SPECIAL

INSTRUCTIONS

FOR

MACHINE

271K2

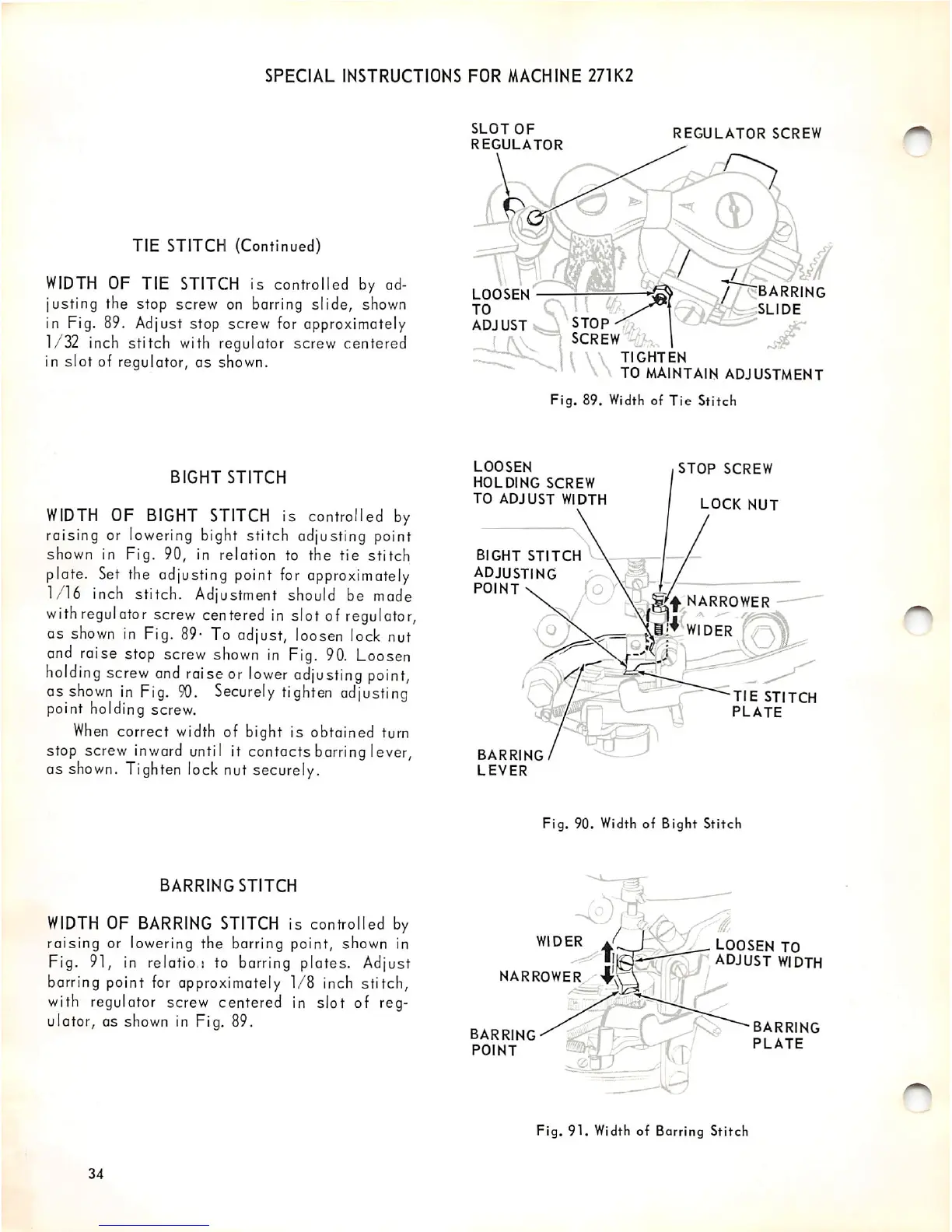

TIE STITCH (Continued)

WIDTH

OF TIE

STITCH

is controlled by ad

justing the stop screw on barring slide, shown

in Fig. 89. Adjust stop screw for approximately

1/32 inch stitch

with

regulator screw centered

in

slot

of regulator, as shown.

