KNIFE

GRINDER

701W51

Grinder

701W51

should be

set

to turn awoy

from

knife at a speed of approximately 2500

revolutions per minute.

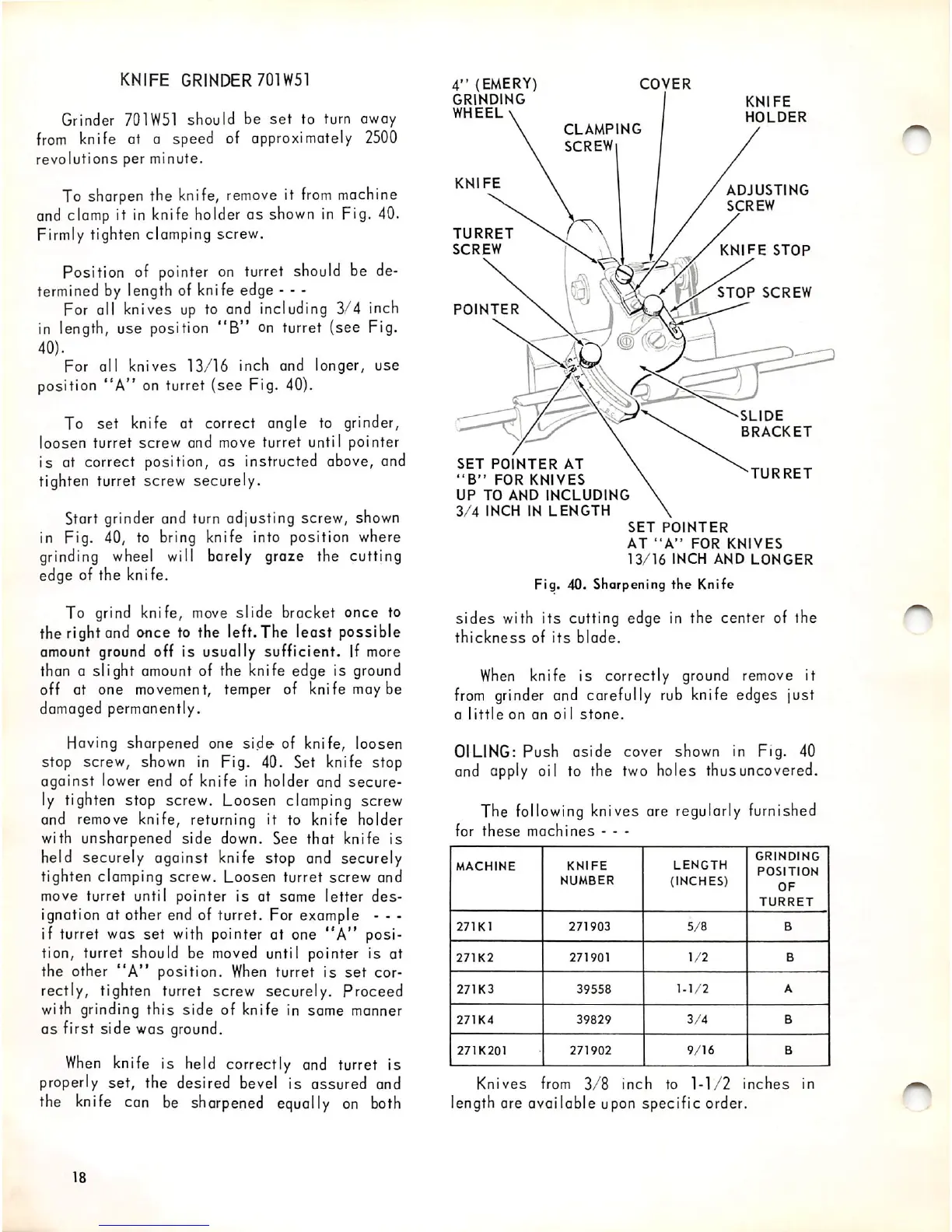

To sharpen the knife,

remove

it

from

machine

and

clamp

it in knife holder as shown in Fig.

40.

Firmly tighten clamping screw.

Position of pointer

on

turret should be de

termined by length of knife edge - - -

For all knives

up

to and including 3/4 inch

in length, use position

**B"

on turret (see Fig.

40).

For all knives 13/16 inch and longer, use

position

"A"

on turret (see Fig.

40).

To

set

knife at correct angle to grinder,

loosen turret screw end move turret until pointer

is at correct position, as instructed above, and

tighten turret screw securely.

Start grinder and turn adjusting screw,

shown

in Fig. 40, to bring knife into position where

grinding

wheel

will barely graze the cutting

edge of the knife.

To grind knife,

move

slide bracket once to

the right and once to the left. The least possible

amount ground off is usually sufficient. If more

than a slight

amount

of the knife edge is

ground

off at one movement, temper of knife may be

damaged permanently.

Having sharpened one

side

of knife, loosen

stop screw, shown in Fig. 40. Set knife stop

against lower end of knife in holder and secure

ly tighten stop screw. Loosen clamping screw

and remove knife, returning it to knife holder

with unshorpened side down. See that knife is

held securely against knife stop and securely

tighten clamping screw. Loosen turret screw and

move turret until pointer is at same letter

des

ignation at other end of turret. For example - - -

if turret was set

with

pointer at one

"A"

posi

tion, turret should be

moved

until pointer is at

the other

"A"

position.

