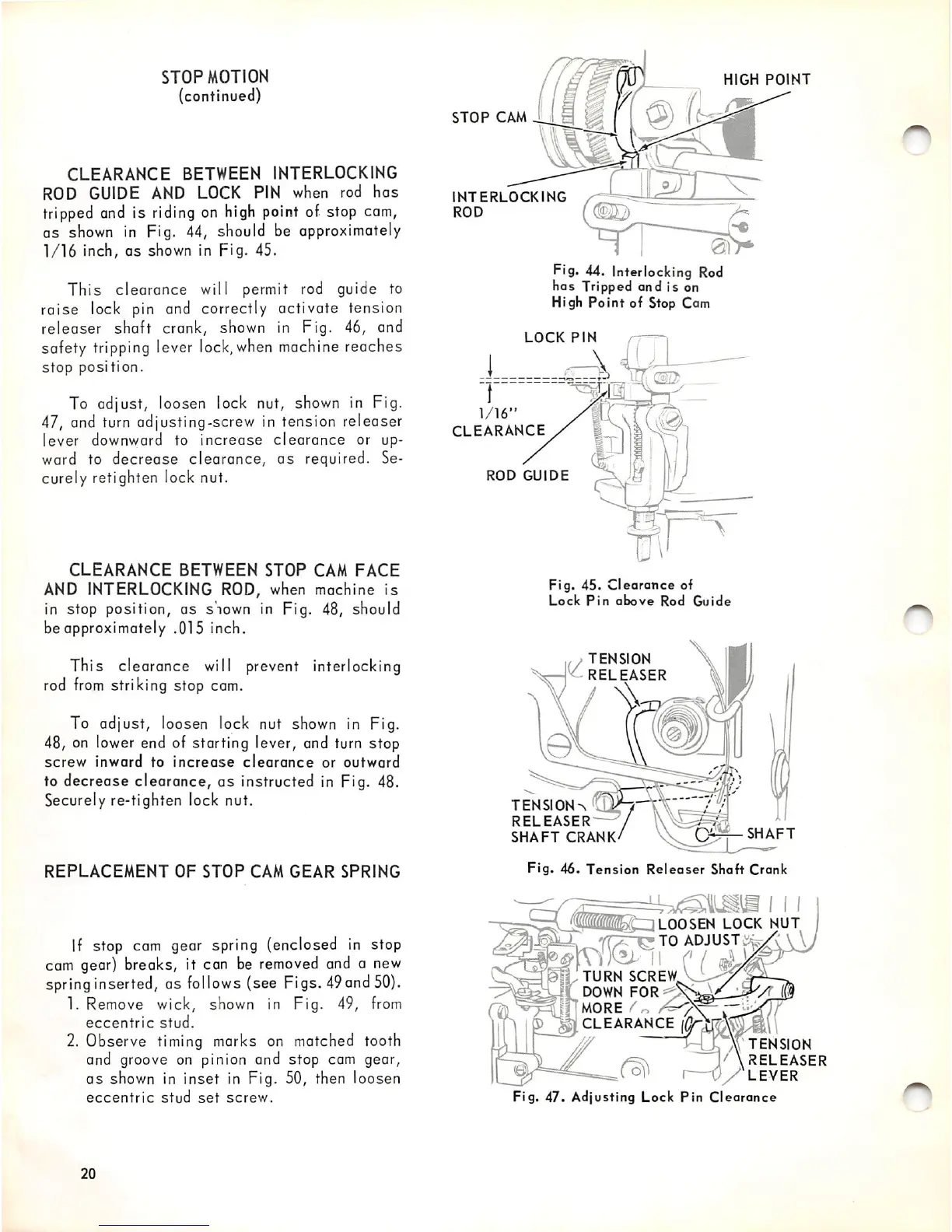

CLEARANCE

BETWEEN INTERLOCKING

ROD GUIDE AND LOCK PIN when rod

has

tripped

and

is

riding

on

high

point

of stop

cam,

as

shown

in Fig. 44, should be approximately

1/16

inch, as shown in Fig. 45.

This clearance will permit rod guide to

raise lock pin and correctly activate tension

releaser shaft crank, shown in Fig. 46, and

safety

tripping

lever

lock,

when

machine

reaches

stop

position.

