r\

BELT

Use Machine Driving Belt

(endless)

2T\19I,

furnished

with

machine.

Overtightening of belt

may

cause binding of

machine, due to the extended length of arm shaft

beyond

casting at pulley end. Adjust height of

driving

motor

to tighten belt only sufficiently

to obtain recommended machine driving speed.

DO

NOT

USE

A

LEATHER

BELT.

A

leather

belt can

become

too tight, damaging

arm

shaft;

or too loose, causing non-uniform rotation.

Metal

clipon leather belt

may

set up a vibration

that

interferes

with

belt

shifter.

PRIME

PRIME

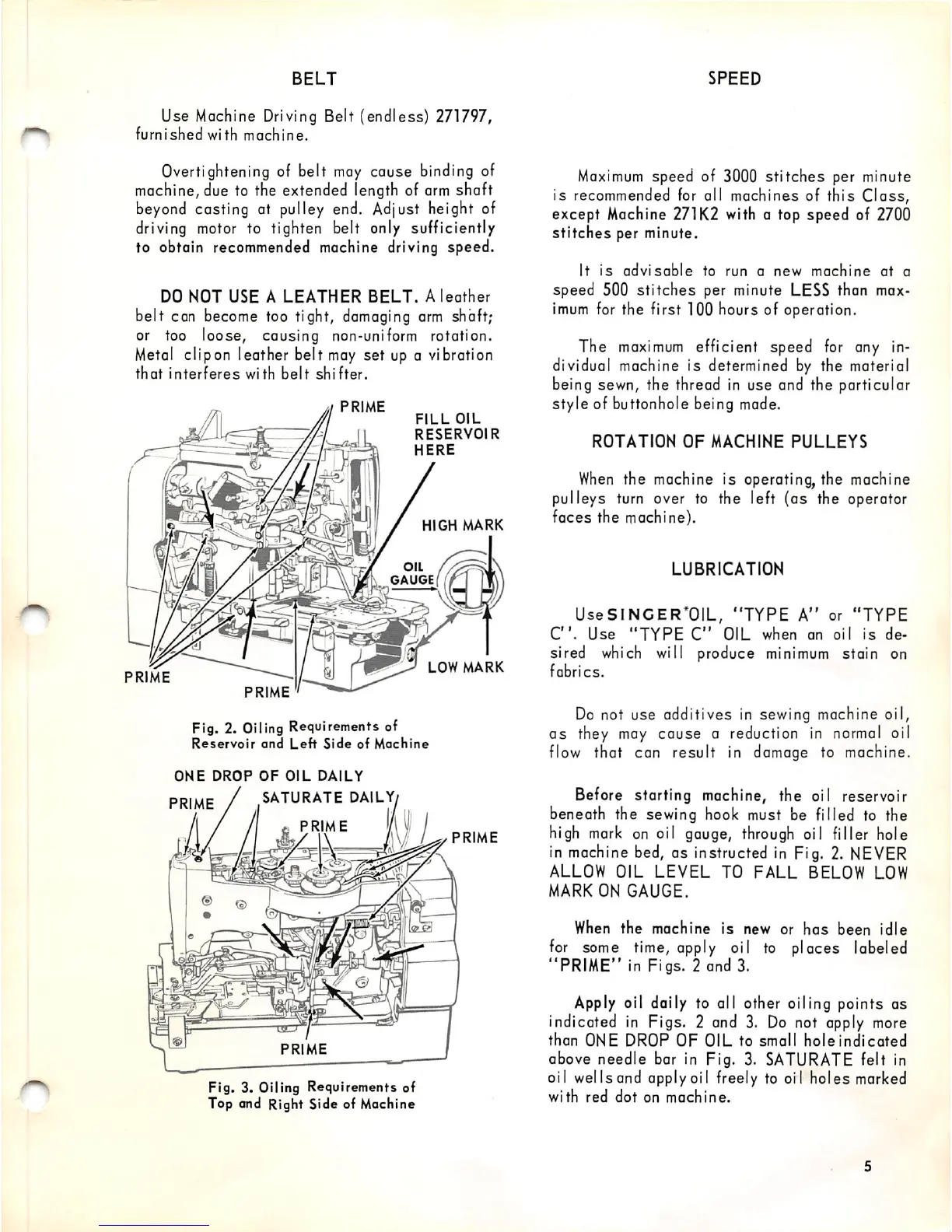

Fig. 2. Oiling Requirements of

Reservoir

and

Left

Side

of

Machine

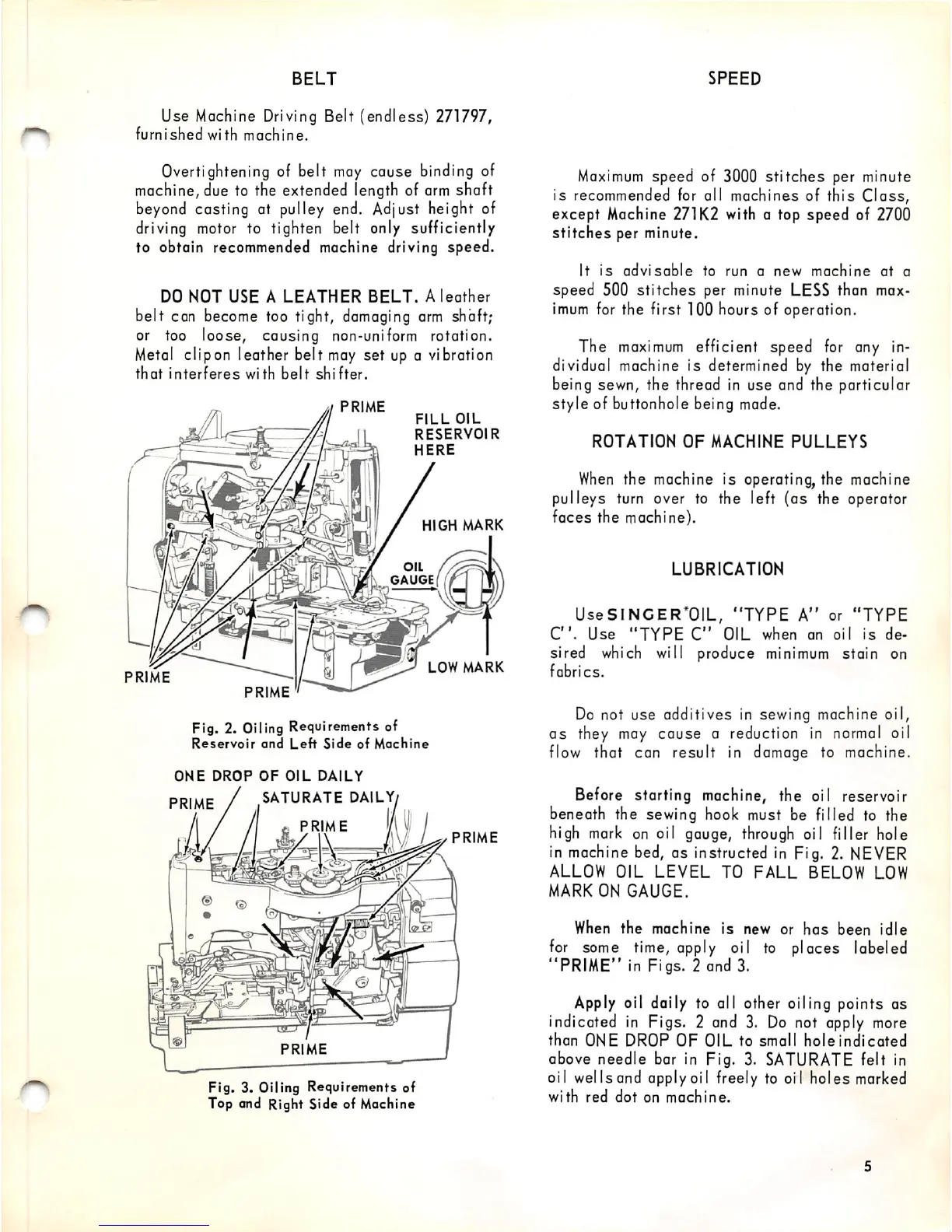

ONE

DROP

OF

OIL

DAILY

PRIME

PRIME

SATURATE

DAILY

PRIME

PRIME

FILL

OIL

RESERVOIR

HERE

HIGH

MARK

OIL

GAUGE

LOW

MARK

PRIME

Fig. 3. Oiling Requirements of

Top and Right Side of Mochine

SPEED

Maximum

speed of 3000

stitches

per minute

is recommended for all machines of

this

Class,

except

Machine

271K2

with

a top speed of 2700

stitches

per minute.

It

is

advisable

to run a

new

machine

at

a

speed 500

stitches

per minute LESS than max

imum

for the first 100 hours of operation.

The

maximum