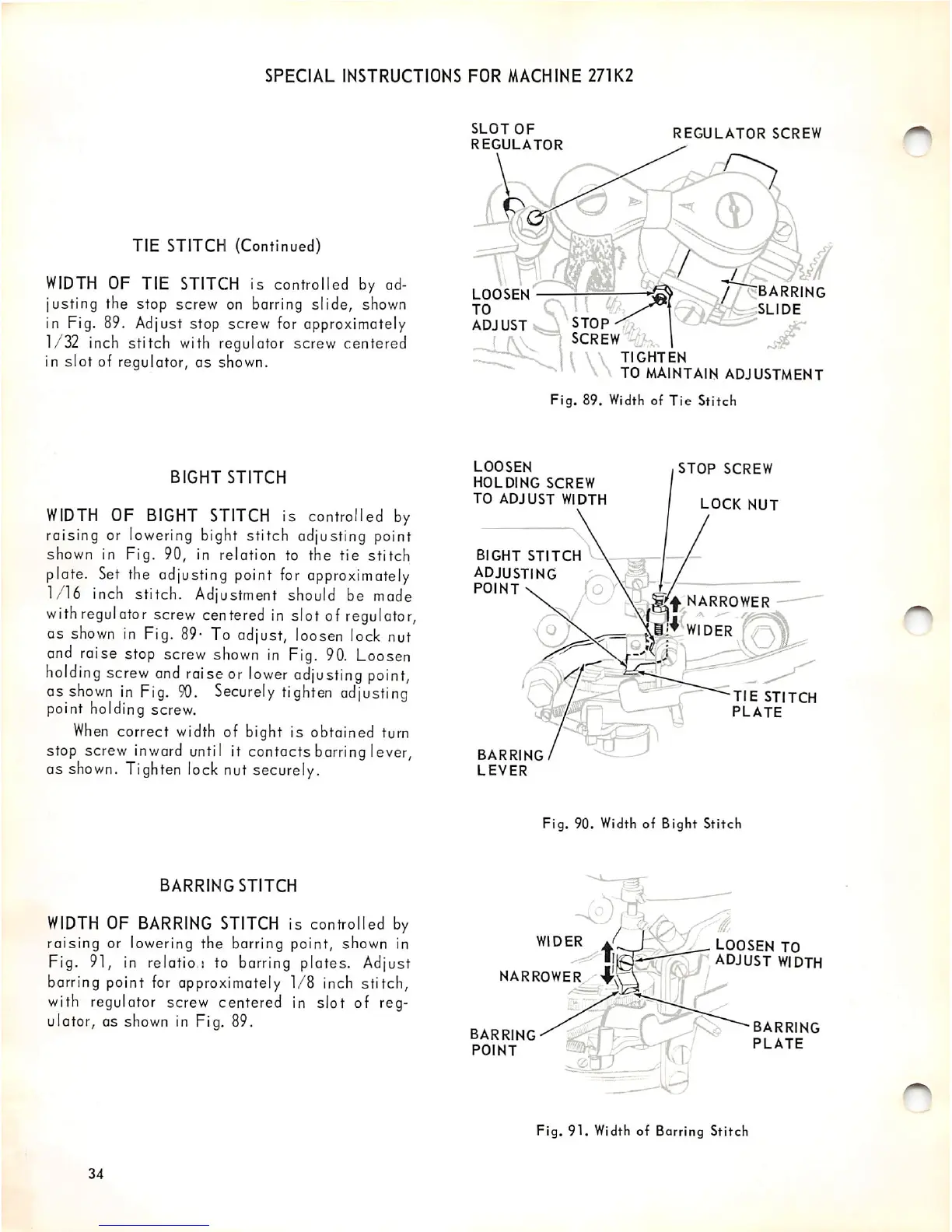

BIGHT

STITCH

WIDTH

OF

BIGHT

STITCH

is controlled by

raising or lowering bight stitch adjusting point

shown

in

Fig.

90, in relation to the

tie

stitch

plate.

Set

the adjusting

point

for

approximately

1/16 inch stitch. Adjustment should be made

with

regul

ator

screw

centered

in

slot of regulator,

as

shown

in

Fig.

89-

To adjust, loosen lock nut

and

raise

stop

screw

shown

in

Fig.

90.

Loosen

holding

screw

and

raise or

lower

adjusting

point,

as

shown

in

Fig.

90.

Securely

tighten

adjusting

point holding screw.

When

correct

width

of bight is obtained turn

stop screw inward until it contacts barring lever,

as

shown.

Tighten

lock nut securely.

BARRING

STITCH

WIDTH

OF

BARRING

STITCH is controlled

by

raising

or lowering the barring point, shown in

Fig. 91, in relatio.j to barring plates. Adjust

barring point

for

approximately 1/8 inch stitch,

with regulator screw centered in slot of reg

ulator, as shown in Fig. 89.

34

SLOT

OF

REGULATOR

ADJUST STOP

SCREW

\

TIGHTEN

REGULATOR

SCREW

y/7

^barring

SLIDE

TO MAINTAIN

ADJUSTMENT

Fig.

89. Width of

Tie

Stitch

LOOSEN

HOLDING

SCREW

TO

ADJUST

WIDTH

BIGHT

STITCH

^

adjusting

POINT

BARRING

LEVER

STOP

SCREW

LOCK

NUT

f

NARROWER

4

TIE

STITCH

PLATE

Fig.

90. Width of

Bight

Stitch

WIDER

NARROWER

V

BARRING

POINT

loosen

to

ADJUST

WIDTH

BARRING

PLATE

Fig.

91. Width of Barring

Stitch

r^

Loading...

Loading...