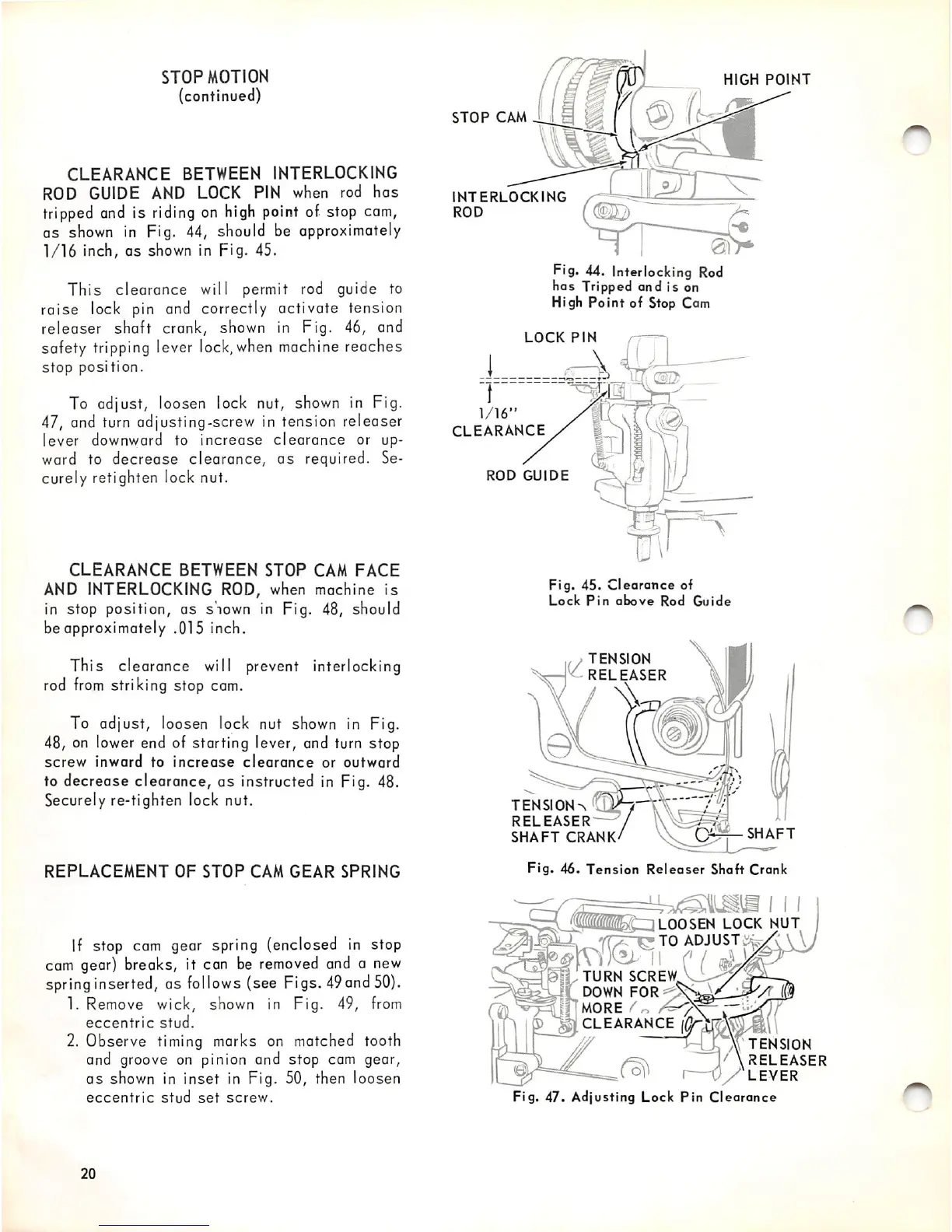

To adjust, loosen lock nut, shown in Fig.

47, and turn adjusting-screw in tension releaser

lever downward to increase

clearance

or up

ward to

decrease

clearance,

as

required. Se

curely retighten lock nut.

CLEARANCE

BETWEEN

STOP

CAM

FACE

AND

INTERLOCKING ROD, when machine

is

in stop position, as shown in Fig. 48, should

be approximately .015 inch.

This clearance will prevent interlocking

rod

from

striking stop cam.

To adjust, loosen lock nut

shown

in Fig.

48, on lower end of starting lever, and turn stop

screw

inward

to

increase

clearance

or

outward

to decrease clearance,

as

instructed in Fig. 48.

Securely re-tighten lock nut.

REPLACEMENT

OF

STOP

CAM

GEAR

SPRING

If stop cam gear spring (enclosed in stop

cam gear) breaks, it can be

removed

and a

new

spring

inserted, as

follows

(see Figs.

49

and

50).

1. Remove wick, shown in Fig. 49,

from

eccentric

stud.

2. Observe timing marks on matched tooth

and groove on pinion and stop

com

gear,

as

shown in inset in Fig. 50, then loosen

eccentric

stud

set

screw.

20

STOP

CAM

INTERLOCKING

ROD

HIGH

POINT

Fig. 44. Interlocking

Rod

has Tripped and is on

High

Point

of Stop Cam

LOCK

PIN

llf;®

a

CLEARANCE

ROD

GUIDE

Fig.

45.

Clearance

of

Lock

Pin

above

Rod

Guide

,,

TENSION

^RELEASER

TENSION

RELEASER

SHAFT

CRANK

Fig.

46.

Tension

Releaser

Shaft

Crank

SHAFT

QLOOSEN

LOCK

NUT

TO

ADJUST,

II f

TURN

SCREW,

DOWN

F0R'/,\2p^

MORE

CLEARANCE

"

Fig.

47.

Adjusting

Lock

Pin

Clearance

TENSION

'

\releaser

LEVER

Loading...

Loading...