efficient speed

for

any in

dividual machine is determined

by

the material

being sewn, the thread in use and the particular

style of buttonhole being made.

ROTATION

OF

MACHINE

PULLEYS

When

the

machine

is operating, the machine

pulleys turn over to the left (as the operator

faces

the machine).

LUBRICATION

UseSINCER'OIL,

"TYPE

A" or "TYPE

C".

Use

"TYPE

C"

OIL

when on

oil

is

de

sired which will produce

minimum

stain on

fabrics.

Do

not use additives in sewing machine oil,

as

they

may

cause a reduction in

normal

oil

flow that can result in damage to machine.

Before starting machine, the oil reservoir

beneath the sewing

hook

must be filled to the

high

mark

on

oil gauge,

through

oil filler hole

in

machine

bed,

as instructed in Fig. 2.

NEVER

ALLOW OIL

LEVEL

TO

FALL

BELOW LOW

MARK ON

GAUGE.

When

the

machine is new or

has

been

idle

for

some time, apply oil to places labeled

"PRIME" in Figs. 2 and 3.

Apply

oil daily to all other oiling points as

indicated in Figs. 2 and 3.

Do

not

apply

more

than

ONE

DROP

OF

OIL to

small

hole

indicated

above needle bar in Fig. 3. SATURATE felt in

oiI

wel

Is and applyoiI freely to oiI holes

marked

with

red

dot

on

machine.

Loading...

Loading...