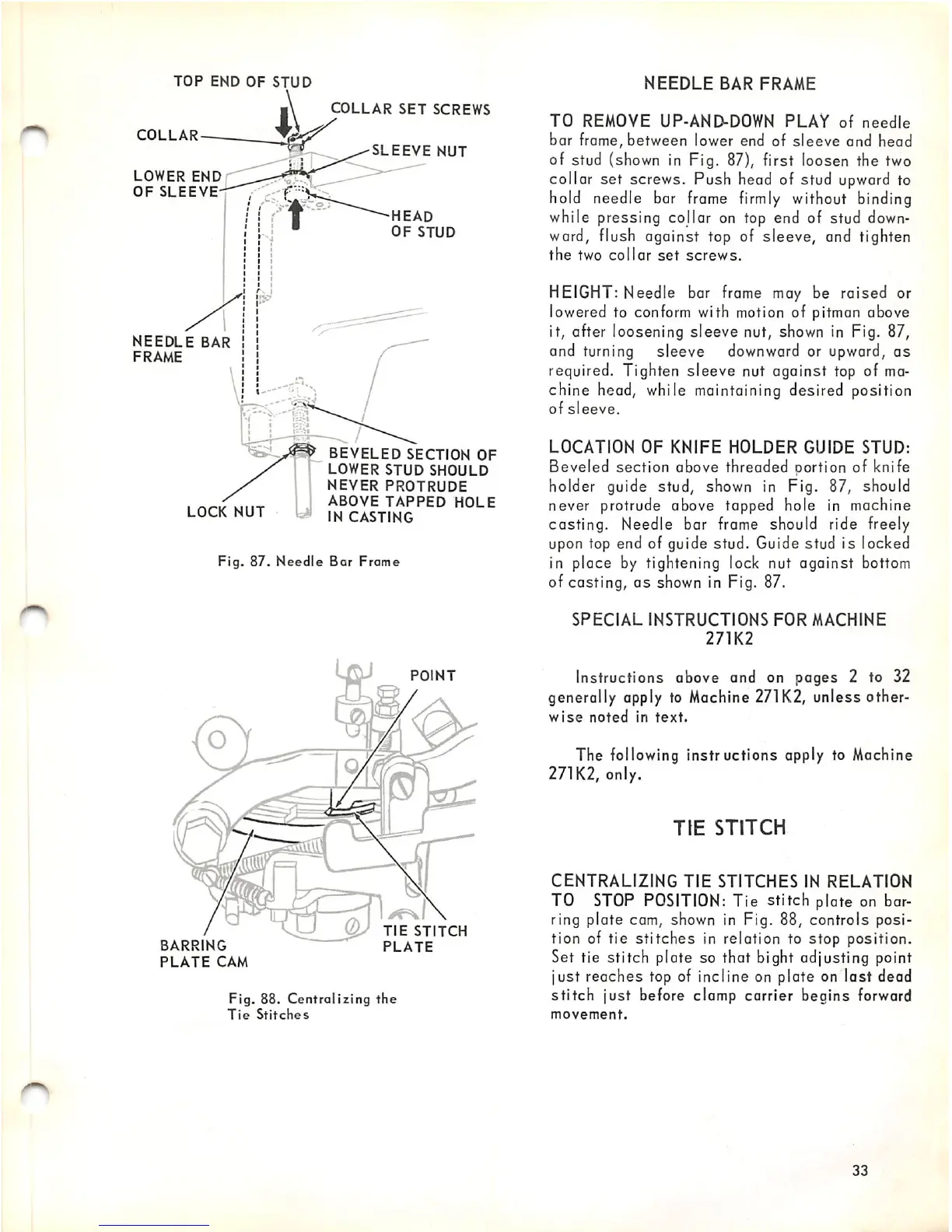

TOP

END

OF

STUD

COLLAR

LOWER

END

OF

SLEEVE

NEEDLE

BAR

FRAME

LOCK

NUT

COLLAR

SET

SCREWS

SLEEVE

NUT

HEAD

OF

STUD

BEVELED

SECTION OF

LOWER

STUD

SHOULD

NEVER

PROTRUDE

ABOVE

TAPPED

HOLE

IN

CASTING

Fig.

87.