When

turret is

set

cor

rectly, tighten turret screw securely. Proceed

with grinding this side of knife in same manner

as first side was

ground.

When

knife is held correctly

and

turret is

properly set, the desired bevel is assured and

the

knife

can

be

sharpened

equally

on

both

18

4"

(EMERY)

GRINDING

WHEEL

COVER

CLAMPING

SCREW

KNIFE

TURRET

SCREW

POINTER

SET

POINTER

AT

"B"

FOR

KNIVES

UP

TO

AND

INCLUDING

3/4

INCH

IN

LENGTH

KNIFE

HOLDER

ADJUSTING

SCREW

FE

STOP

STOP

SCREW

SLIDE

BRACKET

TURRET

SET

POINTER

AT

"A"

FOR

KNIVES

13/16

INCH

AND

LONGER

Fig. 40. Sharpening

the

Knife

sides

with

its

cutting edge in the center of the

thickness

of

its

blade.

When

knife is correctly ground remove it

from

grinder and carefully rub knife edges just

a

little

on

an

oi

1

stone.

OILING:

Push

aside

cover shown in Fig. 40

and apply oil to the two holes thus uncovered.

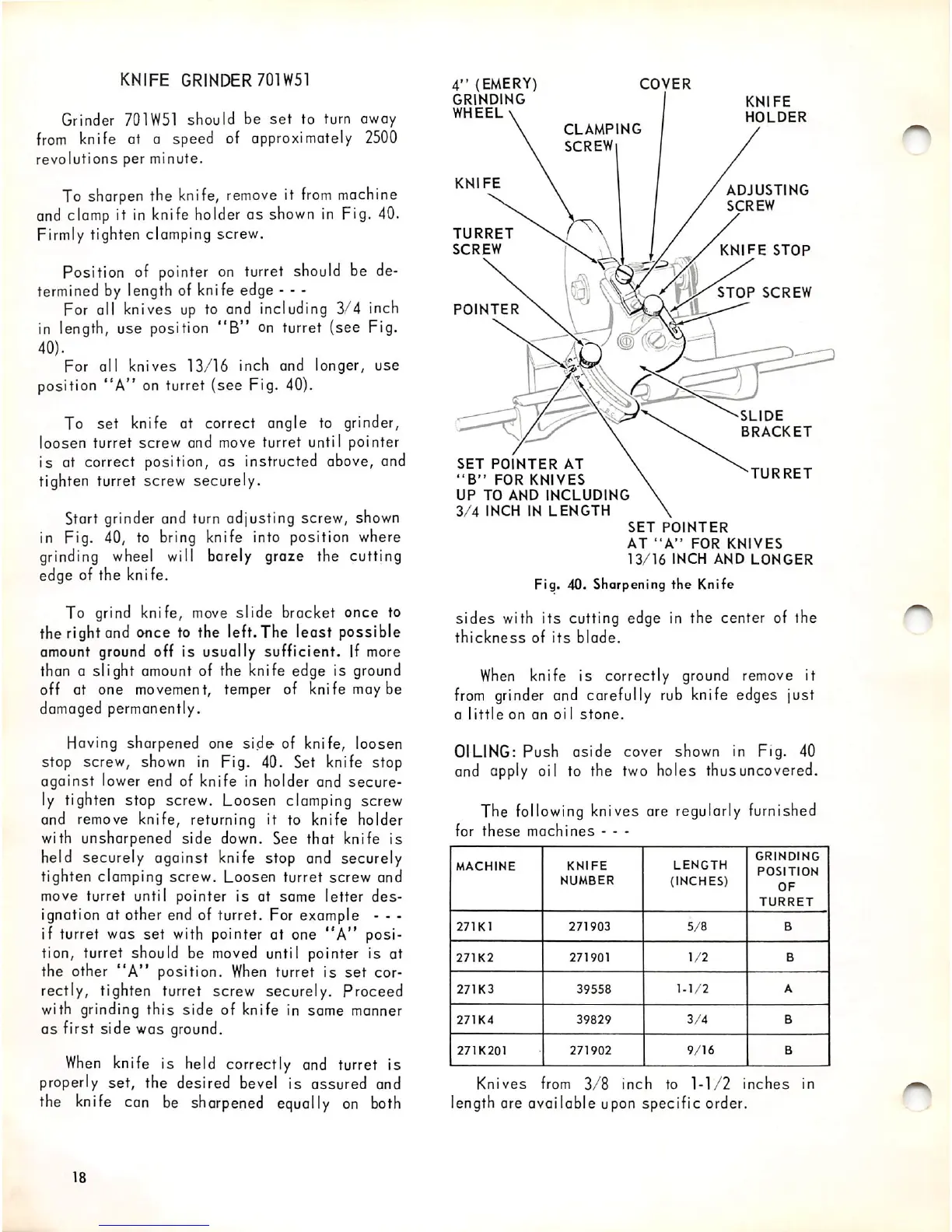

The

following

knives are regularly furnished

for

these

machines

- - -

MACHINE

KNIFE

NUMBER

LENGTH

(INCHES)

GRINDING

POSITION

OF

TURRET

271K1

271903

5/8

B

271K2

271901

1/2

B

271K3

39558

1-1/2

A

271K4

39829

3/4

B

271K201

271902

9/16

B

Knives

from

3/8

inch

to

1-1/2

inches

in

length are available upon specific order.

Loading...

Loading...