Needle

Bar Frame

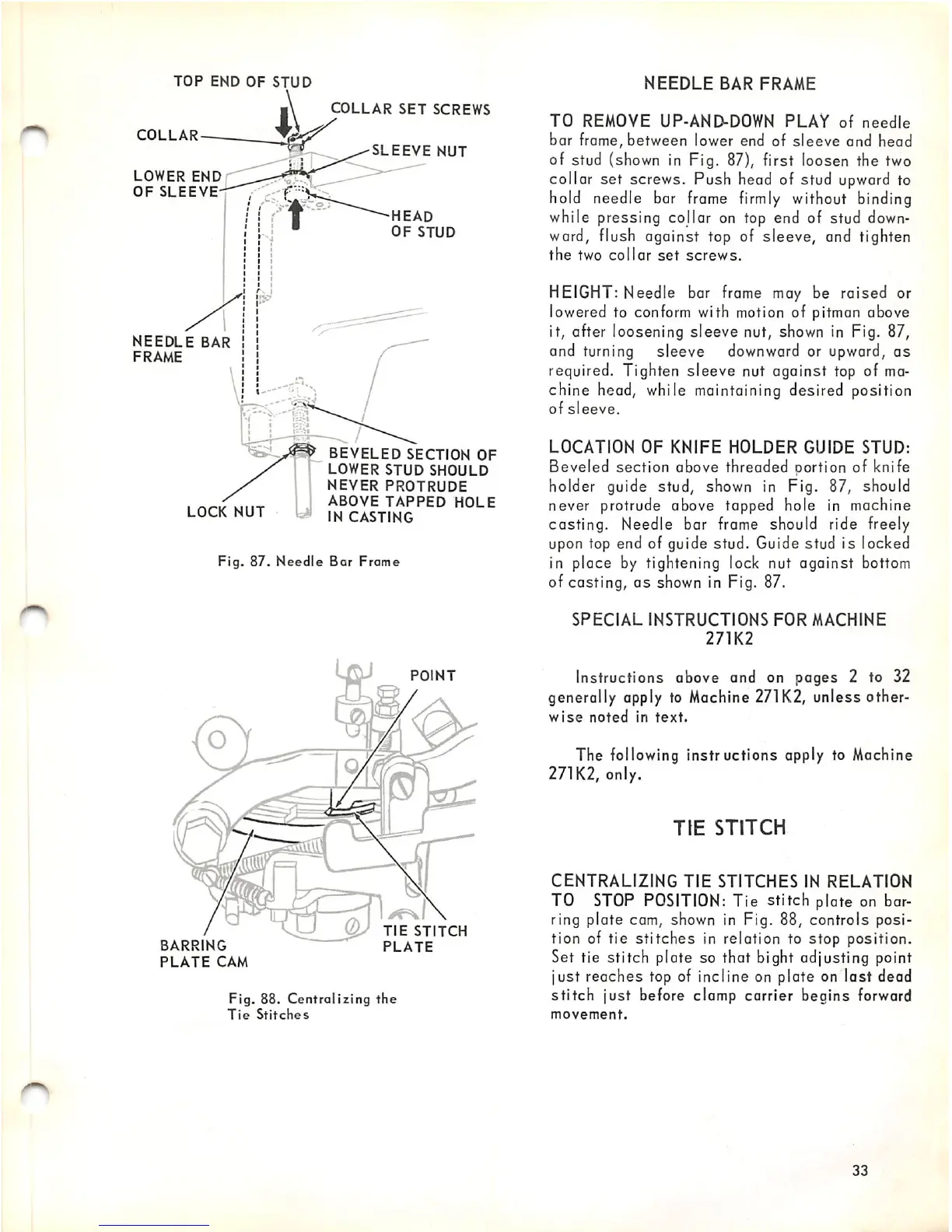

BARRING

PLATE

CAM

o

POINT

TIE

STITCH

PLATE

Fig.

88.

Centralizing

the

Tie

Stitches

NEEDLE

BAR

FRAME

TO

REMOVE UP-AND-DOWN

PLAY

of

needle

bar frame, between lower end of

sleeve

and head

of stud (shown in Fig. 87), first loosen the two

collar

set

screws. Push head of stud

upward

to

hold needle bar

frame

firmly

without binding

while pressing collar on top end of stud

down

ward, flush against top of sleeve, and tighten

the

two

collar

set

screws.

HEIGHT: Needle bar frame may be raised or

lowered to conform with motion of pitman above

it, after loosening

sleeve

nut, shown in Fig. 87,

and turning sleeve

downward

or upward, as

required. Tighten sleeve nut against top of ma

chine head, while maintaining desired position

of

sleeve.

LOCATION

OF

KNIFE

HOLDER

GUIDE

STUD:

Beveled section above threaded portion of knife

holder guide stud, shown in Fig. 87, should

never protrude above tapped hole in machine

casting.

Needle bar frame should ride freely

upon top end of guide stud. Guide stud

is

locked

in place by tightening lock nut against bottom

of casting, as shown in Fig. 87.

SPECIAL

INSTRUCTIONS

FOR

MACHINE

271K2

Instructions above and on pages 2 to 32

generally apply to Machine

271K2,

unless other

wise

noted

in

text.

The following instructions apply to Machine

271K2, only.

TIE

STITCH

CENTRALIZING

TIE

STITCHES

IN

RELATION

TO

STOP

POSITION:

Tie stitch plate on bar

ring plate cam, shown in Fig. 88, controls posi

tion of tie

stitches

in relation to

stop

position.

Set tie stitch plate so that bight adjusting point

just reaches top of incline on plate on lost dead

stitch

just before clamp carrier begins forward

movement.

33

Loading...

Loading...